Oxygen enriching ion energy-saving device

An energy-saving device and oxygen ion technology, applied in the field of air intake system, can solve the problems of high cost, high combustion temperature of internal combustion engine, complex device, etc., and achieve the effect of low cost and pollution reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described by taking the accompanying drawings as specific embodiments.

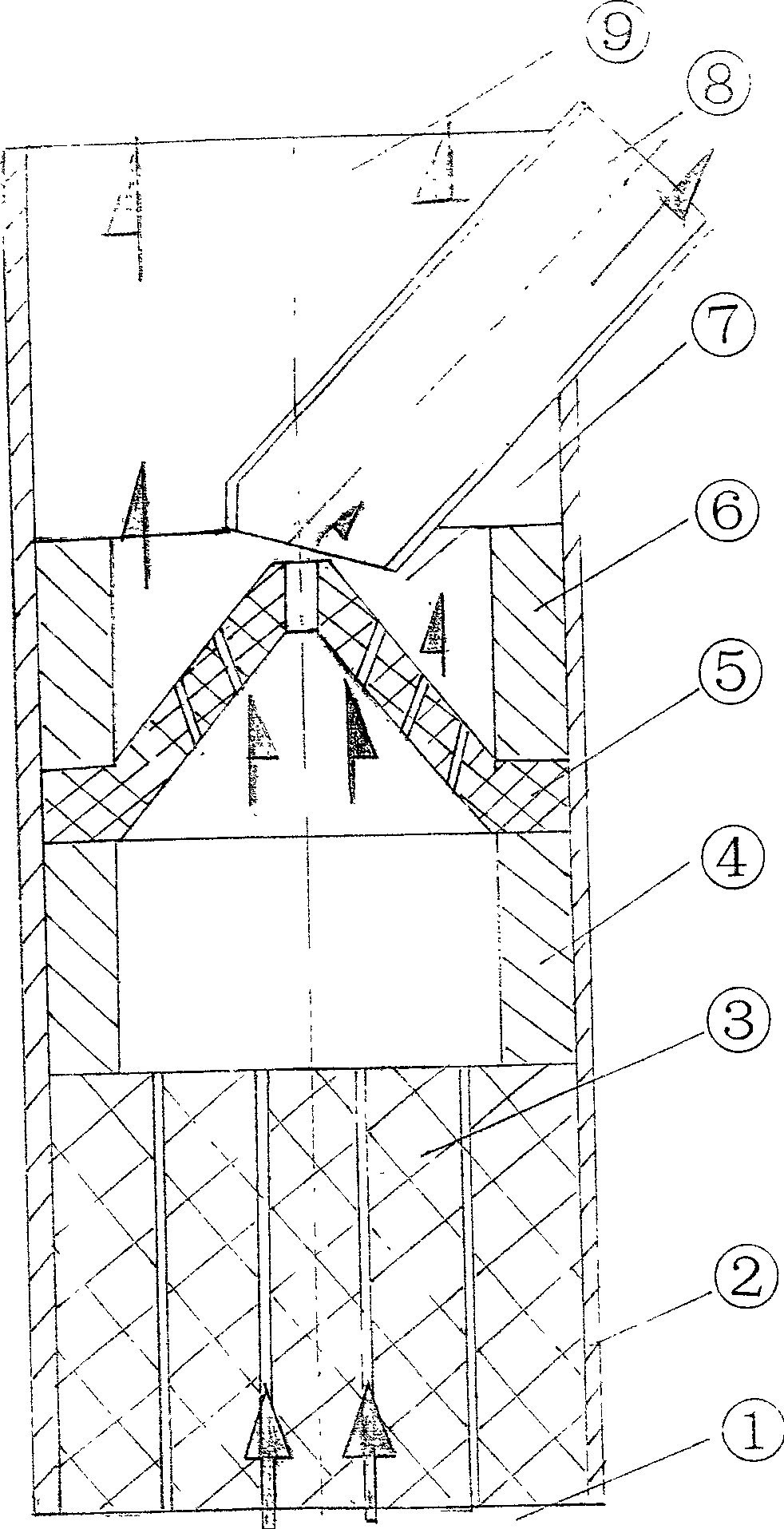

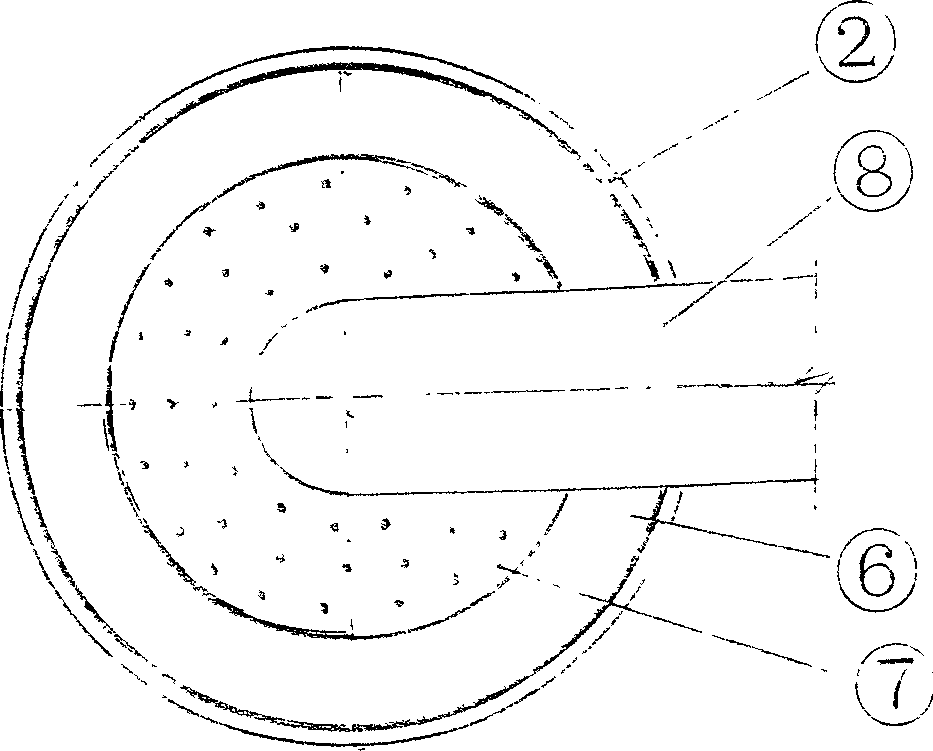

[0023] Oxygen-increasing ion energy-saving device, see figure 1 and 2 . The device includes: air inlet 1 (the lower end of the shell), shell 2, cylindrical porous sintered rare earth 3, cylindrical permanent magnet 4, nitrogen isolation cone 5, cylindrical permanent magnet 6, nitrogen and oxygen ion separation chamber 7, rich Nitrogen air exhaust pipe 8, oxygen-enriched ion air inlet (housing upper end) 9.

[0024] The shell 2 is cylindrical and made of non-magnetic material.

[0025] The cylindrical porous sintered rare earth 3 is a cylinder made of porous sintered rare earth. It is installed inside one end of the housing 2 to form an ionization chamber. Cylindrical porous sintered rare earth 3 contains 1-2% thorium oxide ThO 2 Ceramics fired from low-radioactive rare earth waste slag, the through hole diameter is 1-2 mm, and the hollow rate is 30-50%. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Through hole diameter | aaaaa | aaaaa |

| Magnetic induction | aaaaa | aaaaa |

| Pore diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com