Method for fast preparing single crystal tellurium in one dimension Nano structure from powder of fellurium

A nanostructure, single crystal technology, applied in the direction of single crystal growth, single crystal growth, chemical instruments and methods, etc., can solve the problems of long reaction time, high temperature and high pressure, high cost, etc., and achieve the effect of simple and easy-to-obtain raw materials and mild conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Example 1. Preparation of one-dimensional nanostructure single crystal tellurium

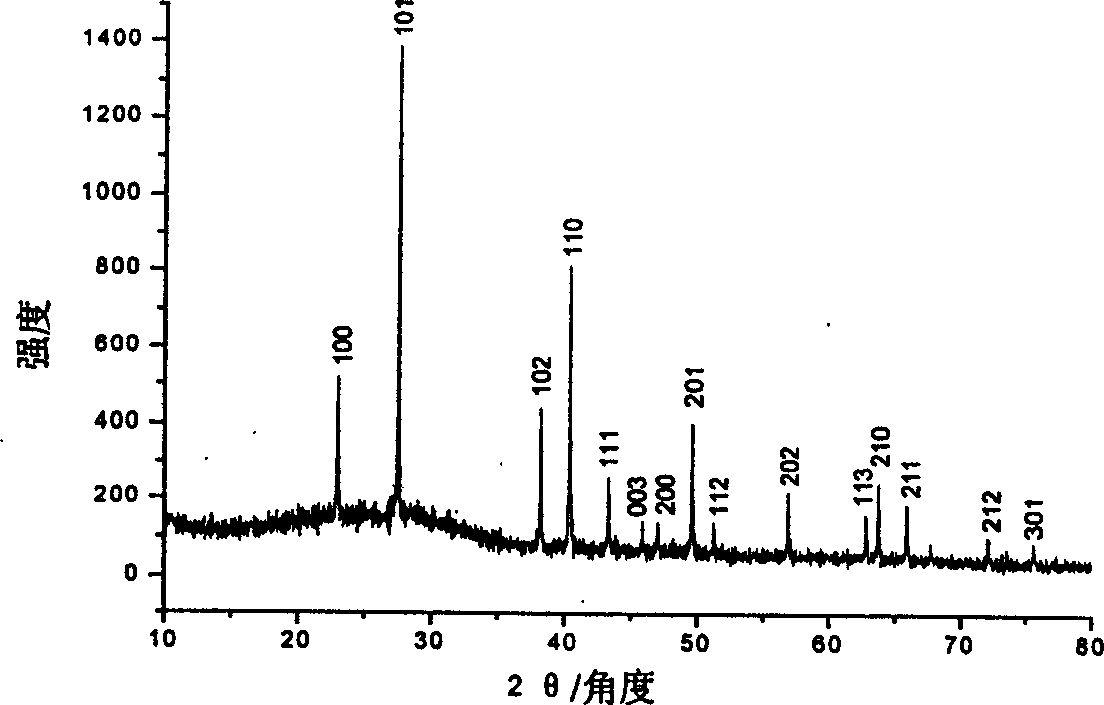

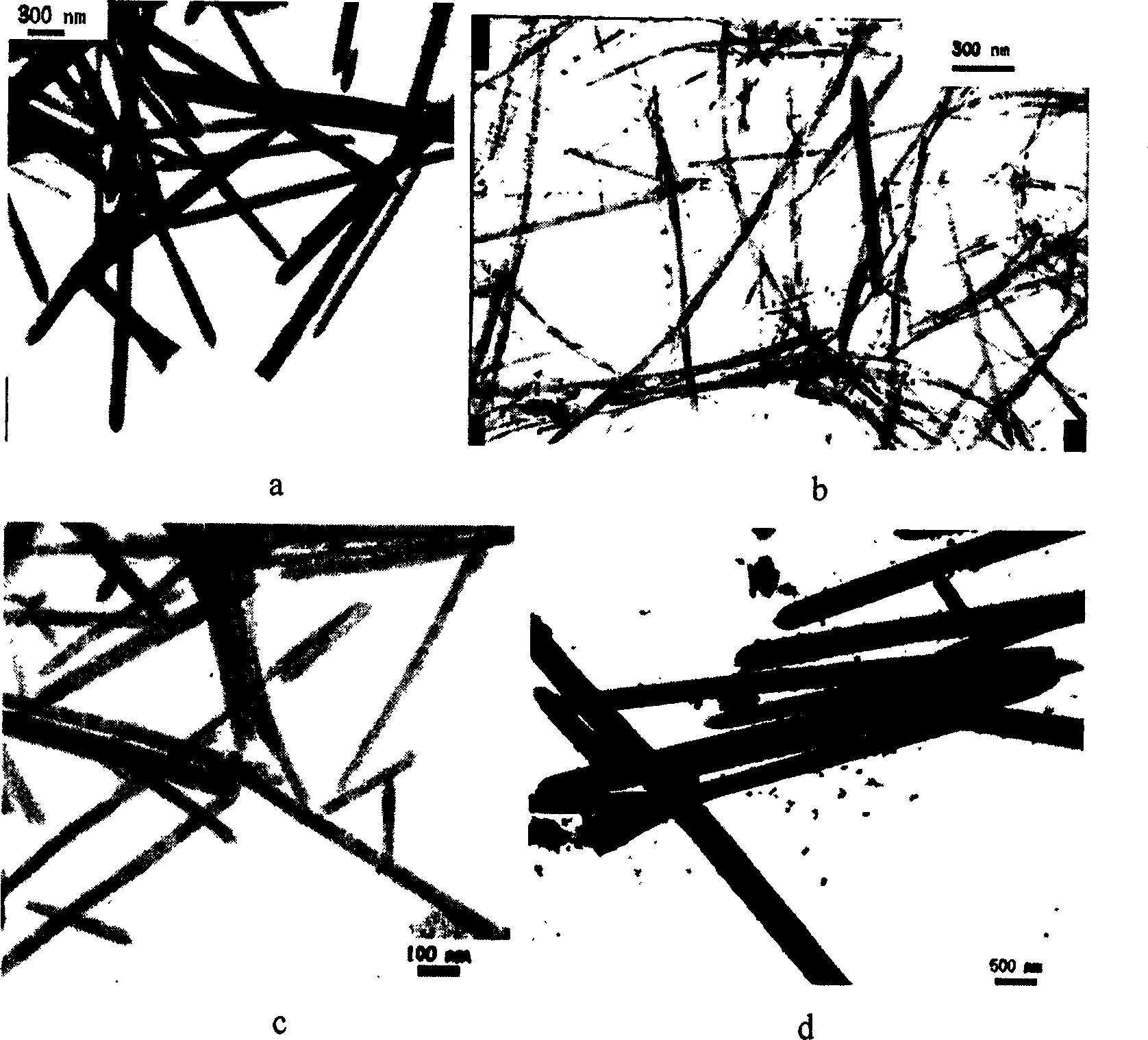

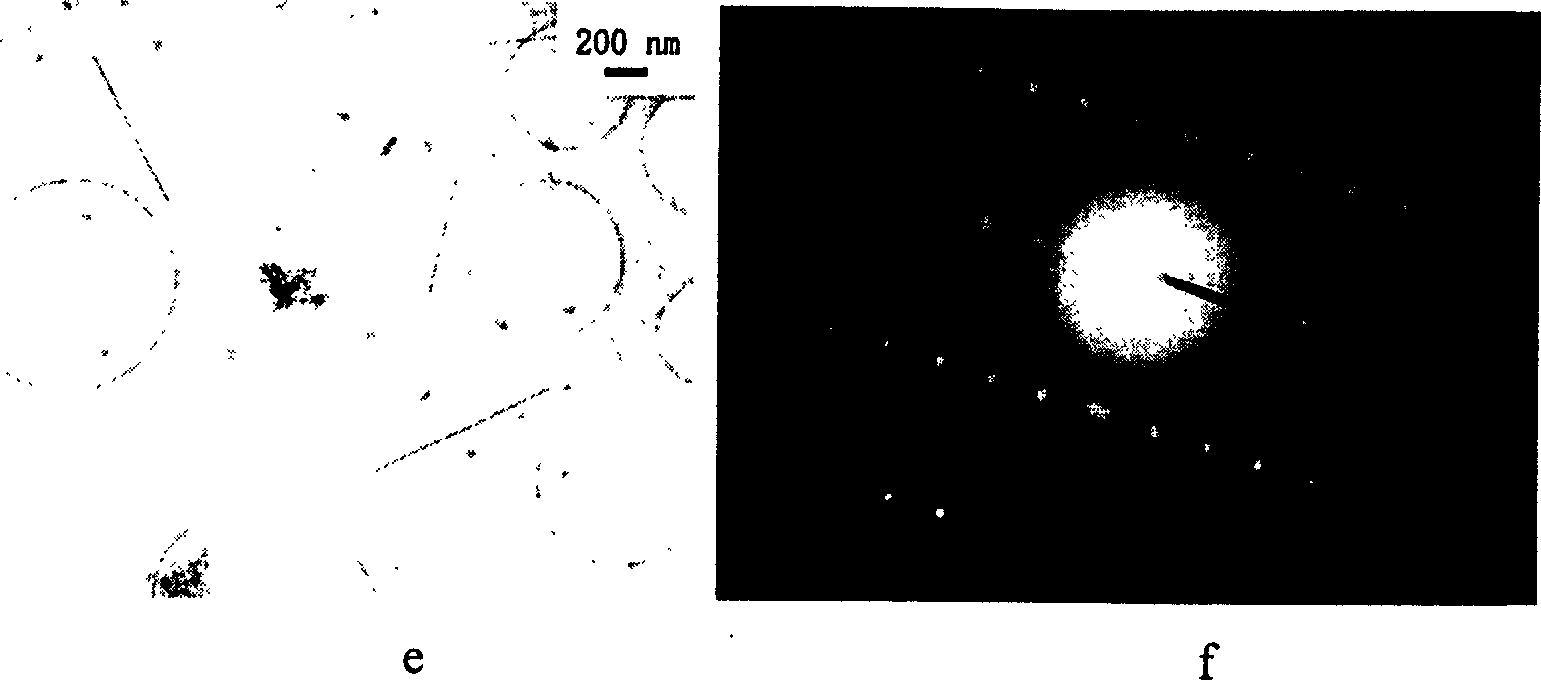

[0016] Add 0.1g of tellurium powder, 1g of NaOH, and 20ml of ethylene glycol into a 100mL round-bottomed flask with a reflux device, heat to boiling with a flame, keep for 2 minutes, cool, and centrifuge the resulting black solid product, and use Distilled water and ethanol were washed several times, and the resulting precipitate was vacuum-dried at room temperature to obtain a black powder of tellurium, 0.094 g, with a yield of 94%. Powder XRD result (see attached figure 1 ) shows that the product is pure hexagonal tellurium. The positions of all peaks matched literature values [Ref: Joint Committee on Powder Diffraction Standards (JCPDS), File No 36-1452.]. No heterogeneous peaks were found, indicating that the purity of the product is relatively high. Photographs by TEM (see attached figure 2 a) It is observed that the tellurium nanocrystals prepared in this way are single cryst...

Embodiment 2

[0017] Example 2. Preparation of one-dimensional nanostructure single crystal tellurium

[0018]Add 0.03g tellurium powder, 2g KOH, and 20 milliliters of ethylene glycol in a 100mL round bottom flask with a reflux device, place this system in a microwave oven (operating frequency 2.45GHz; power is adjusted to 280W) and heat to boiling and Hold for 3 minutes, cool, and the other conditions of preparation are the same as in Example 1, and black powder tellurium is also obtained, 0.028 g, with a yield of 93%. Its powder XRD result and selected area electron diffraction pattern all coincide with the result of embodiment 1, by TEM photo (see attached figure 2 b) It is observed that its crystal form is a single crystal tellurium nanowire or ribbon with a diameter of 40-60 nm and a length of 2-4 μm.

Embodiment 3

[0019] Example 3. Preparation of one-dimensional nanostructure single crystal tellurium

[0020] Change the amount of tellurium powder to 0.05g, the alkali to 2gNaOH, and the solvent to 20ml of glycerin. Put the system in a microwave oven (operating frequency 2.45GHz; power adjusted to 280W) and heat it to 280°C for 3 minutes. Cooling, other conditions of preparation are the same as embodiment 1. Similarly, a one-dimensional nanostructure single crystal tellurium similar to that of Example 1 and Example 2 was also obtained, with a yield of 0.045 g and a yield of 90%. Its powder XRD result and selected area electron diffraction pattern all coincide with the result of embodiment 1, by TEM photo (see attached figure 2 c) It is observed that its crystal form is a single crystal tellurium nanowire or ribbon with a diameter of 20-30 nm and a length of 600-800 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com