C-class non-sealed coil dry transformer

A dry-type transformer and coil technology, applied in the field of transformers, can solve the problems of non-flammability of the insulation system, loss of mechanical strength, unfavorable decomposition and recycling, etc., and achieves the effects of good heat dissipation conditions, simple manufacturing process, and overcoming high interlayer voltage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

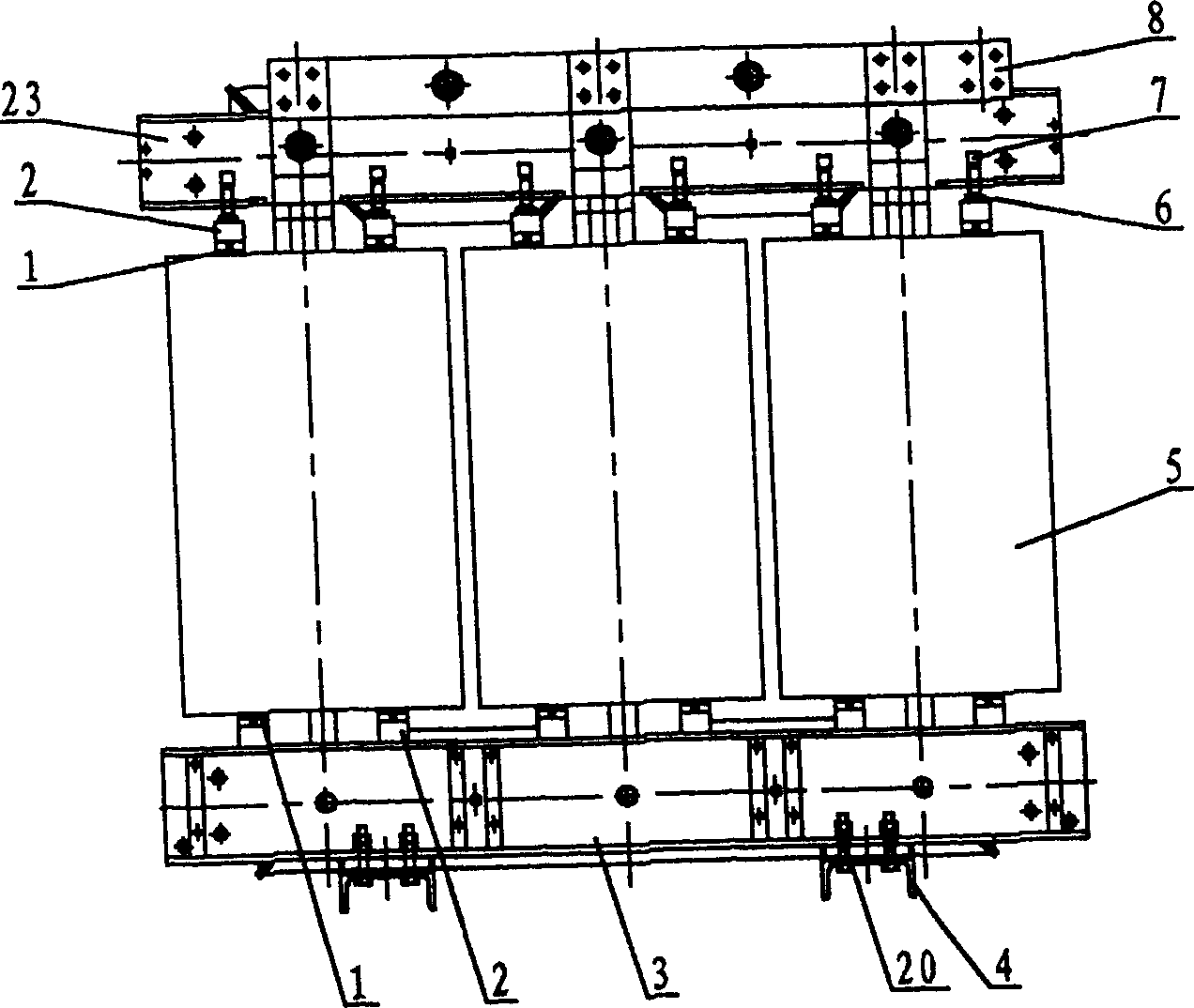

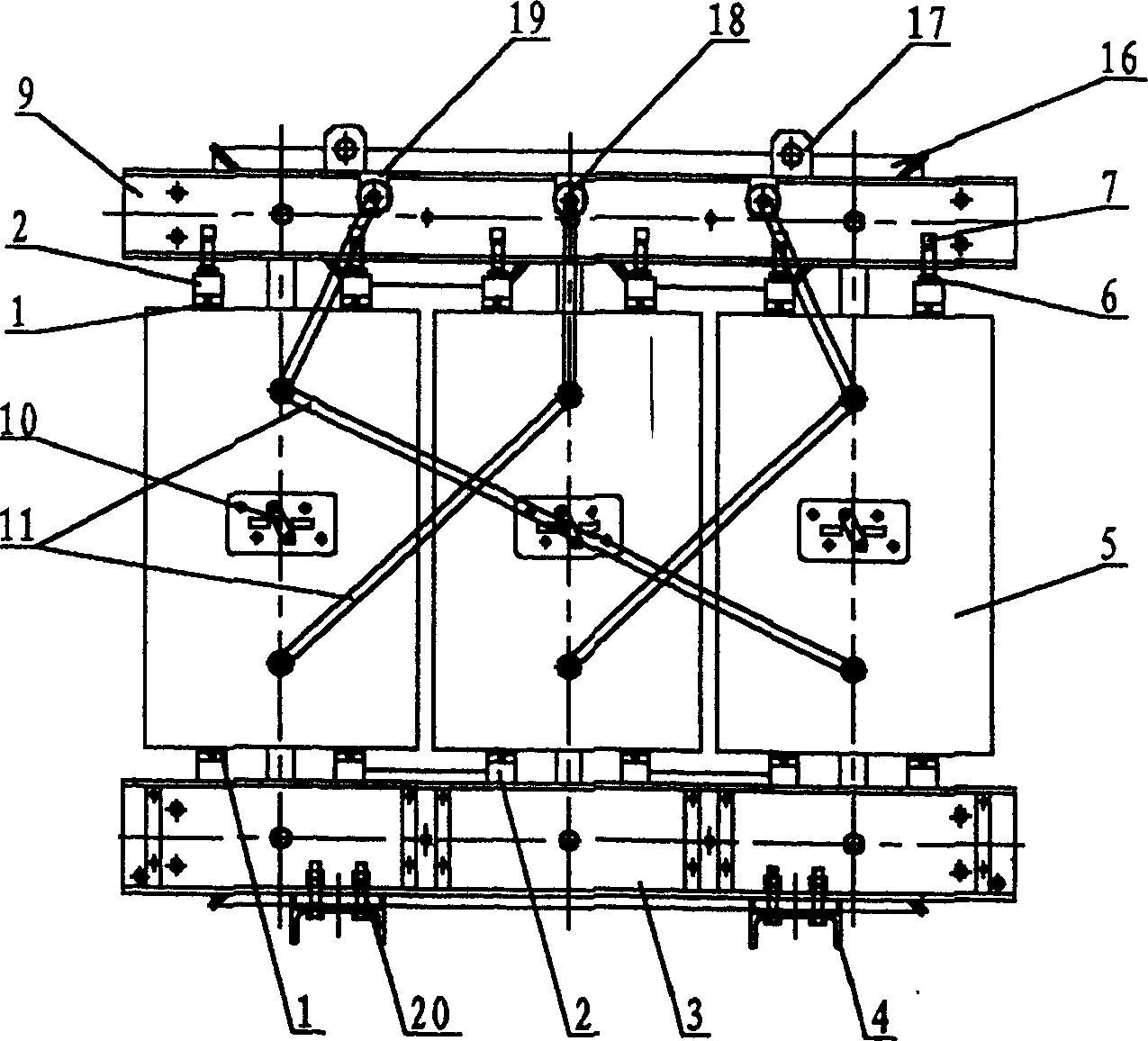

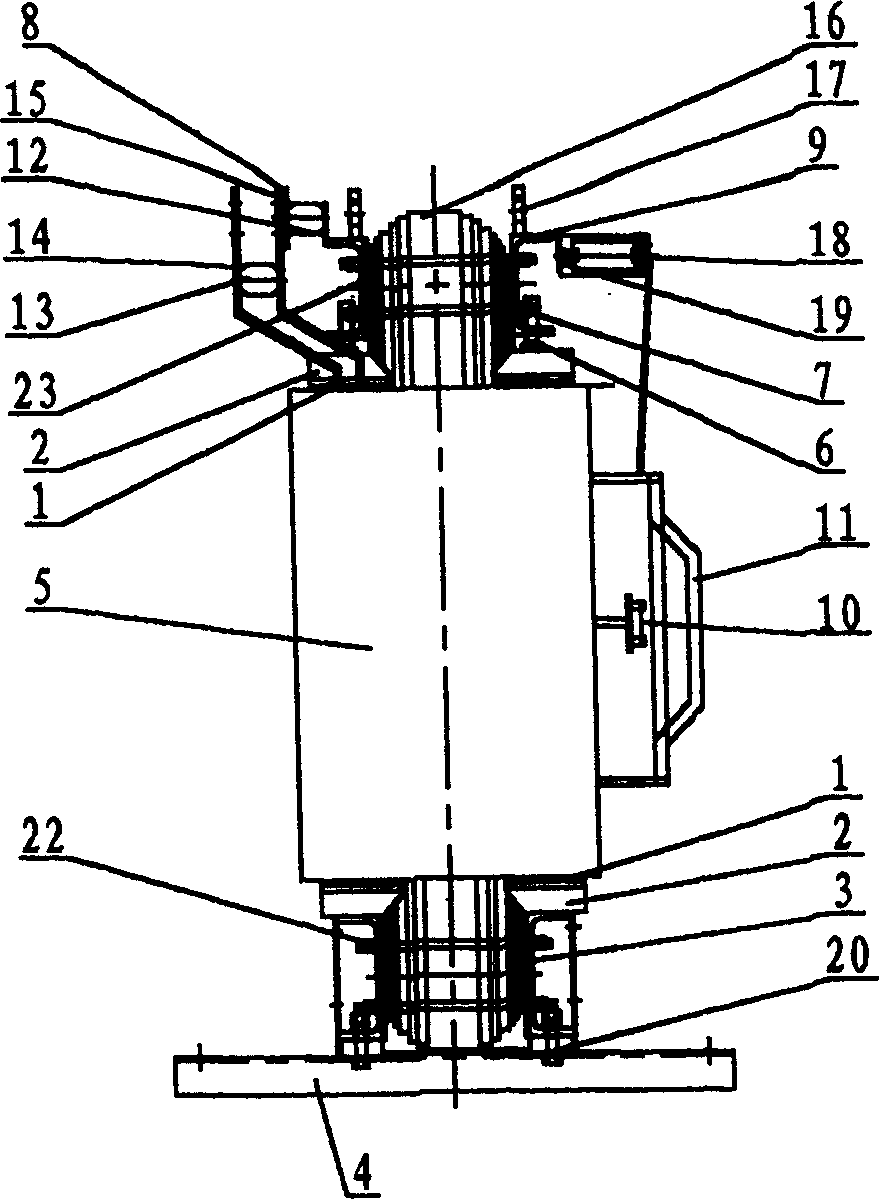

[0016] This embodiment is a three-phase Class C non-encapsulated coil dry-type transformer. The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

[0017] see Figure 1-Figure 8 , a C-class non-encapsulated coil dry-type transformer, including an iron core 16, a high-voltage coil 5 and a low-voltage coil 21, and silicon steel sheets with grain orientation and high magnetic permeability are laminated in five steps, and the iron core 16 is composed of 45° full seams The high-capacity low-voltage coil 21 made of copper foil is wound with insulating material with a temperature resistance of more than 220°C between the layers, and mica strips with a temperature resistance of more than 500°C constitute the cooling air passage, and the entire coil is solidified by vacuum pressure impregnation at high temperature. A rigid body; the high-voltage coil 5 is a continuous structure, which is composed of a C-grade glass fiber c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com