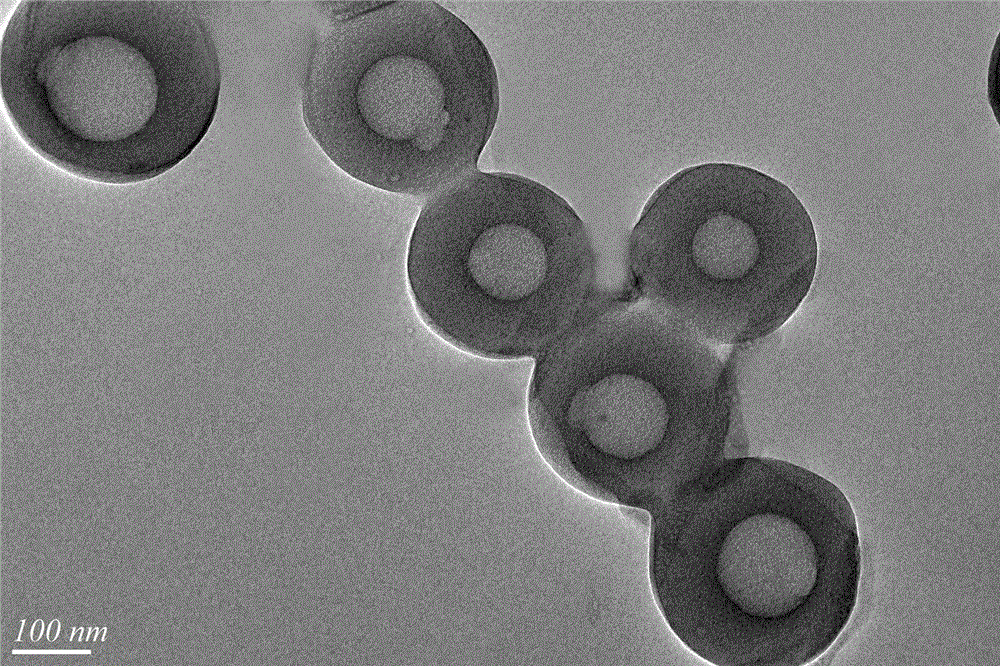

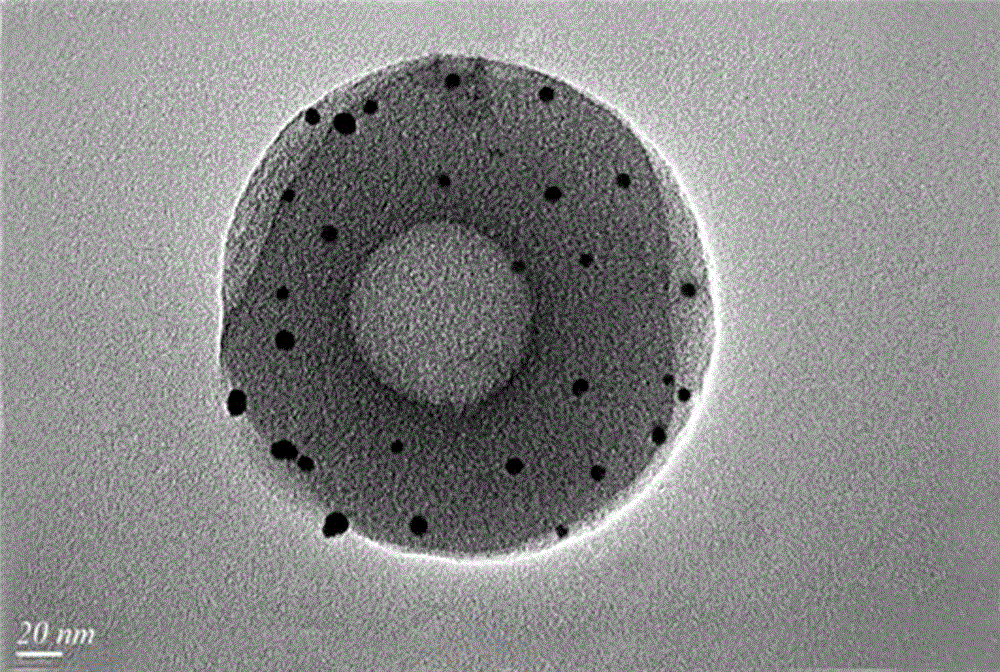

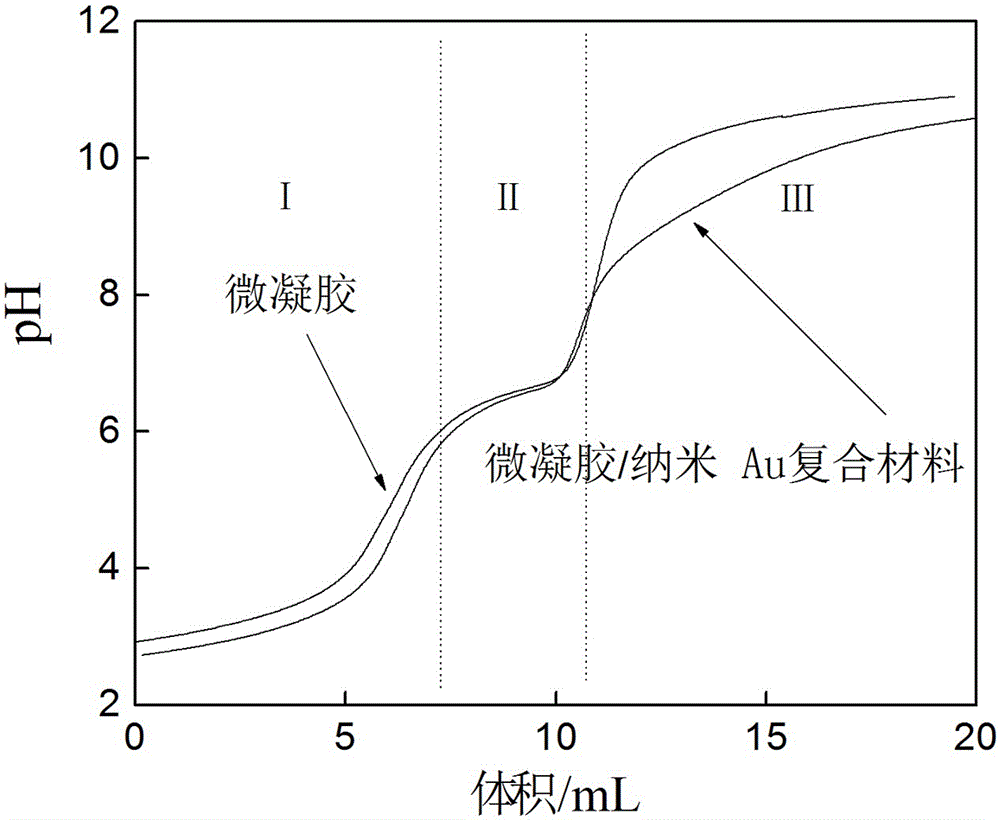

Preparation method of core-shell type cationic microgel-nano noble metal composite material

A composite material and microgel technology, which is used in the preparation of pH-sensitive core-shell cationic microgel-loaded nano-noble metal composite materials, can solve the problems of weak polymer reduction, low glass transition temperature, and easy film formation , to achieve the effects of shortening the transmission distance, improving catalytic efficiency and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Weigh 0.09g of SDS, add it into 45mL of water, sonicate for 10min, transfer it into a four-neck flask with a stirring device, add 0.6g of PEGMA (Mn≈2080), and pass through N 2 , 250r / min stirring and emulsifying for 20min.

[0037] Weigh 0.03g DVB, mix it with 2g DEAMA and 1g MMA, and ultrasonically mix it evenly. Add the mixed solution into a constant pressure dropping funnel, drop it into a four-neck flask at a dropping rate of 0.3 mL / min, stir for 2 hours to make it uniform, and raise the temperature to 65°C.

[0038] 0.03g (NH 4 ) 2 S 2 o 8 Dissolve it in 5mL of water, add it to a constant pressure dropping funnel, and drop it into a four-necked bottle at a rate of 0.25mL / min. After the dropwise addition, it was reacted for 12 hours to generate PMMA / PDEAMA microgel white emulsion.

[0039] The prepared PMMA / PDEAMA microgel was dialyzed with deionized water until the conductivity of the dialyzed aqueous solution no longer changed, so as to remove unreacted mono...

Embodiment 2

[0049] Weigh 0.10g of SDS, add 45mL of water, ultrasonic for 10min, transfer to a four-neck flask with a stirring device, add 0.5g of PEGMA (Mn≈2080), pass through N 2 , stirring and emulsifying at 180r / min for 30min.

[0050] Weigh 0.06g DVB, mix it with 2g VP, 1g MMA, and ultrasonically mix it evenly. Add the mixed solution into a constant pressure dropping funnel, drop it into a four-neck flask at a dropping rate of 0.3 mL / min, stir for 2 hours to make it uniform, and raise the temperature to 65°C.

[0051] 0.045g K 2 S 2 o 8 Dissolve it in 5mL of water, add it to a constant pressure dropping funnel, and drop it into a four-necked bottle at a rate of 0.25mL / min. After the dropwise addition, react for 12 hours to generate PMMA / PVP microgel emulsion.

[0052] The prepared PMMA / PVP microgel was dialyzed with deionized water until the conductivity of the dialyzed aqueous solution no longer changed, so as to remove unreacted monomers, macromolecular stabilizers and surfacta...

Embodiment 3

[0056] Weigh 0.12g of SDS, add it into 50mL of water, sonicate for 10min, transfer it into a four-necked flask with a stirring device, add 0.6g of PEGMA (Mn≈475), and pass N 2 , Stir and emulsify at 180r / min for 20min.

[0057] Weigh 0.03g EGDMA, mix it with 2g DEAMA and 1g MMA, and ultrasonically mix it evenly. Add the mixed solution into a constant pressure dropping funnel, drop it into a four-neck flask at a dropping rate of 0.3 mL / min, stir for 2 hours to make it uniform, and raise the temperature to 65°C.

[0058] Dissolve 0.03g of V-50 in 5mL of water, add it to a constant pressure dropping funnel, and drop it into a four-neck flask at a rate of 0.25mL / min. After the dropwise addition, it was reacted for 12 hours to generate PMMA / PDEAMA microgel white emulsion.

[0059] The prepared PMMA / PDEAMA microgel was dialyzed with deionized water until the conductivity of the dialyzed aqueous solution no longer changed, so as to remove unreacted monomers, macromolecular stabiliz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com