Side surface pumped thin disk laser and method for making same

A thin-sheet laser and side-pumped technology, which is applied in lasers, laser components, phonon exciters, etc., can solve the problems of low edge pumping efficiency and low laser efficiency, and achieve simple structure, low cost, and mechanical stability Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

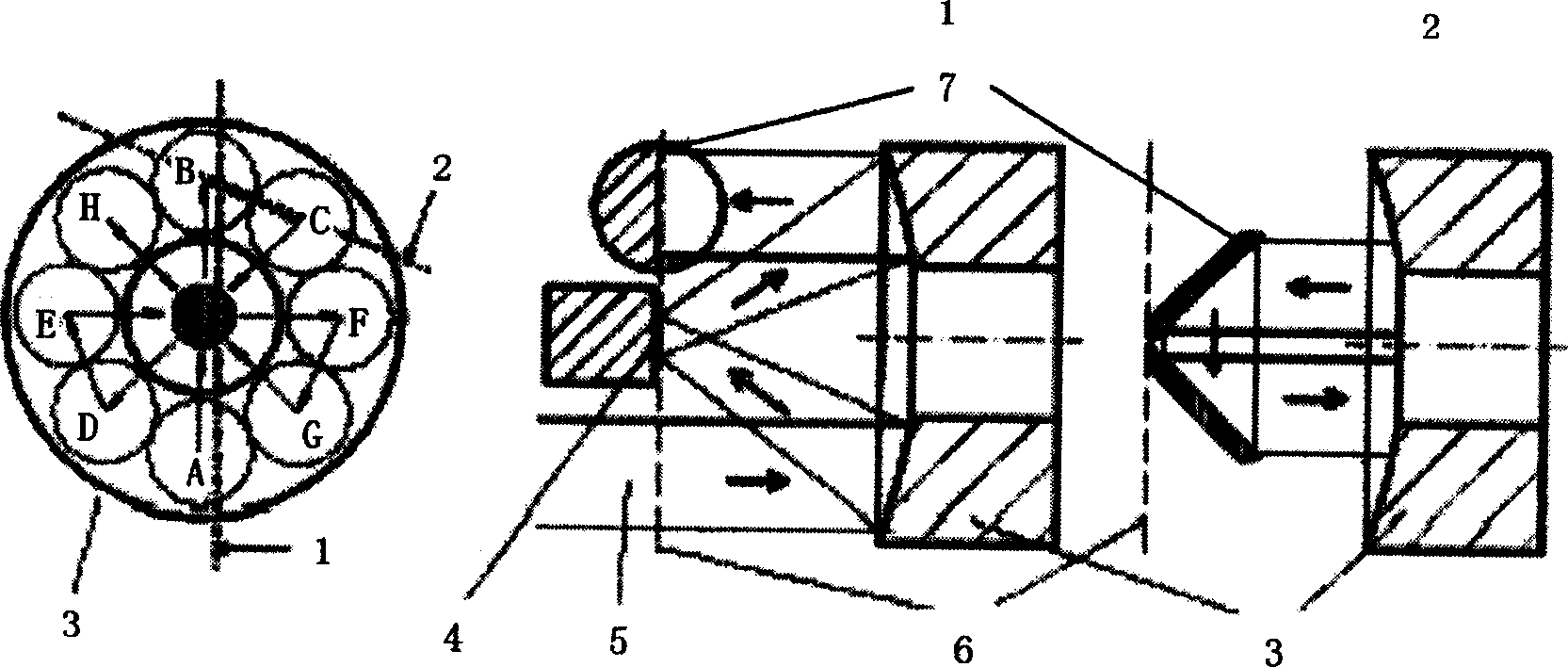

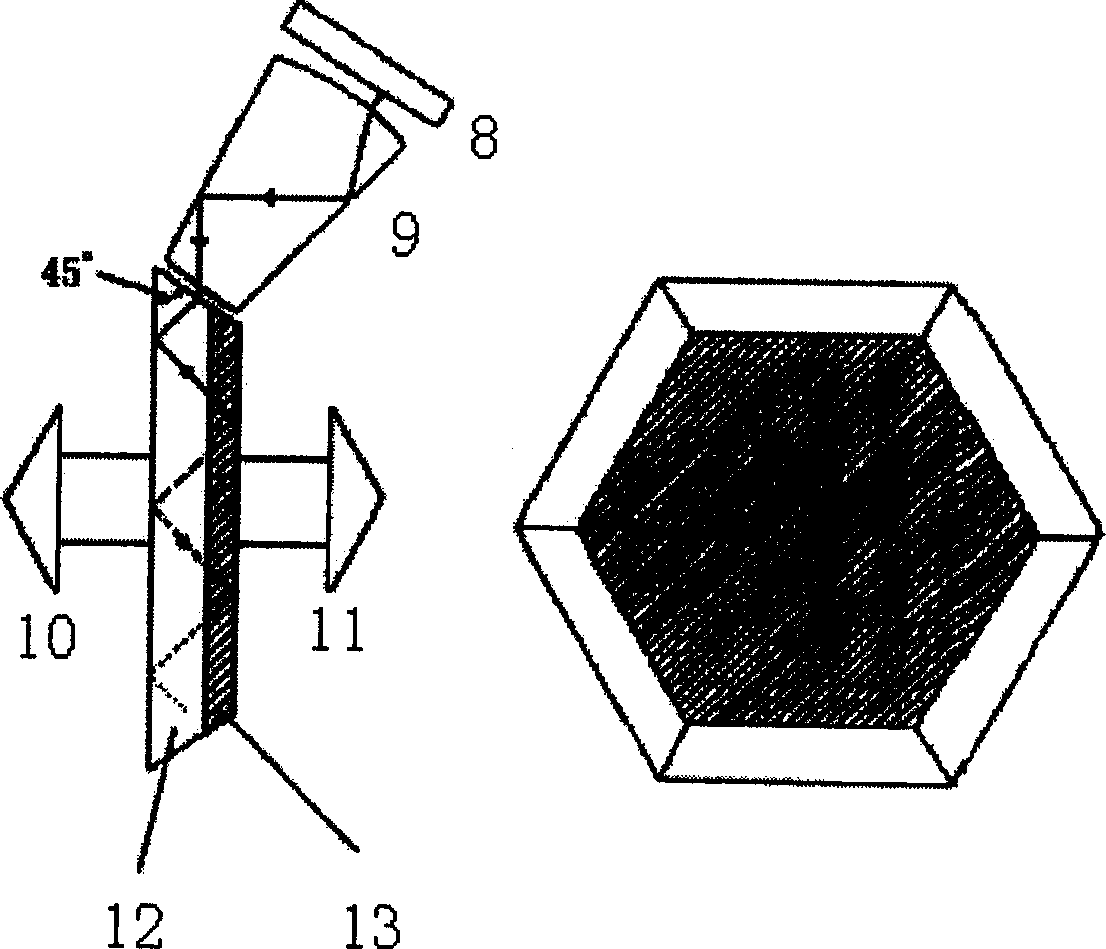

Method used

Image

Examples

Embodiment Construction

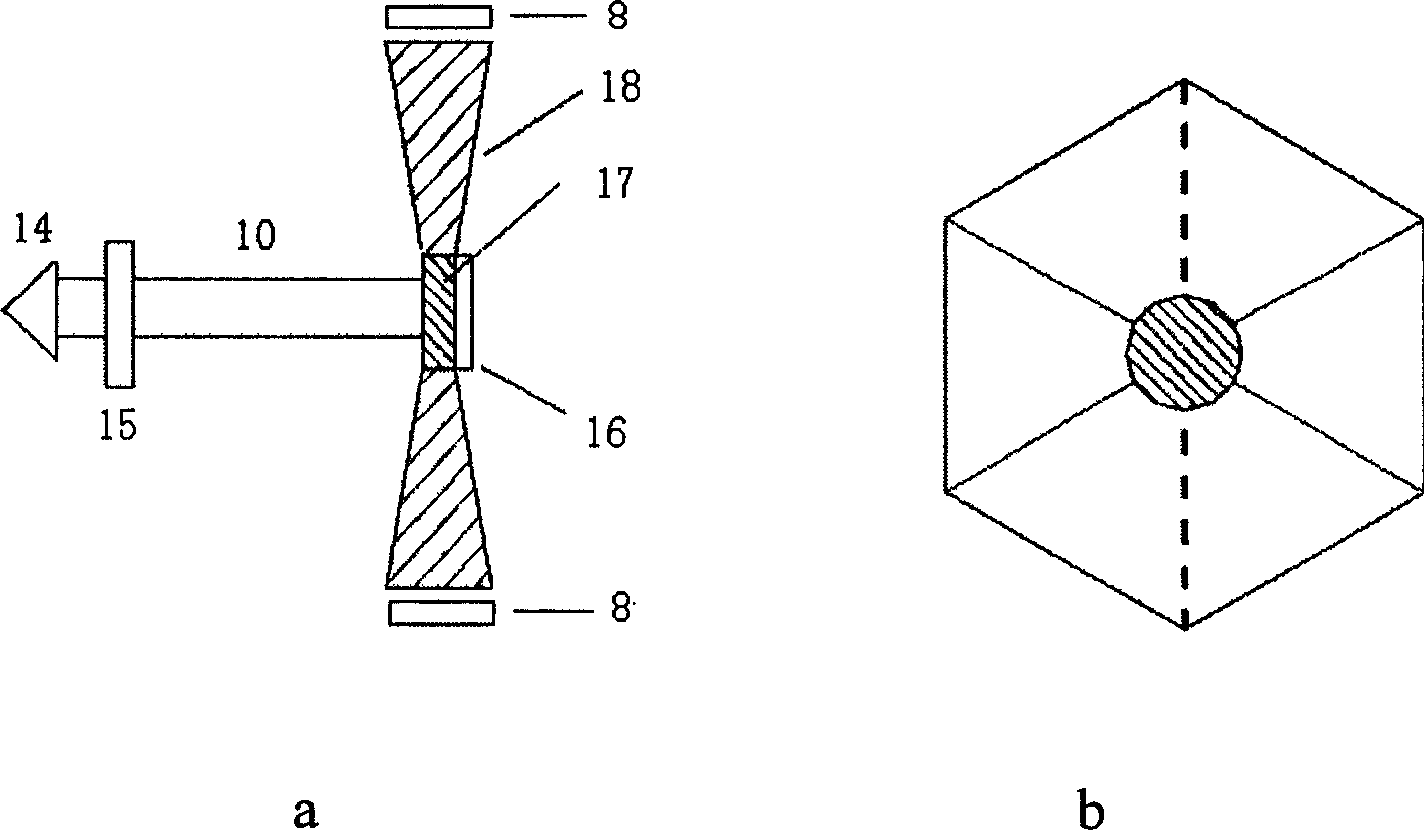

[0038] The design drawing of the present invention is as follows image 3 shown. The center is a doped gain medium circular thin crystal, the outside is a regular hexagonal non-doped irregular structure crystal, there is a cylindrical hole in the center, the outer regular hexagon is thick, and the middle cylindrical hole is thin, and its symmetrical section is a symmetrical isosceles trapezoid. Yb:YAG crystal is selected as the cylindrical flake crystal of doped gain medium. YAG is selected for the undoped irregular structure crystal. The doped gain medium wafer crystal (with a doping concentration of 3 at%) and the undoped irregular structure crystal are tightly bonded by thermal bonding.

[0039] The preparation method of the doped gain medium wafer crystal and the non-doped irregular structure crystal is as follows: the first step, the two bottom surfaces (thickness 1.0mm) of the doped gain medium wafer crystal and the side surface (diameter 5mm positive) of the wafer cry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com