Biphase orthogonal vector control type magnetic stirrer inverter

An electromagnetic stirrer, inverter power supply technology, applied in the direction of AC power input conversion to AC power output, AC power input conversion to DC power output, electrical components and other directions, can solve problems such as powerlessness, achieve high voltage utilization, control Convenience, effect on load capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

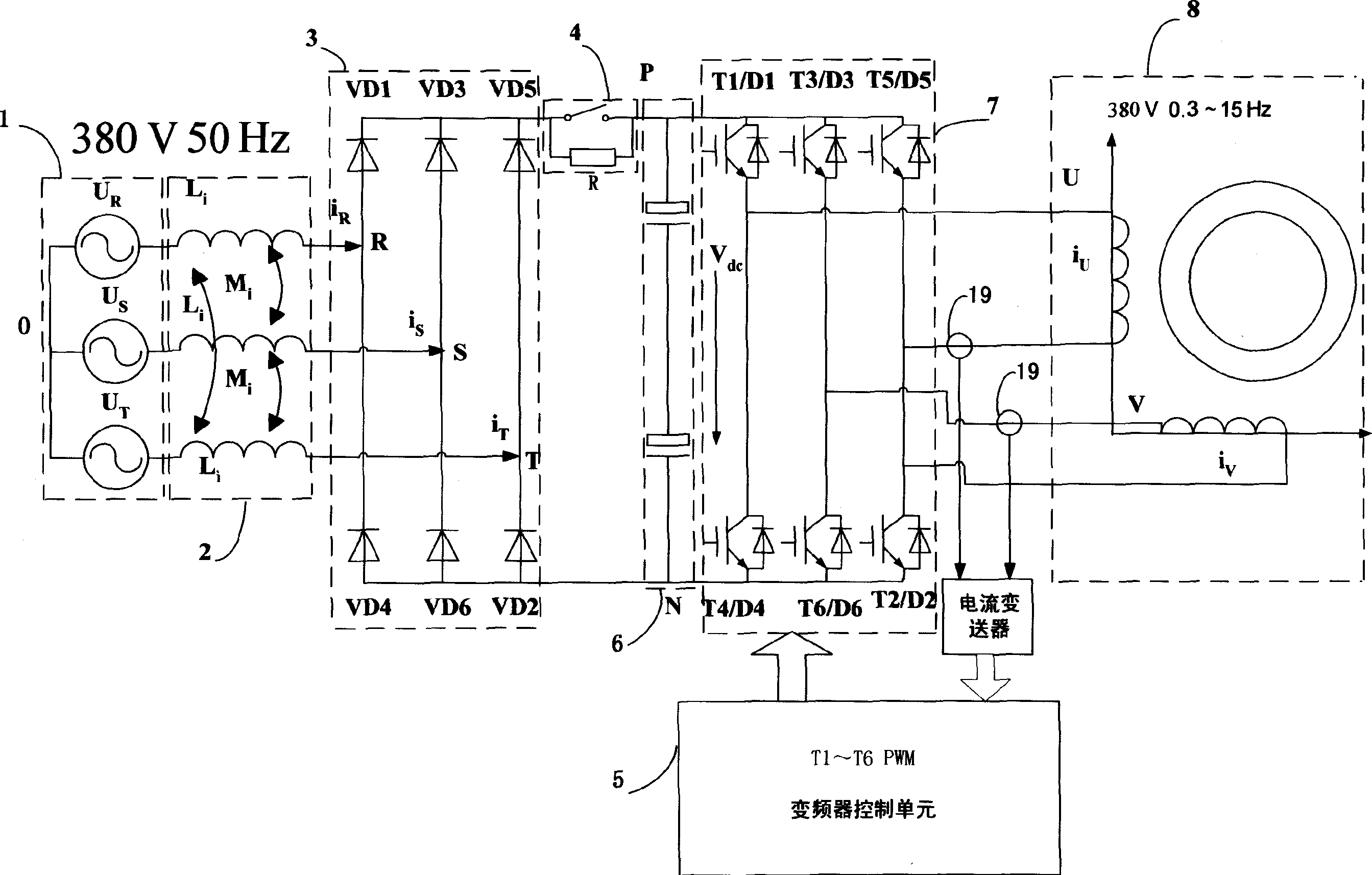

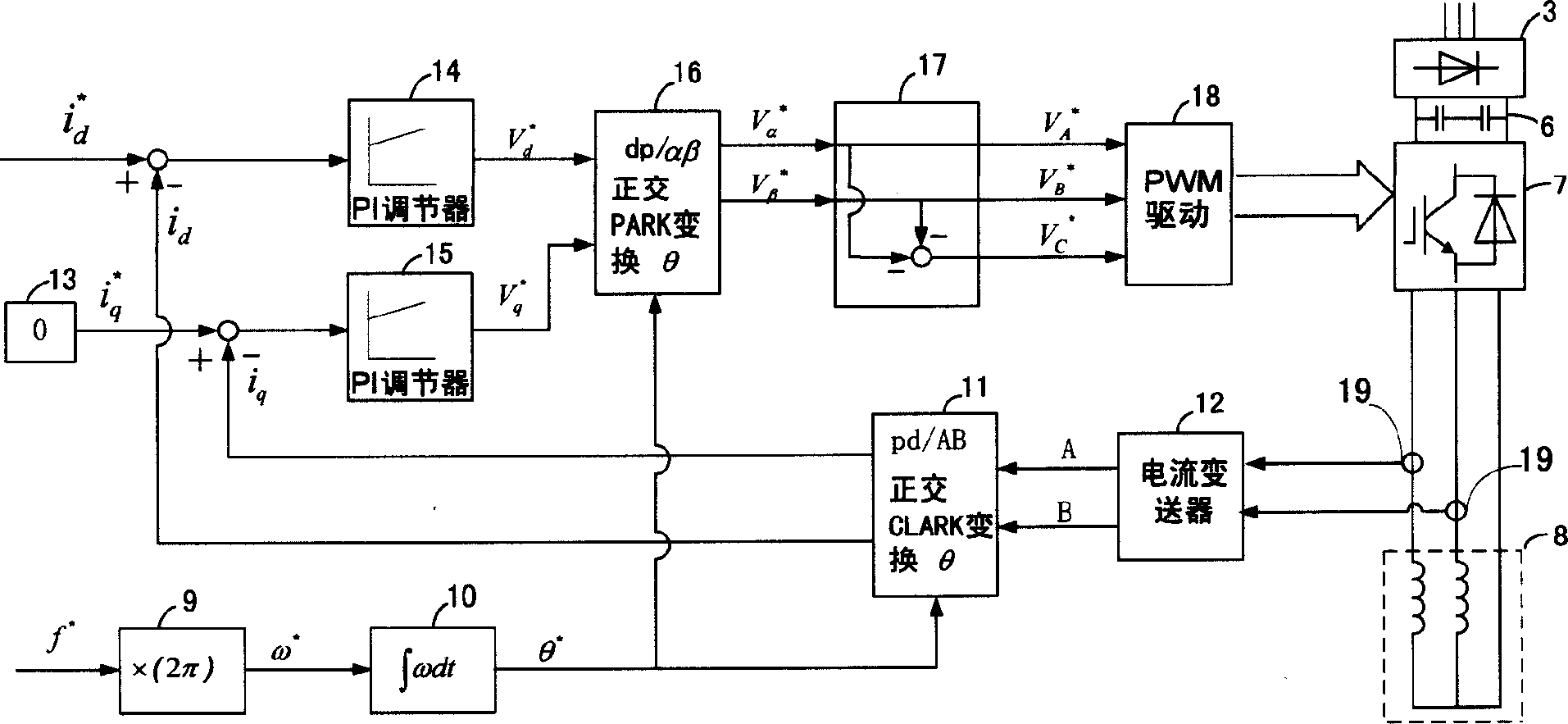

[0022] See attached figure 2 It is a simulation system diagram of an embodiment of the present invention, and the embodiment of the present invention is a two-phase electromagnetic stirrer system. by figure 2 Example combination figure 1 Embodiments of the present invention will be described.

[0023] figure 1 It is the main circuit diagram of the two-phase electromagnetic stirrer according to the preferred embodiment of the present invention. The AC current enters the diode rectifier circuit 3 through the smoothing reactor 2 to provide DC power for the subsequent voltage source controllable inverter circuit. When the system is working, the switch k is turned off, and the current passes through the resistor R to charge the capacitor bank 6 . R plays the role of overcurrent protection for the capacitor. When entering steady state, k is closed and full current supplies power to capacitor bank 6.

[0024]Circuit 7 is the inverter part composed of IGBT. The connection meth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com