Method for regenerating sodium cyanide from solutions containing cyanogen and thiocyanate

A technology containing thiocyanate and thiocyanate, applied in cyanic acid/isocyanic acid, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of regenerated cyanide, high power consumption, unsuitability and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

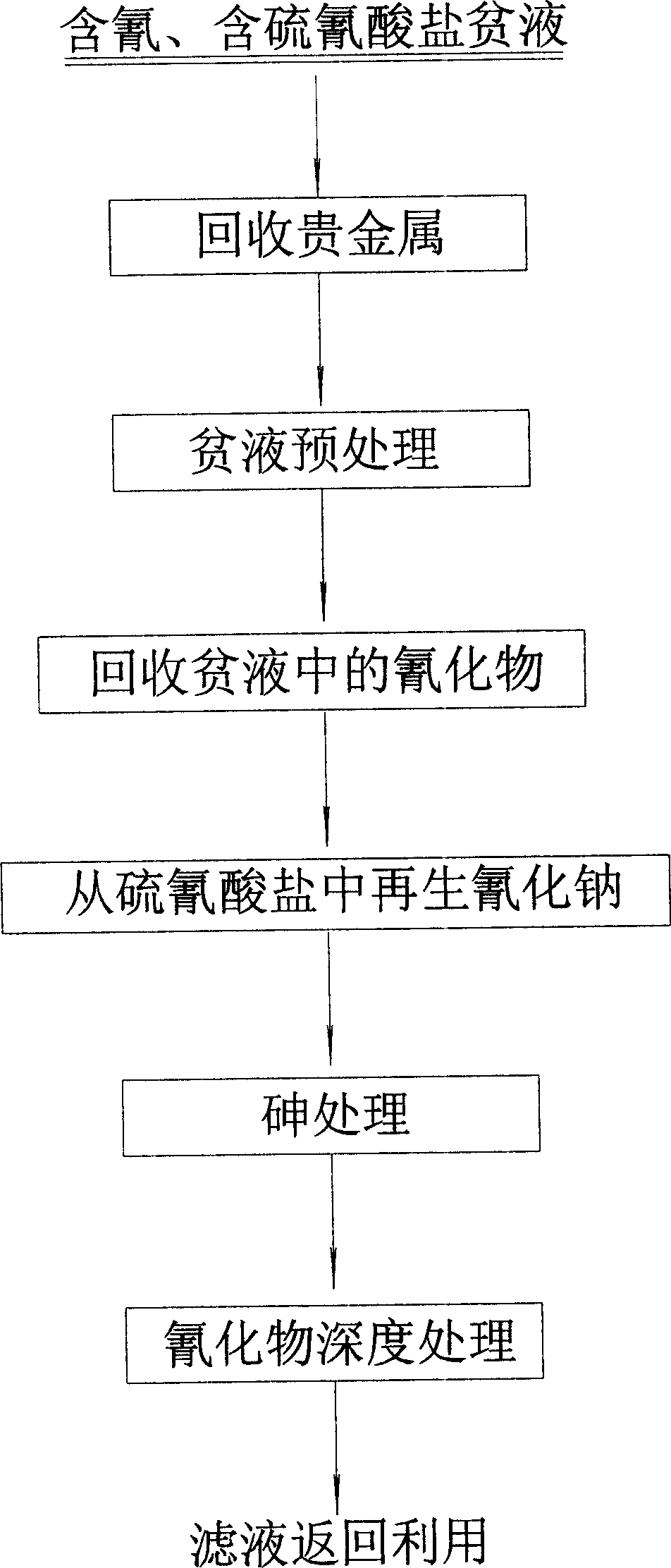

[0042] as attached figure 1As shown, the present embodiment is carried out according to several steps in the following order: wherein the barren solution to be treated is biological oxidation——a cyanidation plant in which the refractory concentrate is used as the cyanide nuclear material in the cyanidation process, because the gold in the concentrate , high silver grade, and relatively high content of associated minerals, so the consumption of sodium cyanide is also high in the cyanidation process. The composition of the barren solution is shown in Table 1:

[0043] composition

CNT

CN -

Cu

Pb

Zn

Concentration mg / l

5360.12

4423.4

31.67

0.23

630

composition

Fe

SCN -

As

Au

Concentration mg / l

11.10

6366.08

6.00

0.10

6288

[0044] When pH = 2, the acidification of cyanide-occurrence and the oxidation of thiocyanate-occurrence a...

Embodiment 2

[0075]Carry out embodiment 1 repeatedly by the above-mentioned identical steps, but difference is, step 3 and step 4 carry out simultaneously, and each technical parameter is identical with step 3 and step 4 of embodiment 1; Its operating procedure is to add concentrated sulfuric acid to adjust pH earlier After the value is 2, add hydrogen peroxide in time to a concentration of 28kg / m 3 , then acidification, oxidation—aeration occurs—absorption takes place for 6 hours.

[0076] After embodiment 2 is processed by the above-mentioned method, the recovery rate of precious metals such as gold and silver reaches 95.02% in step 1, and in step 3 and step 4, the cyanide in the barren solution and regenerated sodium cyanide from thiocyanate The total recovery rate of cyanide is 81.51%. In step 5, the arsenic concentration after neutralization treatment is 0.16mg / l, which is lower than the industrial secondary discharge standard of 0.5mg / l. After the cyanide is advanced in step 6, The ...

Embodiment 3

[0078] Carry out embodiment 1 repeatedly by the same steps as described, but the difference is that the gas-liquid ratio in step 3 and step 4 is adjusted to 300, and other various technical parameters and steps are the same as embodiment 1, and the difference is that step 3 is carried out 2 hours, step 4 is also carried out for 2 hours.

[0079] After embodiment 3 is processed by the above method, in step 1, the recovery rate of precious metals such as gold and silver reaches 95.08%, and in step 3, the recovery rate of cyanide in the barren solution is 99.68%, and in step 4, from thiocyanic acid The regeneration rate of regenerated sodium cyanide in the salt is 86.76%, and the total recovery rate of cyanide is 94.81%. In step 5, the arsenic concentration after the neutralization treatment is 0.08mg / l, which is lower than the industrial secondary discharge standard of 0.5mg / l, in step 6, the total cyanide after advanced treatment of cyanide is 0.12, lower than the industrial s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com