Method for refining catalytic gasoline

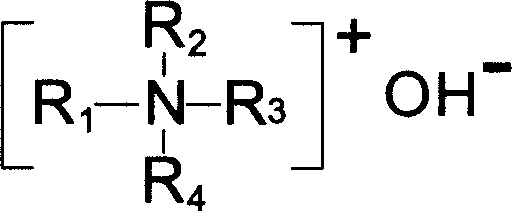

A technology of catalytic cracking gasoline and a refining method, which is applied in the field of refining catalytic cracking gasoline to remove hydrogen sulfide and mercaptan sulfur, and can solve the problems of undisclosed activator active components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

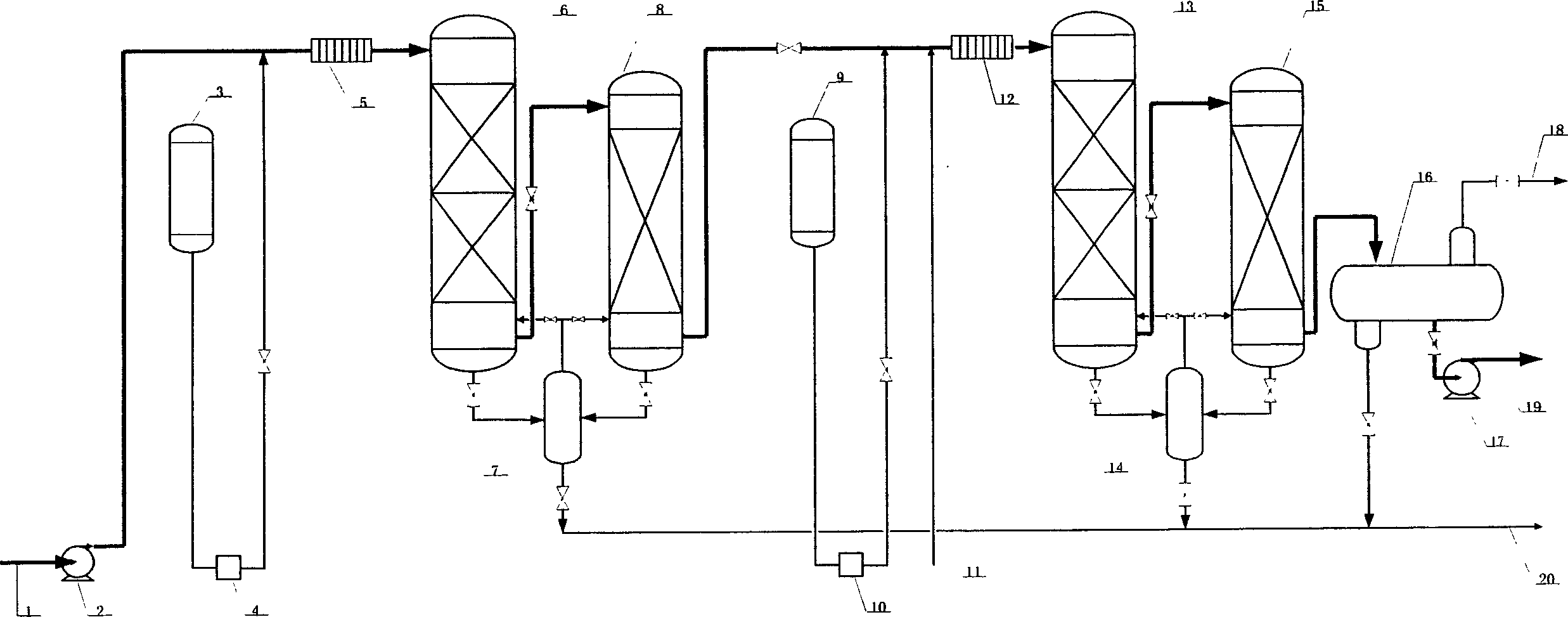

Method used

Image

Examples

Embodiment 1

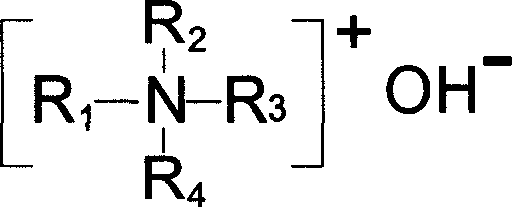

[0069] FCC gasoline feed containing hydrogen sulfide sulfur 15ppm and mercaptan sulfur 57ppm is mixed with 10ppm activator, the activator is tetraethylammonium hydroxide, and the mixture is passed through the solid adsorbent equipped with activated carbon of 10wt% basic copper carbonate In the hydrogen sulfide removal tower, the temperature is 30°C, the pressure is 0.3MPa, and the volume space velocity is 1h -1 , and then through the sand filter tower to remove a small amount of mechanical impurities and waste liquid, after the dehydrogen sulfide tower and sand filter tower, the catalytic cracked gasoline has a hydrogen sulfide content of 0ppm, and then mixes it with 8ppm of co-catalyst and air, and the co-catalyst is hydrogen oxidation Trimethyl dodecyl ammonium, the air addition rate is 25ml / min, and the mixture is passed through the mercaptan oxidation tower of the sweetening catalyst of the active carbon of loading 0.1wt% cobalt phthalocyanine, in the mercaptan oxidation to...

Embodiment 2

[0071] The catalytic cracking gasoline feed containing hydrogen sulfide sulfur 15ppm, mercaptan sulfur 57ppm is mixed with 12ppm of activator, and activator is tetrapropylammonium hydroxide, and the mixture is passed through the solid adsorbent that is equipped with the activated carbon of 13wt% zinc carbonate Dehydrogen sulfide tower, in the dehydrogen sulfide tower, the temperature is 25°C, the pressure is 0.25MPa, and the volume space velocity is 1.5h -1 , and then through the sand filter tower to remove a small amount of mechanical impurities and waste liquid, after the dehydrogen sulfide tower and sand filter tower, the catalytic cracked gasoline has a hydrogen sulfide content of 0ppm, and then mixes it with 15ppm of co-catalyst and air, and the co-catalyst is hydrogen oxidation Trimethyltetradecylammonium, the air addition is 25ml / min, and the mixture is passed through the mercaptan oxidation tower of the sweetening catalyst of the activated carbon of 0.15wt% sulfonated p...

Embodiment 3

[0073] The catalytic cracking gasoline feed containing hydrogen sulfide sulfur 15ppm, mercaptan sulfur 57ppm is mixed with 15ppm of activator, and activator is tetrabutylammonium hydroxide, and mixture is passed through the solid adsorbent of the activated carbon of loading 18wt% sodium carbonate Dehydrogen sulfide tower, in the dehydrogen sulfide tower, the temperature is 35°C, the pressure is 0.33MPa, and the volume space velocity is 1.2h -1 , and then through the sand filter tower to remove a small amount of mechanical impurities and waste liquid, the hydrogen sulfide content of catalytically cracked gasoline after the dehydrogen sulfide tower and sand filter tower is 0ppm, and then mixed with 12ppm co-catalyst and air, the co-catalyst is hydrogen oxidation Trimethyl cetyl ammonium, the air addition is 25ml / min, and the mixture is passed through the mercaptan oxidation tower of the sweetening catalyst of the active carbon of loading 0.25wt% polyphthalocyanine cobalt, and in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com