Method for preparing butanedione through oxidating acetylmethylcarbinol

A technology of acetoin and diacetyl, applied in the field of oxidation of acetoin to diacetyl, can solve the problems of high production cost, rare raw materials, difficult purification of products, etc., and achieve low production cost, simple operation and high selectivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

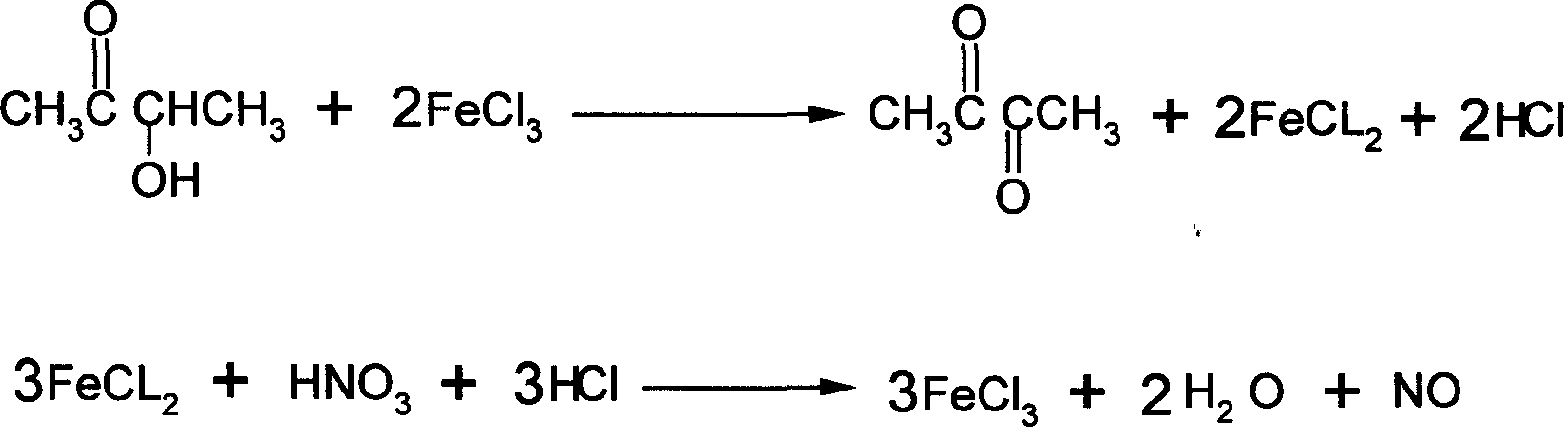

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described in detail below in combination with the technical scheme and the best embodiment.

[0013] Add 220 g (2.5 mol) of acetoin, 500 ml of water and 1360 g of hexahydrate crystalline ferric chloride (5.0 mol) in a 3-liter three-necked flask equipped with mechanical stirring, dropping funnel, fractionating column and condenser. The mixture was heated to 100°C, and diacetyl was collected until there was no distillate. The water layer of the distillate was removed, and the oil layer was dried with calcium chloride and rectified to obtain 161 grams of diacetyl. The purity of the product is not less than 99%, the refractive index is 1.3935, the boiling point is 88.0-88.5°C, and the yield is 75%.

[0014] Pour the still liquid ferrous chloride into the filter tank to filter. The sieve plate in the middle of the filter tank must be paved with small stones and sand, and then covered with filter cloth. The bottom of the tank should be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com