Vacuum recrystallization method for purifying metallic antimony and equipment thereof

A technology of vacuum rectification and purification method, which is applied in the direction of improving process efficiency, etc., and can solve problems such as secondary pollution and complex purification of antimony metal, and achieve the effects of improving recovery rate, simple and reasonable structure, and solving technical problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

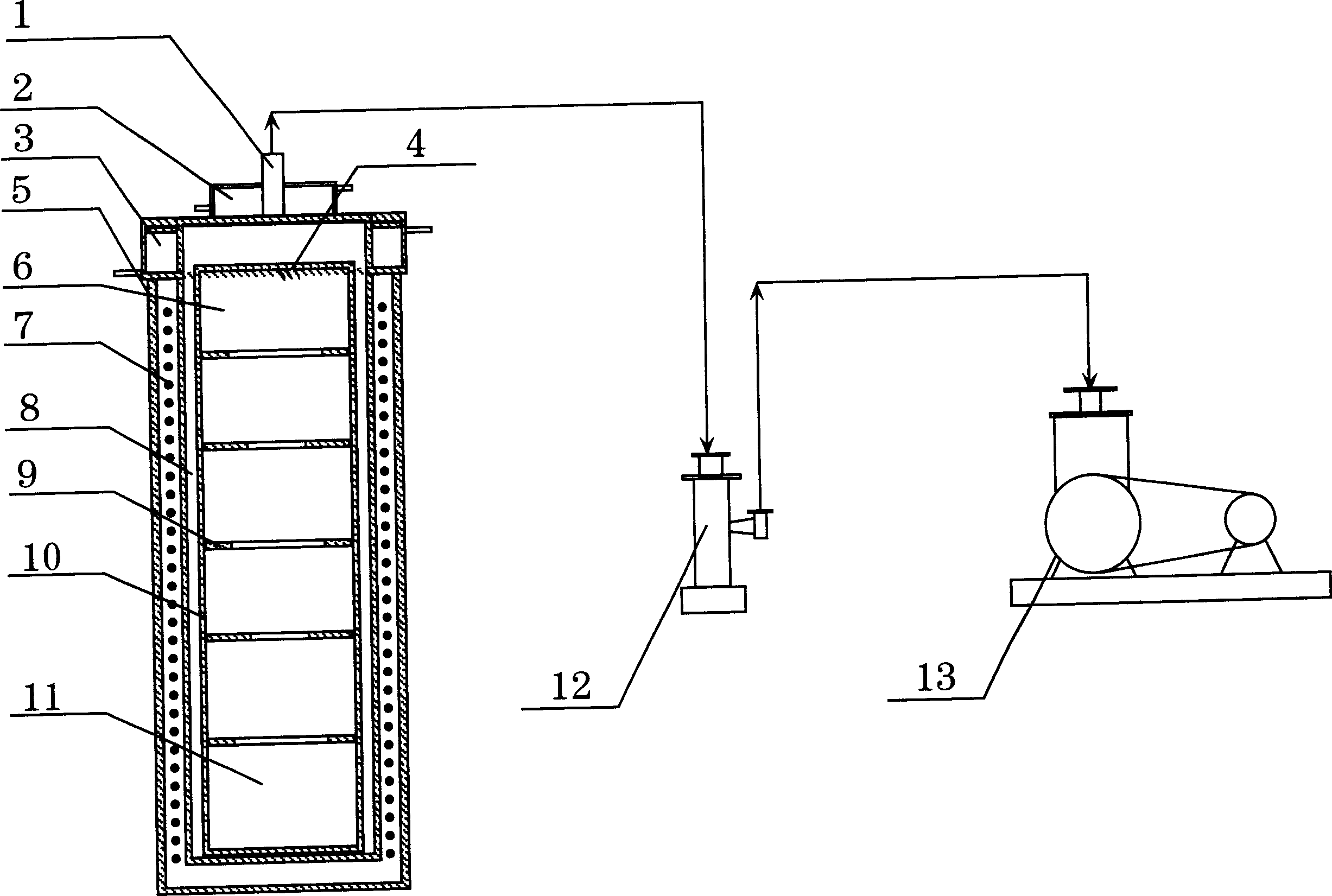

Embodiment 1

[0021] Crush 350 kg of 1# industrial antimony into irregular blocks of Φ20-Φ40, place it in the evaporator 11, place the tray 9, condenser 10, collector 6 and collector cover 4 in order, and start the heating device 7 , The temperature of the evaporator is controlled at 750°C to melt the metal antimony block and form a vapor pressure. The vacuum chamber pressure is controlled at 1Pa. The temperature of the first, second and third sections is controlled at 550°C, and the temperature of the fourth section is controlled at 350°C.

[0022] The metal antimony melts and evaporates, and under the action of the diffusion pump 12 and the vacuum mechanical pump 13, the antimony vapor evaporates upward along the tray holes. The first large-aperture tray separates the impurities with t>1 evaporated simultaneously with the antimony, and keeps them in the crucible, and the second small-aperture tray further separates the impurity elements with a t slightly greater than 1 in the vapor. Lef...

Embodiment 2

[0028] Repeat Example 1, with the following differences: the temperature of the evaporator is controlled at 800°C, the pressure of the vacuum chamber is controlled at 0.5Pa, the temperature of the first to third condensation sections is controlled at 700°C, and the temperature of the fourth condensation section is controlled at 400°C to obtain a grade of 99.999 % metal antimony.

Embodiment 3

[0030] Repeat Example 1, with the following differences: the vacuum chamber pressure is controlled at 0.5Pa, the temperature of the first to third condensation sections is controlled at 600°C, and the temperature of the fourth condensation section is controlled at 400°C; Metal antimony 120 kg. The results detected by the glow discharge mass spectrometer are shown in Table 2.

[0031] Impurity name

[0032] *Interference exists

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com