Catalyst for producing cycloolefine by partial hydrogenation of mononuclear aromatics, and its preparing method and use

A single-ring aromatic hydrocarbon and catalyst technology, applied in the field of catalysts, can solve problems affecting the stable operation of production equipment, affecting catalyst selectivity, and inability to maximize profits, and achieve the effects of reducing sensitivity, simple adjustment, and thorough reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1, catalyst preparation: the RuCl of 44.8 grams 3 .3H 2 O and 6.3 g of ZnCl 2 and 1.0 g of H 2 PtCL 6 ·6H 2 Pour O into 600ml of water and stir to dissolve it. 150 ml of 30% aqueous sodium hydroxide solution were added dropwise, and the mixture was stirred at a temperature of 80°C for a further 2 hours. Inject into an autoclave (volume 1000ml) coated with Teflon on the inner surface, fill the kettle with hydrogen, thereby increasing the total pressure in the kettle to 50kg / cm 2 G, reduction at 150°C for 6 hours under high-speed stirring. The reaction mixture was cooled, then washed with water, and then dried in vacuo to obtain 19.8 g of a hydrogenation catalyst. The average crystallite diameter of the catalyst was analyzed by X-ray diffractometer to be 52 Å.

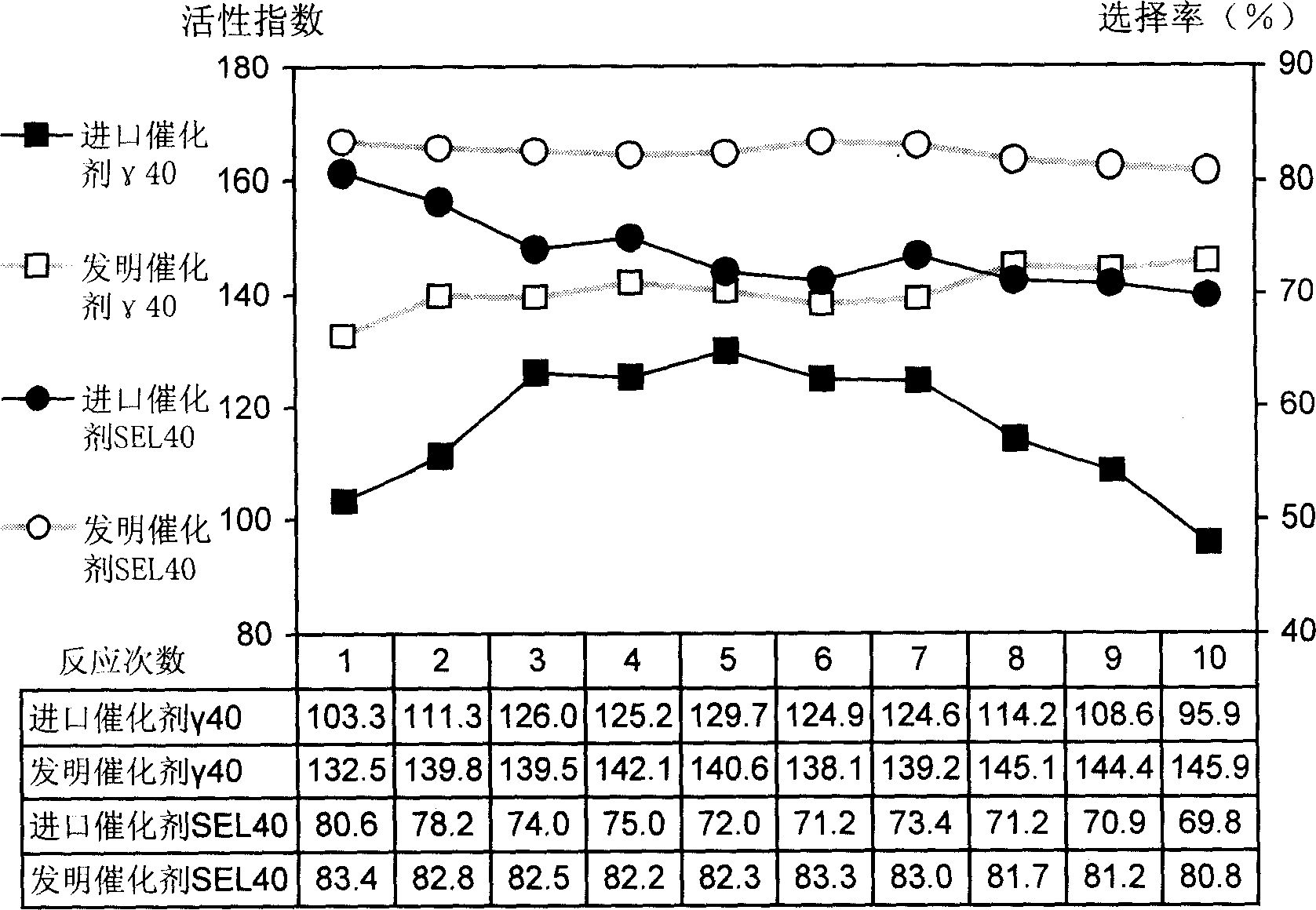

[0026] Catalyst application evaluation: Weigh 1.2 grams of the catalyst, 250ml of water, 50 grams of ZnSO 4 ·7H 2 O, 9.8 g ZrO 2 Put it into an autoclave (internal volume is 1000ml) coated wi...

Embodiment 2

[0027] Embodiment 2, catalyst preparation: the RuCl of 13.3 grams 3 .3H 2 O and 1.7 g of ZnCl 2 and 0.6 g of H 2 PtCL 6 ·6H2 O was poured into 400ml of water and stirred to dissolve it, and 45ml of 30% sodium hydroxide aqueous solution was added dropwise, and the operation was prepared according to Example 1 to obtain 5.83 grams of hydrogenation catalyst. The average crystallite diameter of the catalyst analyzed by X-ray diffractometer was 75 Å.

[0028] Take by weighing 1.9 grams of this catalyst and evaluate the operation according to Example 1, and its performance evaluation results are shown in Table 1.

Embodiment 3

[0029] Embodiment 3, catalyst preparation: the RuCl of 8.8 grams 3 .3H 2 O and 0.7 g of ZnCl 2 and 0.62 g of H 2 PtCL 6 ·6H 2 O was poured into 400ml of water and stirred to dissolve it, and 25ml of 30% sodium hydroxide aqueous solution was added dropwise, and the preparation operation was carried out according to Example 1 to obtain 3.6 grams of hydrogenation catalyst. The average crystallite diameter of the catalyst analyzed by X-ray diffractometer was 93 Å. Weigh 1.0 gram of this catalyst and evaluate the operation according to Example 1, and its performance evaluation results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com