Polymer, pH-sensitive nano vesicle, and preparation method and application thereof

A nanovesicle and polymer technology, applied in the fields of polymer chemistry and biomedical engineering, can solve the problems of insufficient pH sensitivity of the medium, difficult to control the mutation range, wide mutation range, etc. The effect of accelerated rate and fast response rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0095] Preparation of PyDH:

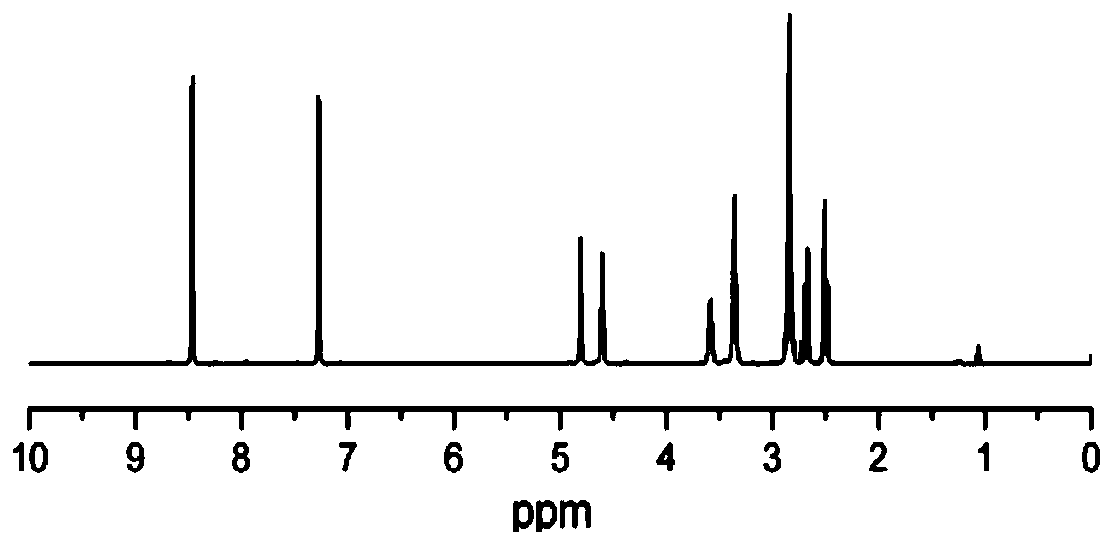

[0096] Under dry argon, dissolve 21.03g 4-vinylpyridine and 21.63g 3-mercapto-1,2-propanediol in 100mL DMF, add 0.65g N,N-diisopropylethylamine, stir at room temperature for 24h, and then Diethyl ether (~5°C) was settled, filtered with suction, and vacuum-dried at room temperature to constant weight to obtain the single-ended dihydroxypyridine compound PyDH (41.35 g, yield 96.9%). 1 H NMR as figure 1 shown.

Embodiment 1

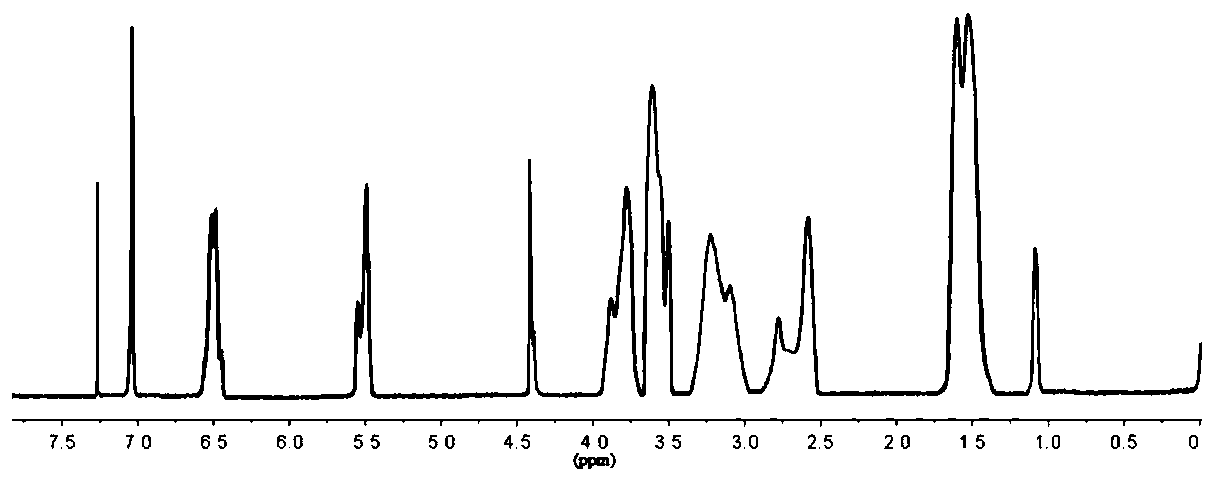

[0098] (1) Preparation of Polymer A1

[0099] 10.4 g of compound PyDH, 25.59 g of hexamethylene diisocyanate-1,4-butanediol-hexamethylene diisocyanate and 0.2 g of dibutyltin dilaurate were dissolved in 50 mL of N,N'-dimethylformamide ( DMF), the oil bath was heated to 80°C for a constant temperature reaction for 3.5h. Then cool to 22°C, add chitosan oligosaccharide (number average molecular weight 1610, degree of deacetylation: 90%) in DMF solution (80.5g chitosan oligosaccharide+100mL DMF), maintain the temperature and continue the reaction for 2.5h. After the reaction, add DMF solution to the reaction flask to dilute to 0.25g / mL, then settle with eight times the volume of deionized water, repeat twice, filter with suction, and vacuum dry at 50°C to constant weight to obtain polymer A1. 1 H NMR as figure 2 shown.

[0100] (2) Preparation of Polymer B1

[0101] Dissolve 6.82g of polymer A1 in 50mL of anhydrous chloroform, add 3.6g of acetaldehyde phosphorylcholine, and r...

Embodiment 2

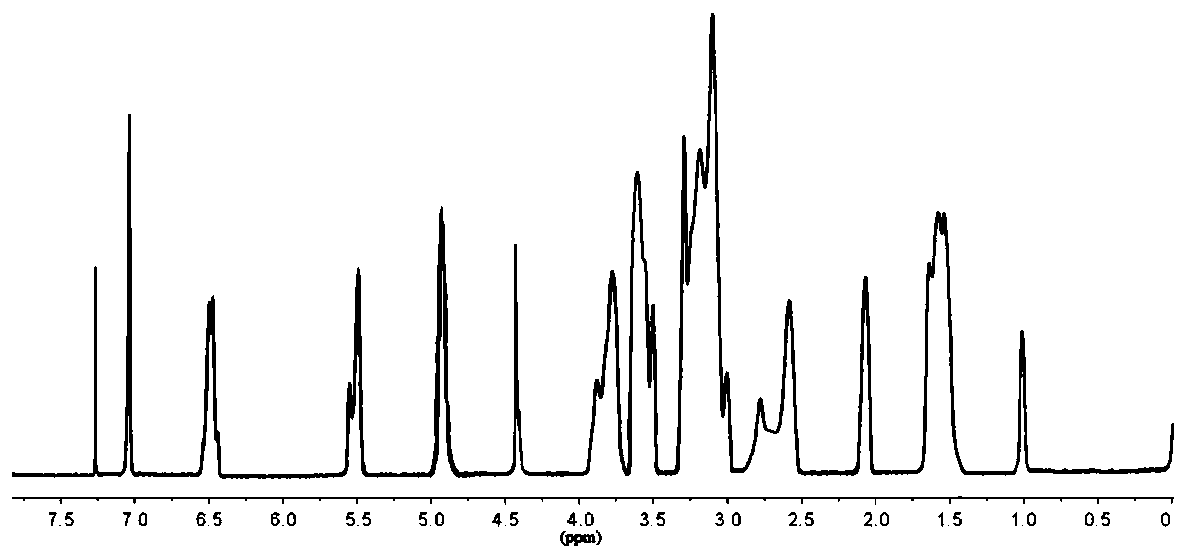

[0107] (1) Preparation of Polymer A2

[0108] 10.4 g of compound PyDH, 22.5 g of tetramethylene diisocyanate-1,4-butanediol-hexamethylene diisocyanate and 0.18 g of dibutyltin dilaurate were dissolved in 50 mL of N,N'-dimethylformamide ( DMF), the oil bath was heated to 75°C for constant temperature reaction for 3h. Then cool to 25° C., add a DMF solution (80.5 g chitooligosaccharide + 100 mL DMF) of chitosan oligosaccharide (number average molecular weight 1610, deacetylation degree: 90%), and maintain the temperature to continue the reaction for 2.5 h. After the reaction, add DMF solution to the reaction bottle to dilute to 0.25g / mL, then settle with eight times the volume of deionized water, repeat twice, filter with suction, and vacuum dry at 50°C to constant weight to obtain polymer A2.

[0109] (2) Preparation of Polymer B2

[0110] Dissolve 6.51g of polymer A2 in 50mL of anhydrous chloroform, add 3.6g of acetaldehyde phosphorylcholine, and react at a constant temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com