Method for producing nano material of alpha-Fe00H and alpha Fe2O3 in one dimension

A nanomaterial and production method technology, applied in the directions of iron oxide/iron hydroxide, iron oxide, etc., can solve the problems of difficulty in realizing large-scale industrial production, complicated operation steps, high cost, and achieve high yield, low cost, simple craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

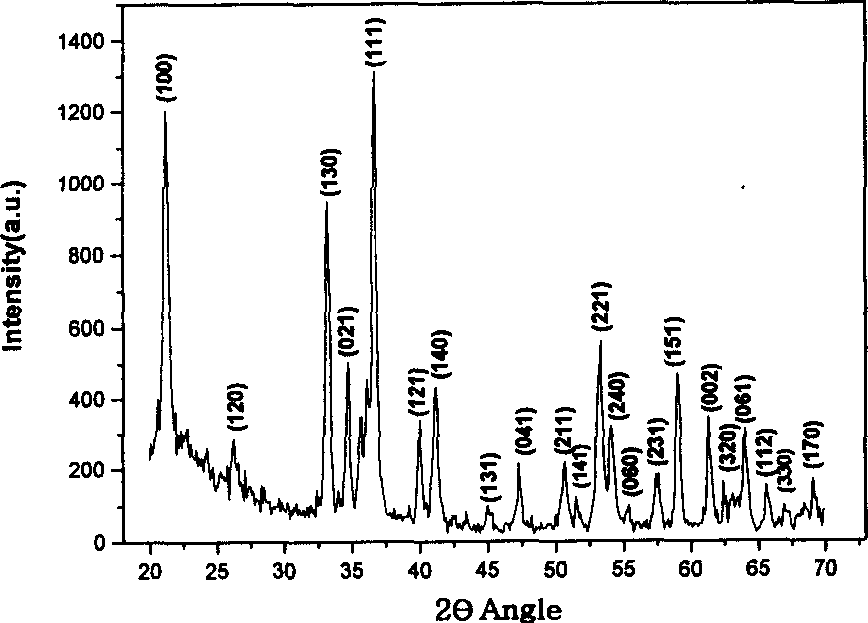

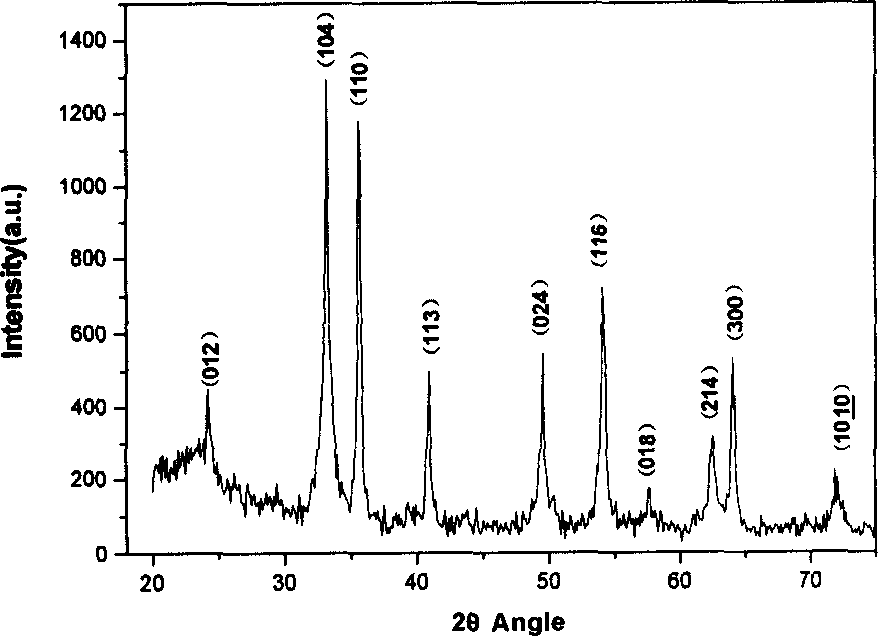

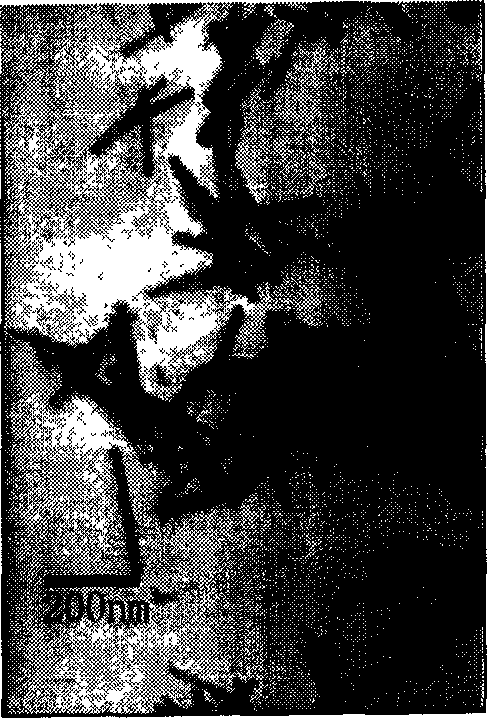

[0019] Weigh 0.0005mol of ferrous sulfate and 0.001mol of anhydrous sodium acetate and add 20ml of water to dissolve, electromagnetically stir in the air for 20min, transfer to a 20ml stainless steel reaction kettle, conduct a hydrothermal reaction at 110°C for 8 hours, and then cool the completely reacted product to room temperature, and finally washed with deionized water and vacuum-dried to obtain the product α-FeOOH nanorods. The obtained α-FeOOH nanorods were calcined in a muffle furnace at 240 °C for 2 hours to obtain α-Fe 2 o 3 Nano stave.

Embodiment 2

[0021] Weigh 0.0005mol ferrous chloride and 0.001mol anhydrous sodium acetate, add 20ml water to dissolve, electromagnetically stir in the air for 5min, transfer to a 20ml stainless steel reaction kettle, react hydrothermally at 80°C for 5 hours, and then cool the completely reacted product to room temperature, and finally washed with deionized water and vacuum-dried to obtain the product α-FeOOH nanorods. The obtained α-FeOOH nanorods were calcined in a muffle furnace at 300 °C for 1.5 hours to obtain α-Fe 2 o 3 Nano stave.

Embodiment 3

[0023] Weigh 0.001mol of ferrous sulfate and 0.002mol of anhydrous potassium acetate and add 20ml of water to dissolve, electromagnetically stir in the air for 30min, transfer to a 20ml stainless steel reaction kettle, conduct a hydrothermal reaction at 60°C for 12 hours, then cool the completely reacted product to room temperature, and finally washed with deionized water and vacuum-dried to obtain α-FeOOH nanorods. The obtained α-FeOOH nanorods were calcined in a muffle furnace at 360 °C for 1.5 hours to obtain α-Fe 2 o 3 Nano stave.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com