Method for using bamboo leaf extract as acrylamide suppressor for heat processing food

A technology of bamboo leaf extract and acrylamide, which is applied in the fields of application, food preservation, and food science, and can solve the problems of no public reports on acrylamide research

- Summary

- Abstract

- Description

- Claims

- Application Information

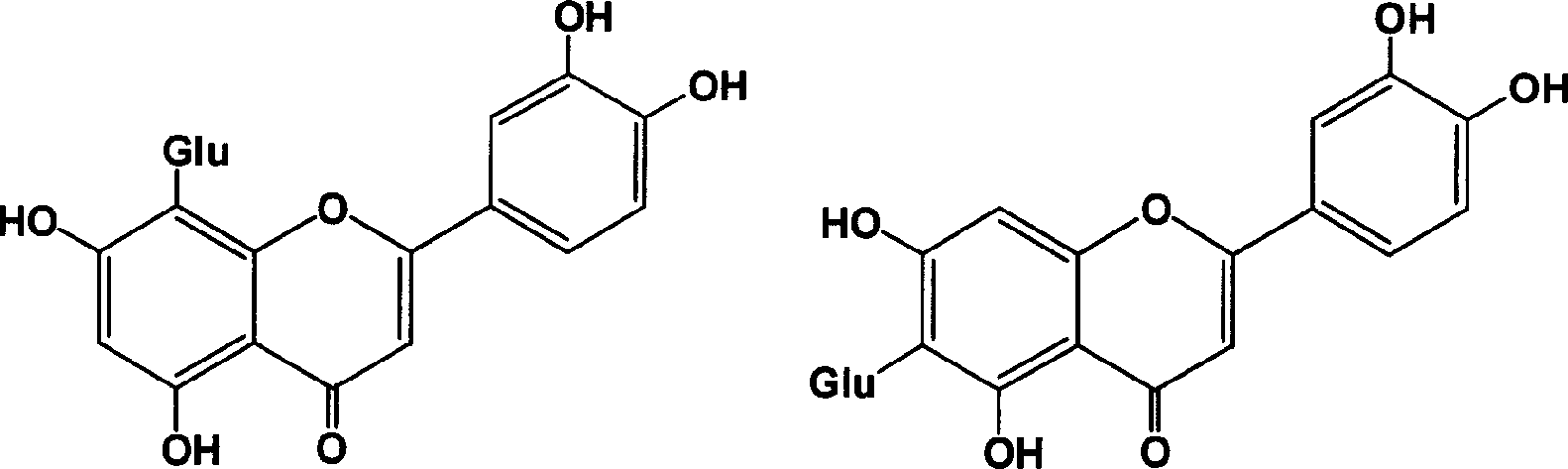

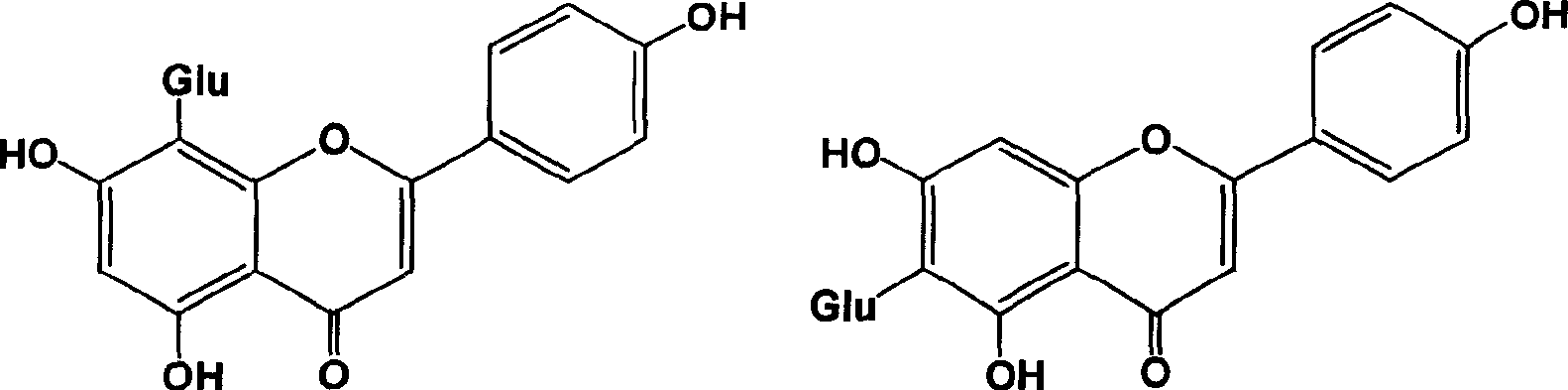

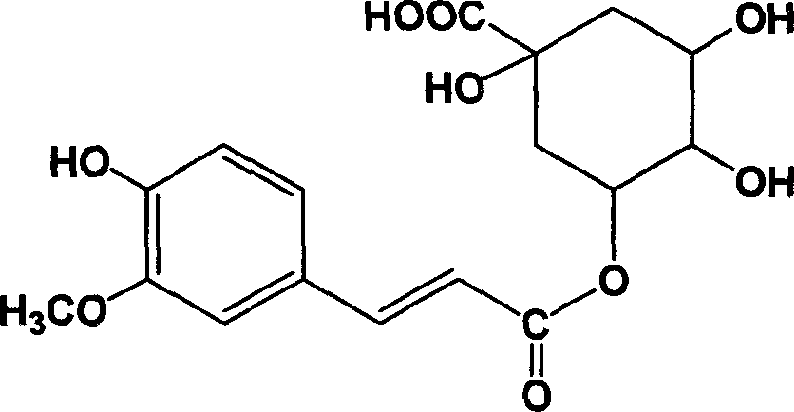

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] Embodiment 1, the compound that contains bamboo leaf extract produces the inhibitory effect of acrylamide on simulated reaction system:

[0059] The bamboo leaf extract, the rosemary extract and the licorice extract are mixed according to a mass ratio of 3:1:1 to obtain a compound, and the bamboo leaf extract accounts for 60% of the total weight of the compound.

[0060] Take 0.1mol / L L-asparagine and D-glucose 10mL each and mix them → put them in a 100mL Erlenmeyer flask → set up a blank control group; add the compound on the basis of the above blank control group to make the final system Test group 1 with compound concentration of 10mg / kg and test group 2 with 150mg / kg respectively → heat the blank control group, test group 1 and test group 2 in a water bath at 120°C for 15 minutes → directly obtain the reaction solution Then derivatization → GC analysis.

[0061] Wherein the specific process of derivatization reaction is as follows:

[0062] Take 20 μL each of the ...

Embodiment 2

[0067] Embodiment 2, the inhibitory effect that the compound containing bamboo leaf extract produces acrylamide to fried potato chips:

[0068] The bamboo leaf extract and the tea extract are mixed according to a mass ratio of 19:1 to obtain a compound, and the bamboo leaf extract accounts for 95% of the total weight of the compound.

[0069] (1) potato chips

[0070] Fresh potatoes are cleaned, peeled and cut into thin slices with a thickness of about 1mm. The cut potato slices are selected, rinsed twice with running water, and dried with absorbent paper.

[0071] (2) Plant extracts

[0072] Bamboo leaf extract: a product produced by Hangzhou Zhedafu Biotechnology Co., Ltd. (the product code is EOB-C01), the total flavonoid content is 40.7%, and the total phenol content is 79.8%;

[0073] Tea extract: a water-soluble tea polyphenol preparation provided by the Tea Science Department of Zhejiang University, with a content of 98%.

[0074] (3) Experimental grouping

[0075] ...

Embodiment 3

[0089] Embodiment 3, the inhibitory effect of the compound containing bamboo leaf extract on producing acrylamide in the process of cigarette burning:

[0090] The bamboo leaf extract, the ginkgo extract and the hawthorn extract are mixed according to a mass ratio of 1:1:1 to obtain a compound, and the bamboo leaf extract accounts for 34% of the total weight of the compound.

[0091] (1) Sample source

[0092] Bamboo leaf extract: the product (product code is EOB-S03) produced by Hangzhou Zhejiang Dalifu Biotechnology Co., Ltd., the appearance is a dark brown concentrated solution, the total flavonoid content is 4.5%, and the solid content is 25.2%; Ginkgo biloba extract and Hawthorn extracts are all commercially available products. In this embodiment, a low-alcohol solution is used as the soaking liquid solvent, which refers to an alcohol solution with a volume fraction of 20%.

[0093] (2) Test groups

[0094] There are 4 groups in this experiment:

[0095] Blank control...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com