Nano microgel and its preparing process and use

A microgel and nanotechnology, applied in the direction of pharmaceutical formulations, etc., can solve the problems of inconvenient preparation, unstable system, no protein and polysaccharide to prepare microgels, etc., achieving good embedding effect, good edible absorption effect, The effect of broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0044] Example 1. Ovalbumin (Ovalbumin) and egg white lysozyme (Lysozyme) form microgels in alkaline aqueous solution.

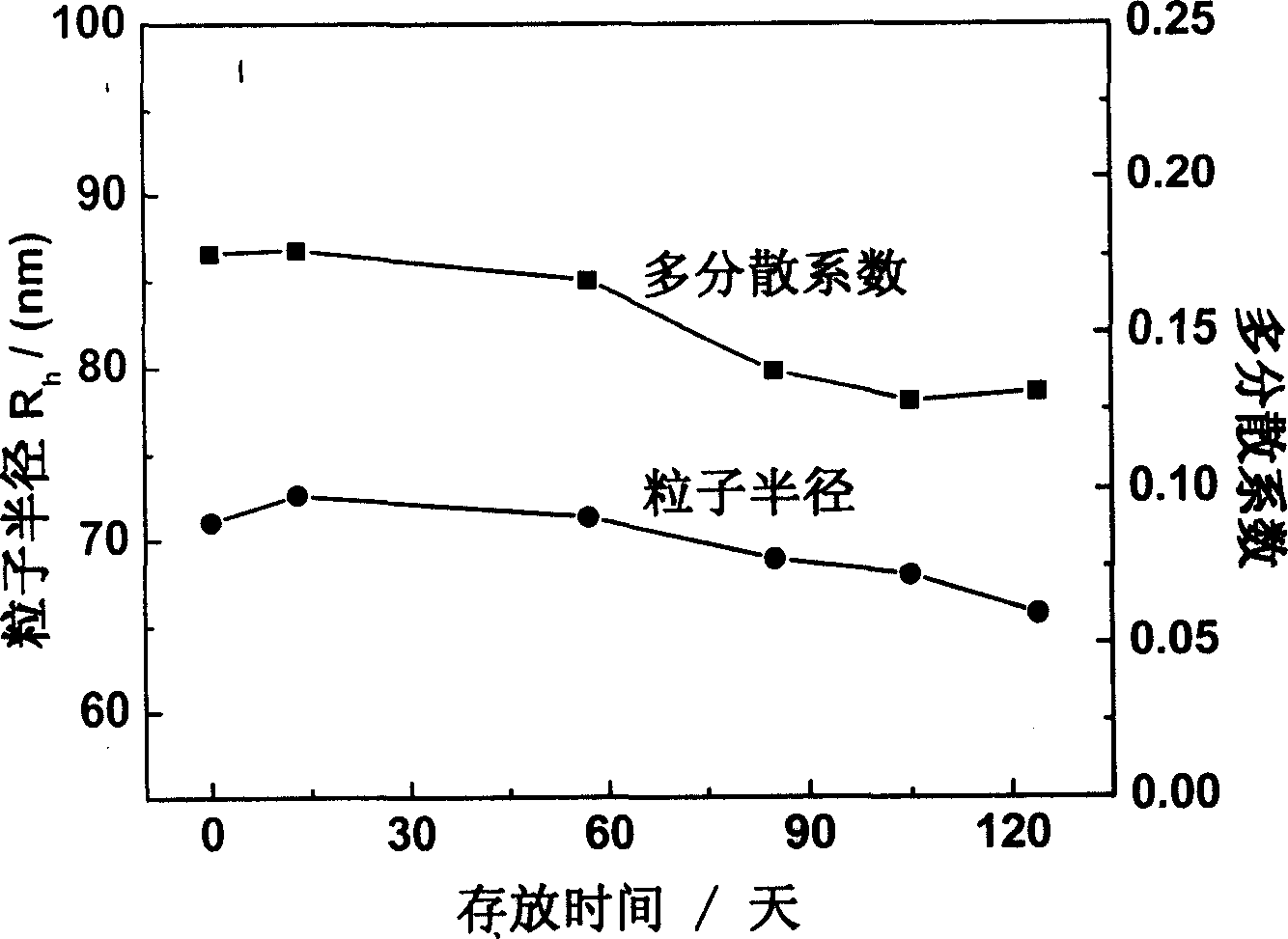

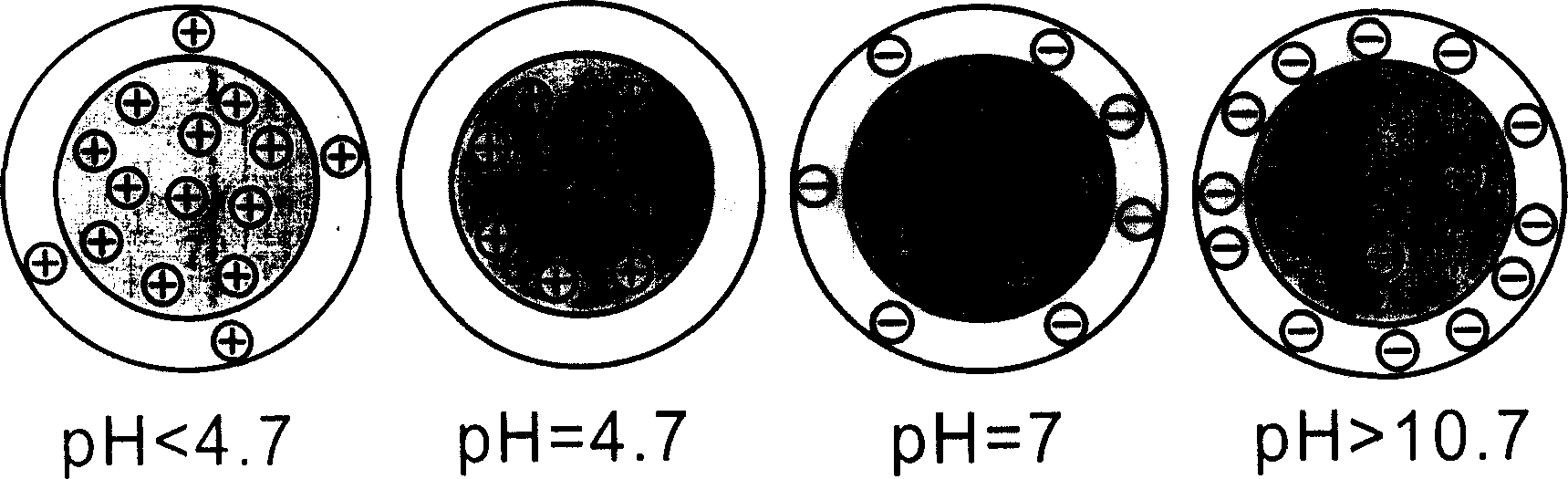

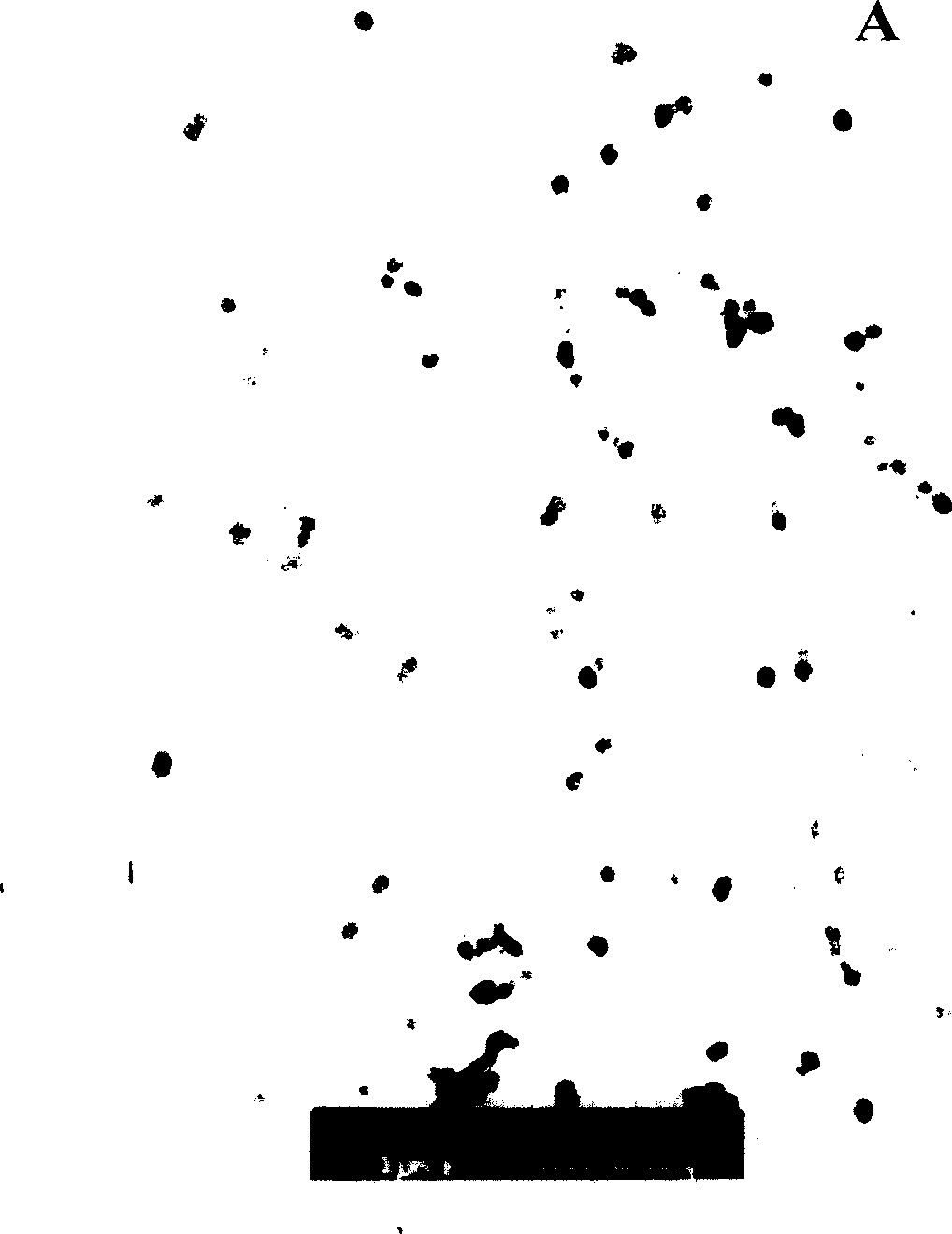

[0045] Ovalbumin and egg white lysozyme were dissolved in deionized water to prepare 2mg / mL and 0.624mg / mL protein solutions. Under magnetic stirring, 1.2 mL of albumin aqueous solution was added dropwise to 3 mL of lysozyme aqueous solution, and the pH of the solution was adjusted to 10.3 with 0.1 mol / L NaOH and stirred for 60 minutes to make it evenly mixed. Then the mixed solution was placed in a water bath at 80°C and heated for 1.5 hours to obtain a stable microgel solution. Measure the obtained microgel solution with dynamic laser light scattering: the average particle diameter is 147nm, and the polydispersity coefficient is 0.127 ( Figure 4 ). The transmission electron microscope measured that the average particle size of the microgel was only 80nm ( image 3 ). The microgel solution is extremely stable, and there is no obvious change after 120 d...

example 2

[0048] Example 2. Ovalbumin (Ovalbumin) and egg white lysozyme (Lysozyme) form microgels in acidic aqueous solution.

[0049] Ovalbumin and lysozyme were dissolved in deionized water to prepare 2mg / mL and 0.624mg / mL protein solutions. Under magnetic stirring, add 600 μL of albumin aqueous solution dropwise to 3 mL of lysozyme aqueous solution, adjust the pH of the solution to 10.0 with 0.06mol / L NaOH and stir for 3 minutes to make it evenly mixed, and then quickly add 0.01mol / L HCl The pH of the solution was adjusted to 5.0, and then the mixed solution was quickly placed in a water bath at 80° C. and heated for 10 minutes to obtain a stable microgel solution. The obtained microgel solution was measured by dynamic laser light scattering: the average particle diameter was 71.4 nm, and the polydispersity coefficient was 0.224.

[0050] In the above system, if the molar ratio of albumin to lysozyme is controlled within the range of 0.05-5, and the pH of the solution is adjusted w...

example 3

[0051] Example 3. Bovine Serum Albumin (Bovine Serum Albumin) and lysozyme (Lysozyme) form microgels in alkaline or acidic aqueous solutions.

[0052] Dissolve bovine serum albumin and lysozyme in deionized water respectively to prepare 2.838mg / mL and 0.624mg / mL protein solutions. Under magnetic stirring, 1.5 mL of bovine serum albumin aqueous solution was added dropwise to 3 mL of lysozyme aqueous solution, and the pH of the solution was adjusted to 8.90 with 0.1 mol / L NaOH and stirred for 15 minutes to make it evenly mixed. Then the mixed solution was placed in a water bath at 80°C and heated for 1 hour to obtain a stable microgel solution. The obtained microgel solution was measured by dynamic laser light scattering: the particle size was 151.8 nm, and the polydispersity coefficient was 0.0880.

[0053] In the above system, the molar ratio of bovine serum albumin and lysozyme is controlled within the range of 0.05 to 5, and the pH of the solution is adjusted to the range o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Average particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com