Method for preparing phosphate positive-pole material of lithium-ion cell

A lithium-ion battery and cathode material technology, applied in the field of battery cathode material preparation, can solve the problems of harsh process requirements, difficult to obtain results, reduce the actual capacity of materials, etc., and achieve the effect of simple process conditions and high actual capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] LiF, FeC 2 o 4 2H 2 O and NH 4 h 2 PO 4 Take by weighing according to the stoichiometric ratio of Li:Fe:P=1:1:1, grind in an agate mortar for 30min, and mix well;

[0033] Then carry out pretreatment under argon protection at 200°C for 24 hours, and then grind after natural cooling;

[0034] Finally, under argon protection, sintering at 700°C for 24 hours, and cooling naturally, the phosphate cathode material LiFePO for lithium-ion batteries was obtained. 4 .

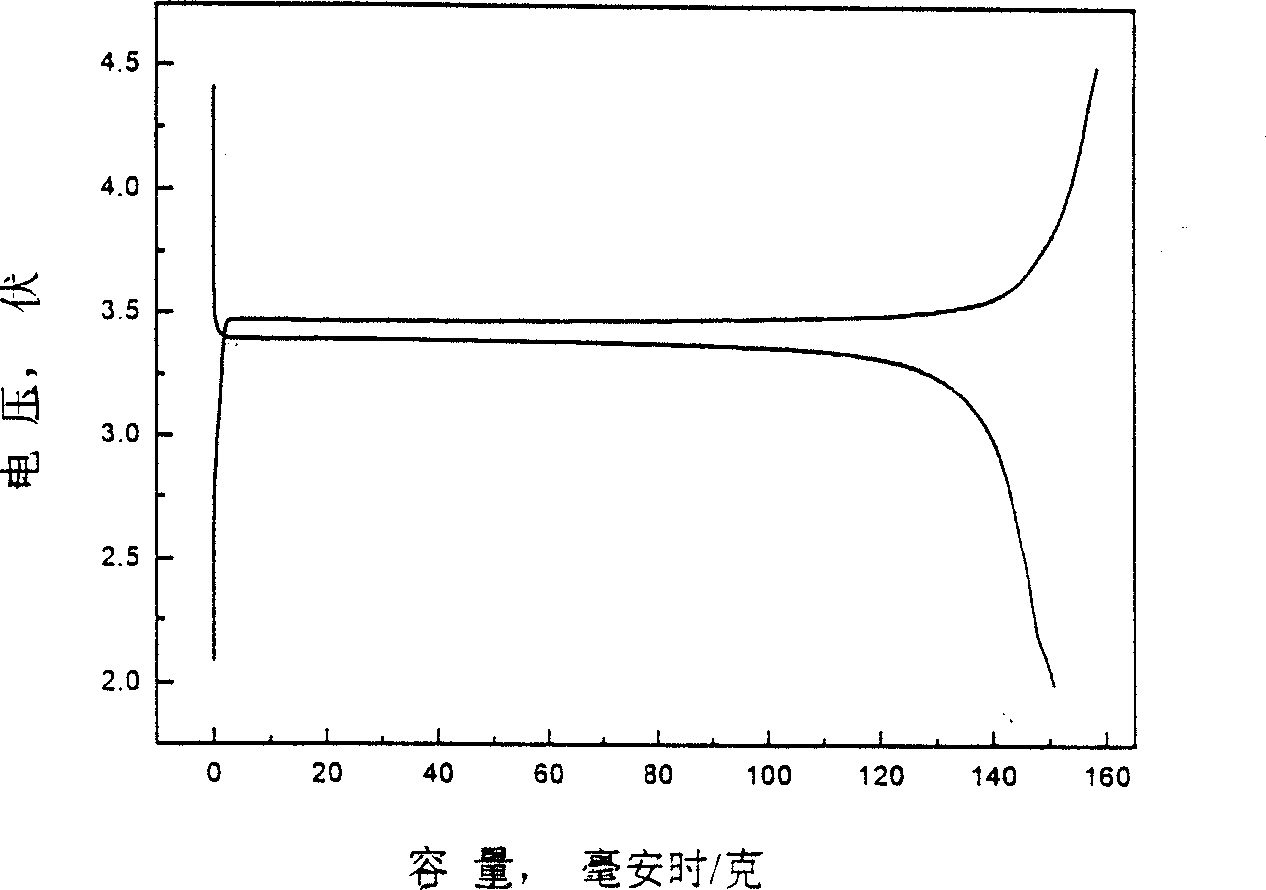

[0035] The LiFePO 4 The charge and discharge curve of the first 2 weeks see figure 1 , for circularity see Figure 6 , The charge and discharge current is 10mA / g.

Embodiment 2

[0037] LiF, FeC 2 o 4 2H 2 O and (NH 4 ) 2 HPO 4 According to the stoichiometric ratio of Li:Fe:P=1:1:1, each mole of LiFePO 4 Add 26g of sucrose and mix the mixture evenly;

[0038] Then carry out pretreatment under argon protection at 400°C for 8 hours, and then grind after natural cooling;

[0039] Finally, under argon protection, sintering at 700°C for 24 hours, and cooling naturally, the carbon-coated lithium-ion battery phosphate cathode material LiFePO was obtained. 4 .

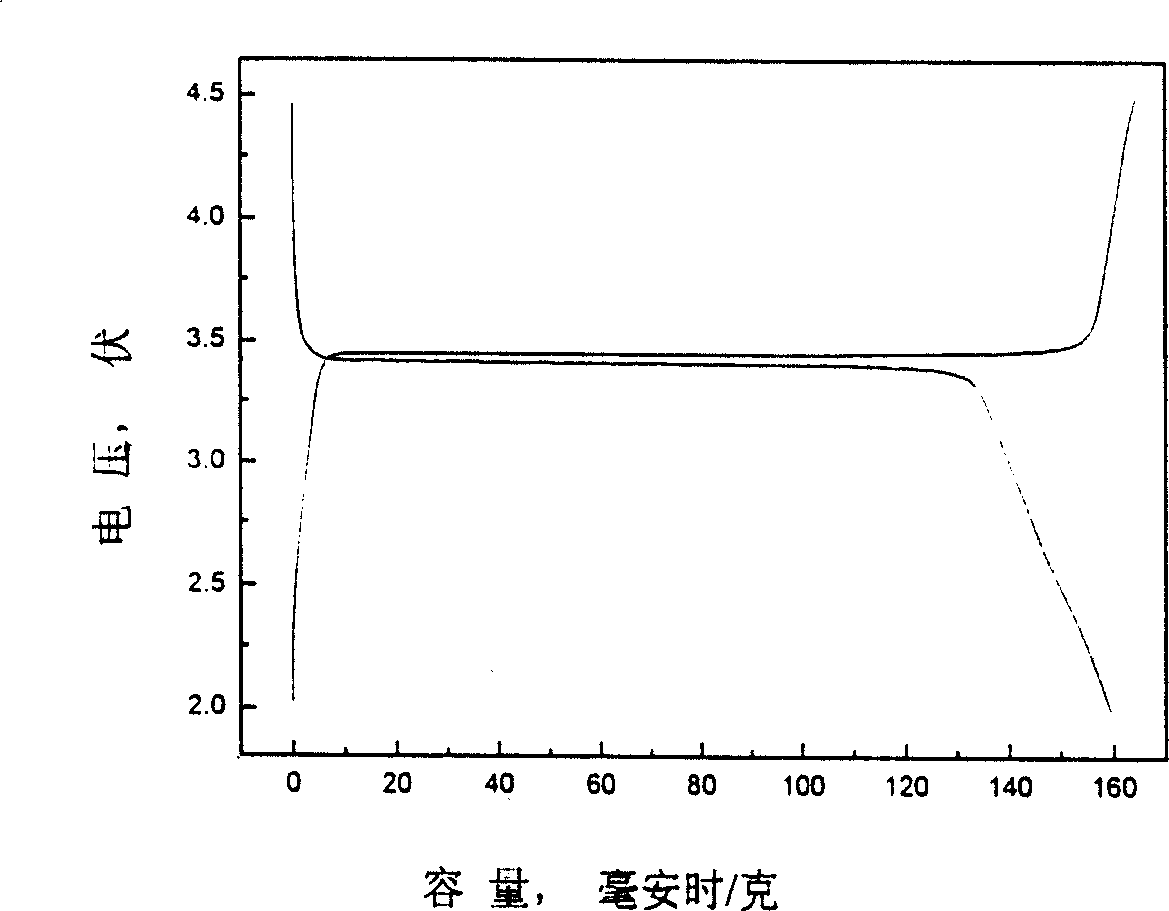

[0040] The carbon coated LiFePO 4 The charge-discharge curve of the 20th week see figure 2 , for circularity see Figure 6 , The charge and discharge current is 10mA / g.

Embodiment 3

[0042] LiF, Fe 3 (PO 4 ) 2 ·5H 2 O and (NH 4 ) 3 PO 4 Take by weighing according to the stoichiometric ratio of Li:Fe:P=1:1:1, grind in an agate mortar for 30min, and mix well;

[0043] Then carry out pretreatment under argon protection at 500°C for 0.5h, and then grind after natural cooling;

[0044] Finally, under argon protection, sintering at 600 °C for 48 hours, and natural cooling, the phosphate cathode material LiFePO for lithium-ion batteries was obtained. 4 .

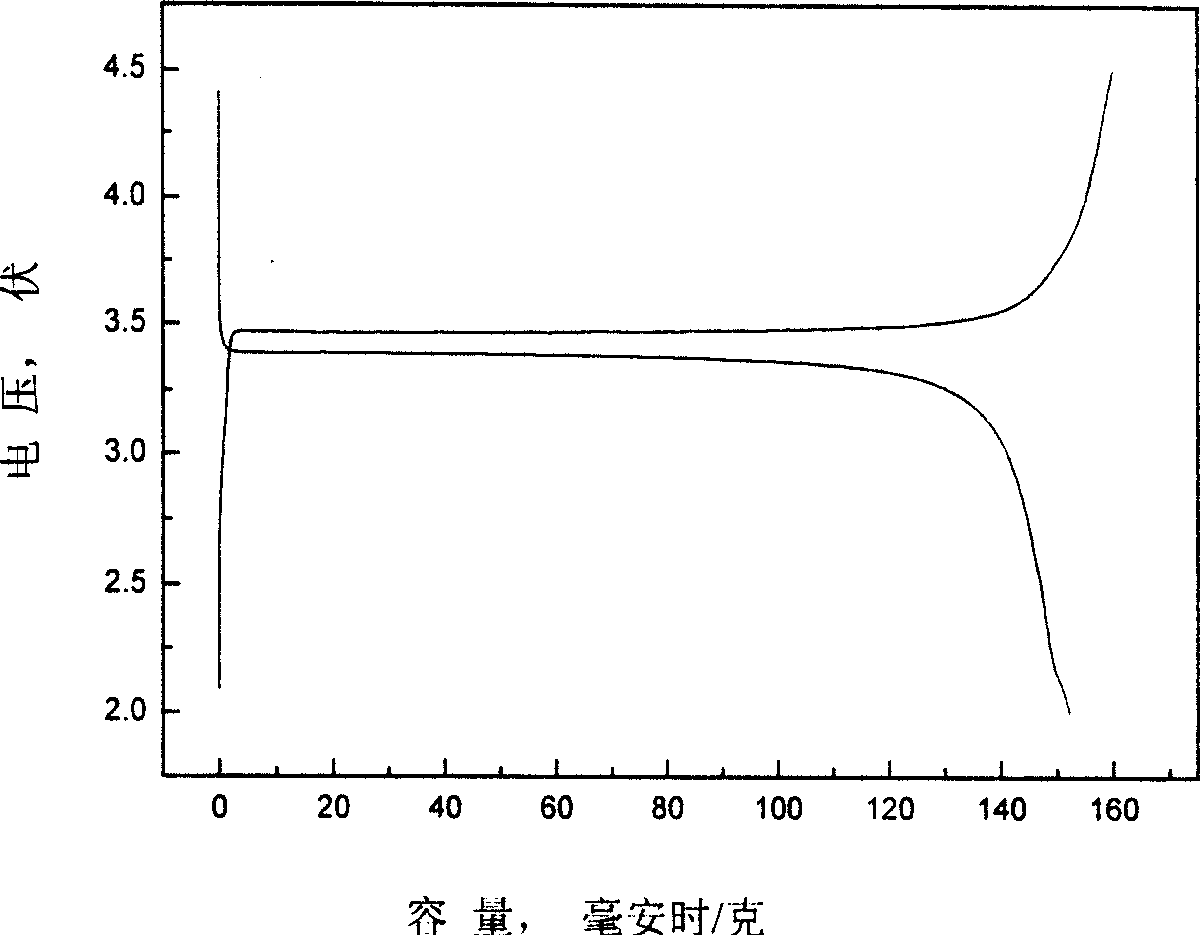

[0045] The LiFePO 4 The charge and discharge curve of the first 2 weeks see image 3 , for circularity see Figure 6 , The charge and discharge current is 10mA / g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com