Biaxially oriented multi-layer film using propylene-ethylene random block copolymer as a surface layer

A random copolymer, biaxially oriented technology, applied in the field of biaxially oriented multilayer films

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0169] Preparation of a sample: A sample solution having a concentration of 1 mg / mL was prepared at 140° C. using o-dichlorobenzene (containing 0.5 mg / mL of BHT) as a solvent.

[0170] The amount of components with a molecular weight less than 5000 can be determined by plotting the elution amount against the molecular weight obtained by GPC testing.

[0171] (1-8) Intrinsic viscosity [η]cxs of cold xylene solubles

[0172] The cold xylene solubles (CXS) of the random block copolymer will affect the anti-blocking property when exuding. CXS is a component soluble in xylene at 23°C, so the intrinsic viscosity of CXS is tested.

[0173] Get CXS as follows. The block copolymer samples were dissolved in p-xylene at 130°C and then left at 23°C for 12 hours. The precipitated polymer was removed by filtration, and p-xylene was distilled off from the filtrate to obtain CXS. The intrinsic viscosity ([η]cxs) of the CXS thus obtained was measured at 135°C using decalin as a solvent and ...

Embodiment

[0284] The present invention is further illustrated according to the following examples and comparative examples, but the present invention should not be limited thereto.

[0285] Various physical properties of the block copolymers obtained in the following Examples and Comparative Examples were measured according to the following methods.

[0286] 1) Melt flow rate (MFR)

[0287] According to the method condition M of JIS K7210A, the melt flow rate was tested under the following conditions.

[0288] Test temperature: 230°C

[0289] Nominal load: 2.16kg

[0290] Die shape: diameter 2.095mm, length 8.00mm

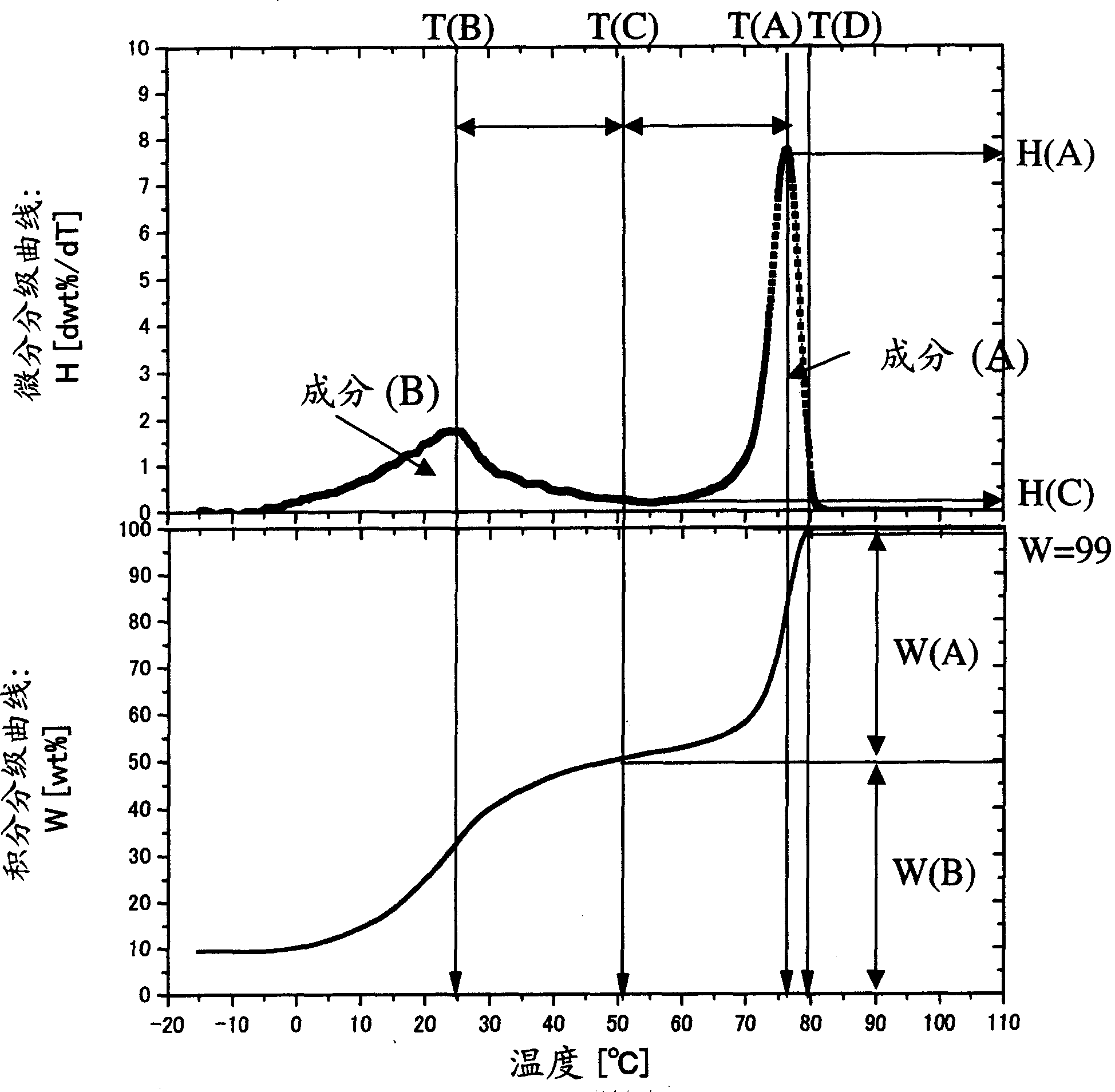

[0291] 2) TREF

[0292] The TREF test method is specifically as described above.

[0293] equipment

[0294] (TREF part)

[0295] TREF column: stainless steel column with a diameter of 4.3mm and a length of 150mm

[0296] Column packing: 100μm glass beads with surface inert treatment

[0297] Heating system: aluminum heating block

[0298] Cooling system: Peltier E...

preparation example 1

[0367] Preparation of prepolymerized catalyst

[0368] (chemical treatment of silicates)

[0369] Add 3.75 liters of distilled water to a 10 liter glass separatory flask equipped with a stirrer, and then slowly add 2.5 kg of concentrated sulfuric acid (96%). Disperse 1 kg of montmorillonite (Benclay SL manufactured by Mizusawa Chemical Co., Ltd., average particle size = 25 μm, particle size distribution = 10-60 μm) therein at 50° C., heat the resulting suspension to 90° C., and maintain 6.5 μm at this temperature. Hour. After cooling to 50°C, the suspension was filtered under reduced pressure to recover the filter residue. The filter residue was dispersed with 7 liters of distilled water, followed by filtration. This elution procedure was repeated until the pH of the wash (filtrate) exceeded 3.5. The filter residue thus recovered was dried at 110° C. overnight in a nitrogen atmosphere. After drying, 707 g of silicate were obtained.

[0370] (drying of silicates)

[0371...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com