Process for preparing rapidly responsive pH sensitive hydrogel

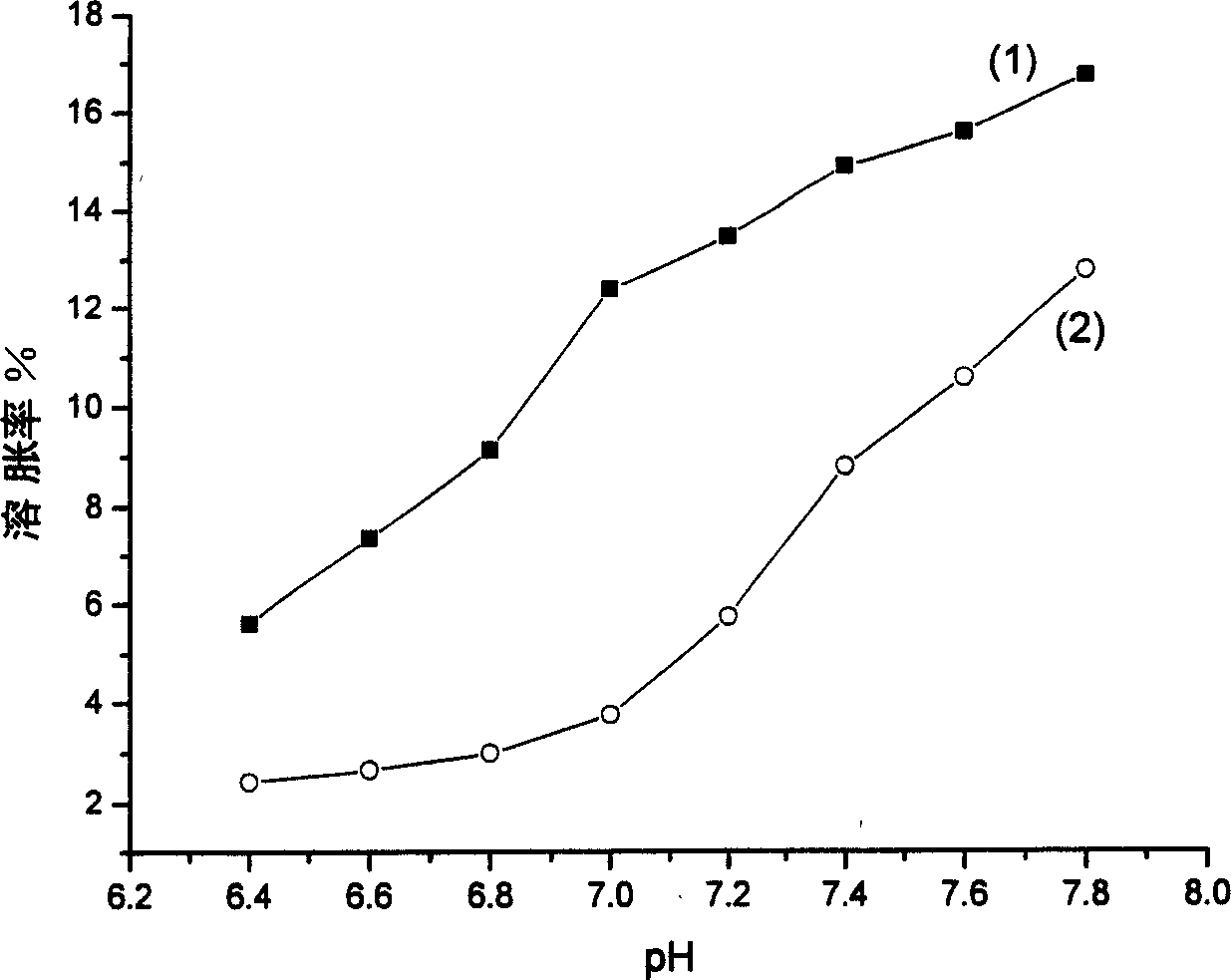

A fast-response, hydrogel technology, which is applied in the field of pH-sensitive hydrogel polymer material preparation, can solve the problems of easy residue and difficult removal of porogens, and achieve good biocompatibility and simple polymerization process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

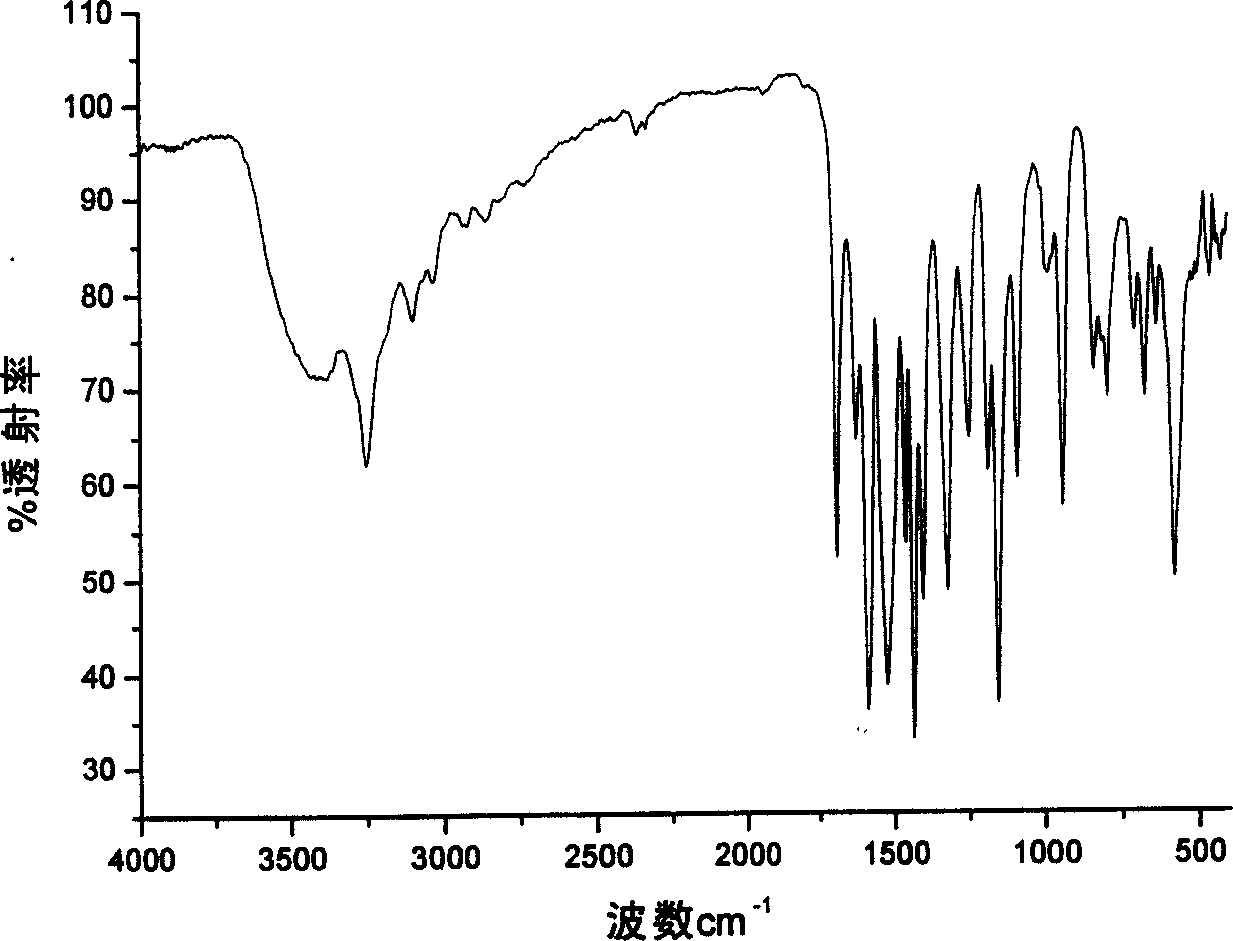

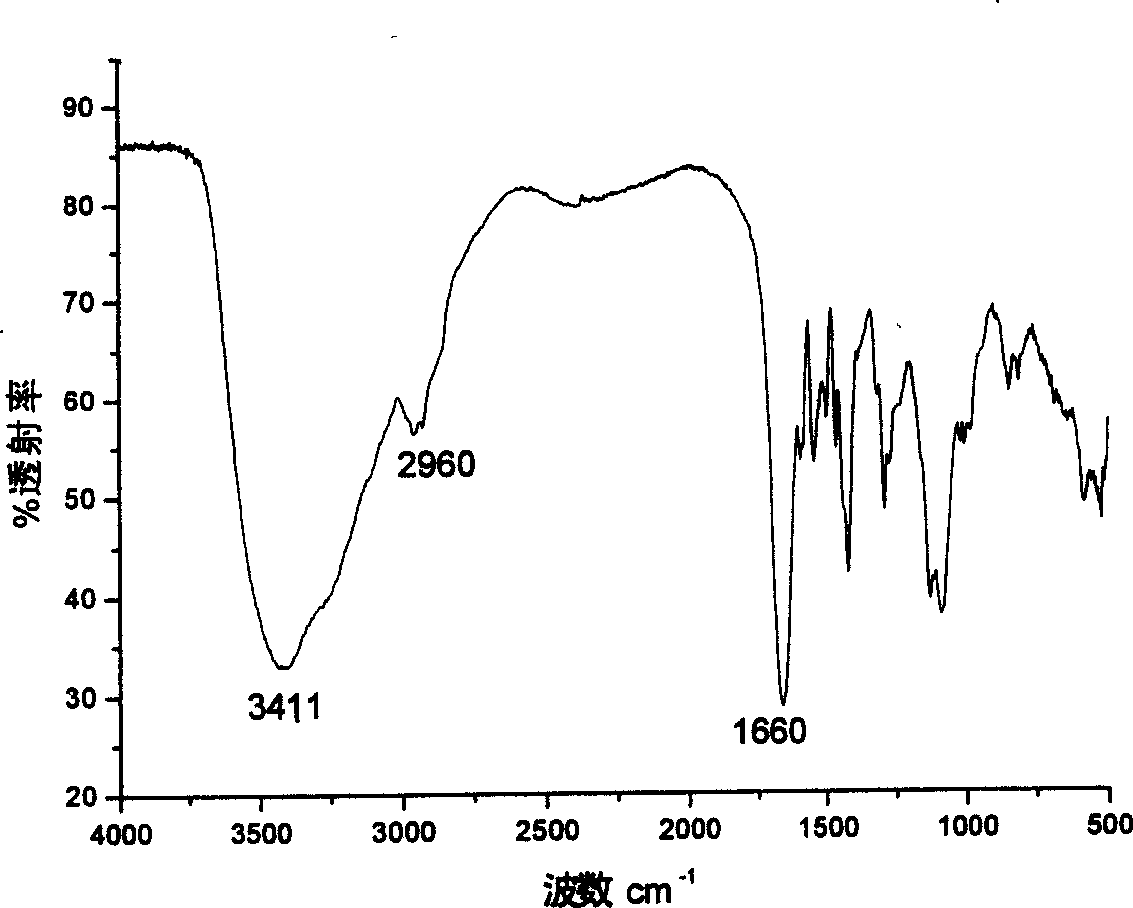

Embodiment 1

[0027] 5.3g sulfadiazine is dissolved in the aqueous solution and the acetone solution of the mass concentration 2%NaOH that volume ratio is 1: 1, pours in the four-neck flask that agitator, condensing tube and thermometer are housed, stirs at constant speed, and with ice-water bath Cool to keep the reaction temperature below 5°C. After the temperature is constant, gradually add 2g of acryloyl chloride dropwise, keep the temperature below 10°C for 1-3 hours, stop the experiment, and discharge. The precipitated product was filtered and washed three times with distilled water to remove unreacted monomer impurities to obtain a milky yellow solid, which was vacuum-dried at room temperature for 24 h to obtain a yellow powder.

[0028] 0.366g N-vinylpyrrolidone monomer, 0.534g sulfonamide monomer, 0.009g crosslinking agent N, N-methylenebisacrylamide, 0.0096g initiator azobisisobutyronitrile were dissolved in 5ml dimethyl sulfoxide, After stirring evenly, quickly pour it into a test...

Embodiment 2

[0029] Embodiment 2: Dissolve 0.366g N-vinylpyrrolidone monomer, 0.534g sulfonamide monomer, 0.018g crosslinking agent N, N-methylenebisacrylamide, 0.0096g initiator azobisisobutyronitrile in Example 1 5ml of dimethyl sulfoxide, stirred evenly and quickly poured into a test tube with a diameter of 20cm. After sealing the test tube, put it into a water bath whose temperature was previously controlled at 65° C. for constant temperature heating reaction for 10 h. After the reaction, the prepared sensitive hydrogel was taken out of the test tube, soaked in deionized water for 24 hours, washed thoroughly to remove impurities such as unreacted monomers, cross-linking agents and solvents, and dried in a vacuum oven for 3-5 hours. days to obtain the prepared hydrogels.

Embodiment 3

[0030] Embodiment 3: Dissolve 0.366g N-vinylpyrrolidone monomer, 0.534g sulfonamide monomer, 0.036g crosslinking agent N, N-methylenebisacrylamide, 0.0096g initiator azobisisobutyronitrile in Example 1 5ml of dimethyl sulfoxide, stirred evenly and quickly poured into a test tube with a diameter of 20cm. After the test tube was sealed, it was put into a water bath whose temperature was previously controlled at 65° C. for a constant temperature heating reaction for 6 h. After the reaction, the prepared sensitive hydrogel was taken out of the test tube, soaked in deionized water for 24 hours, washed thoroughly to remove impurities such as unreacted monomers, cross-linking agents and solvents, and dried in a vacuum oven for 3-5 hours. days to obtain the prepared hydrogels.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com