Preparation method of physically-crosslinked chitosan-based hydrogel with efficient pH sensitivity and high mechanical strength

A technology of mechanical strength and chitosan, which is applied in the field of preparation of physically cross-linked chitosan-based hydrogel, can solve the problems of poor mechanical properties and slow response to external stimuli, and achieve strong mechanical properties, easy mixing and heat dissipation , the effect of mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

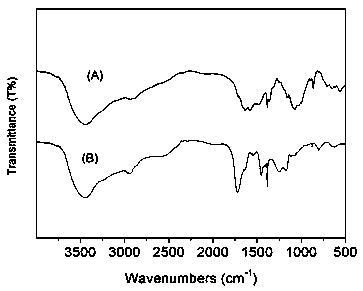

[0035] The preparation of the physically cross-linked chitosan-based hydrogel with efficient pH sensitivity and high mechanical strength shown in embodiment 1. formula (I)

[0036] In step (1), at room temperature, 1.0 g of chitosan represented by formula (III) was dissolved in 10 mL of 1% acetic acid solution by mass fraction, and stirred overnight to prepare a transparent chitosan solution.

[0037] Step (2), add the monomer DMAEMA shown in the formula (II) and the monomer AAC shown in the formula (IV) (mass ratio is 2.5:97.5) into the round bottom flask, mix in 0 ℃ (ice-water bath) uniform.

[0038] Step (3), adding the potassium persulfate-sodium thiosulfate redox initiator with a mass concentration of 0.16% in the step (1) system, then adding the monomer mixture obtained in step (2), stirring evenly with a magnet and passing through Deoxygenate with nitrogen for 15 minutes.

[0039] In step (4), the reaction mixture prepared in step (3) is poured into a small test tube ...

Embodiment 2

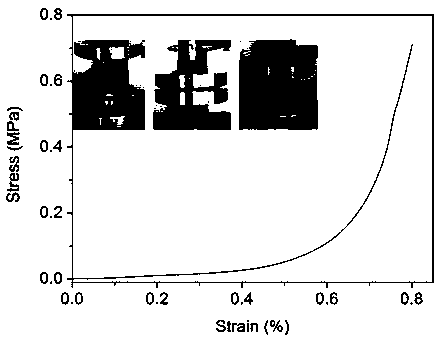

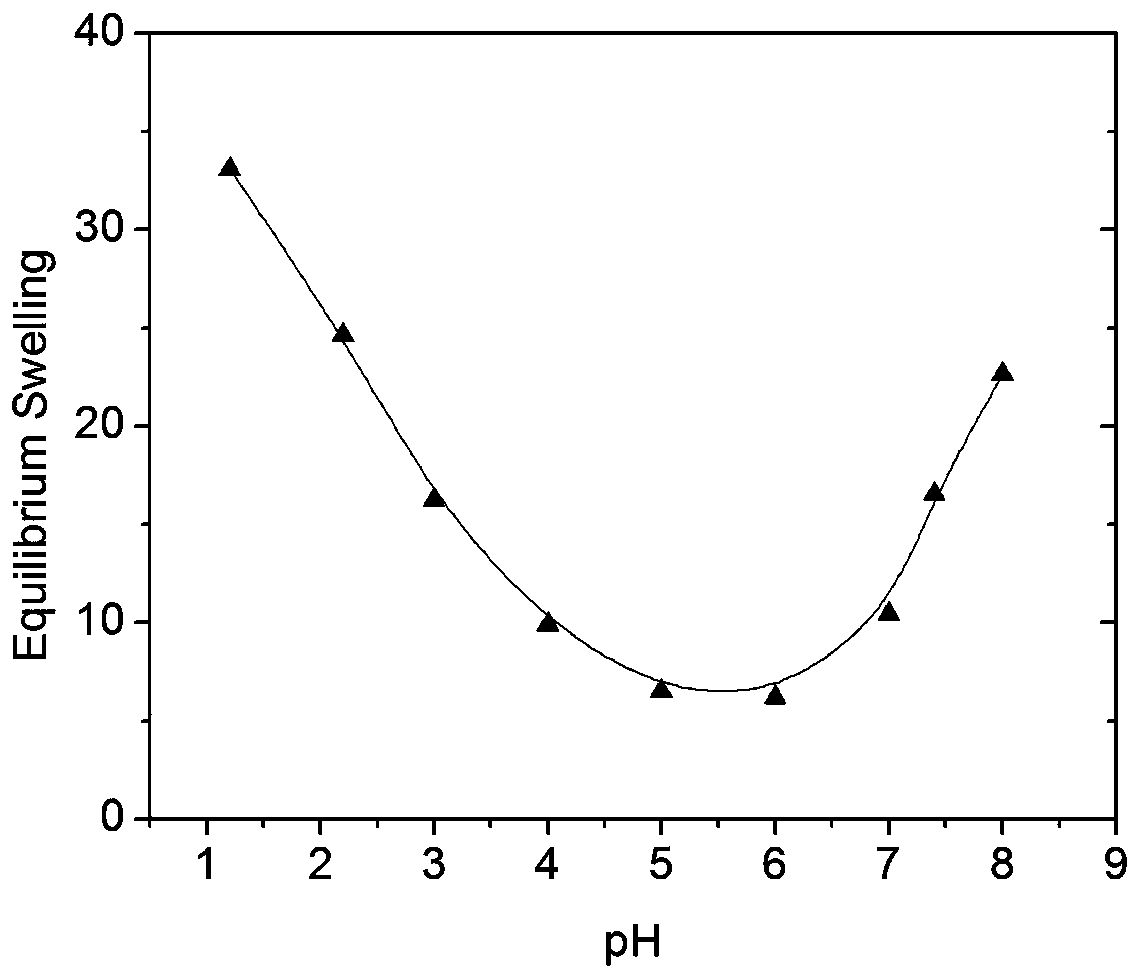

[0043] Embodiment 2. As described in Example 1, the difference is that the quality of chitosan shown in the change formula (III) is 2g, the swelling ratio of the gel becomes 16.43, and the maximum compressive strength becomes 0.0326MPa.

Embodiment 3

[0044] Embodiment 3. As described in Example 1, the difference is that the mass ratio of monomer DMAEMA shown in changing formula (II) and monomer AAC shown in formula (IV) is 5:95, and the swelling rate of gel becomes 22.79, and the maximum compressive strength becomes 0.1309MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com