Macroporous brushite bone cement with latent hole forming agent and preparation process thereof

A porosity calcium phosphate rock and bone cement technology, applied in latent macroporous calcium phosphate rock bone cement and its preparation, in the field of biomedical bone materials, can solve the problems of poor plasticity, poor binding stability, slow HA degradation rate, etc. , to achieve good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Mix the powders of β-tricalcium phosphate and monocalcium phosphate monohydrate salt in a molar ratio of 1.22:1 to form a composite calcium phosphate salt powder, and then add 1% by weight of dry powder to the composite powder. The rubber powder is mixed evenly to be used as brushite bone cement powder. Then mix the above-mentioned bone cement powder with 0.2mol / L sodium pyrophosphate aqueous solution at a weight ratio (P / L) of 2.7:1, adjust it into a paste, and make a Φ9mm×12mm sample, put Put into 37 ℃ and 100% humidity environment to cure, the measured average curing time is 7min, and the average compressive strength reaches 13.8MPa.

Embodiment 2

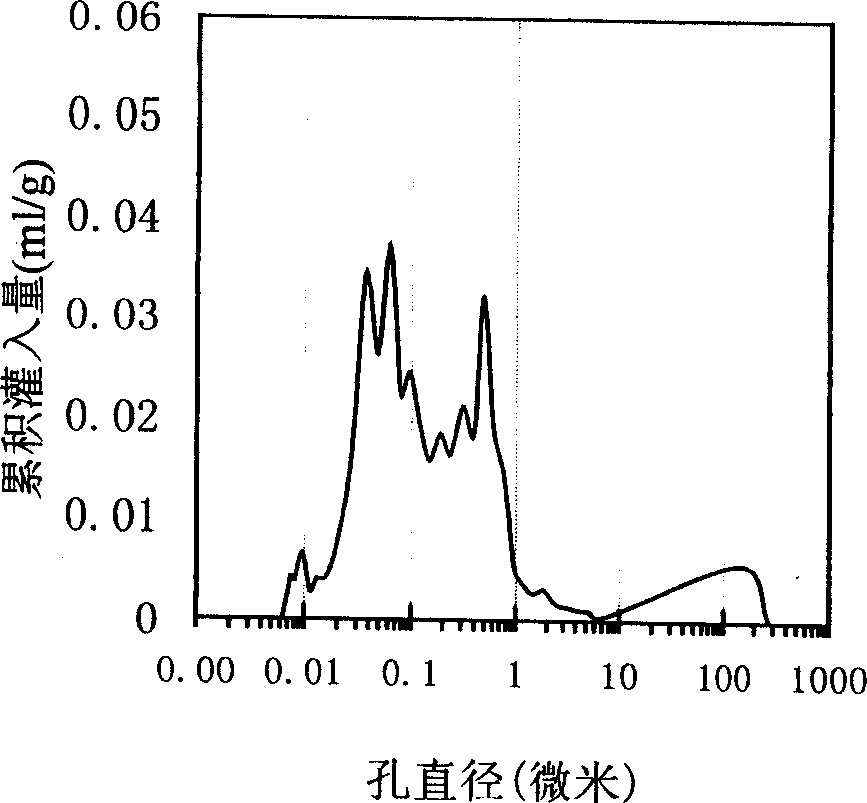

[0024] Except that 8% by weight dry gelatin powder was added to the composite calcium phosphate salt powder when preparing the brushite bone cement powder, the rest of the preparation methods and processes refer to Example 1. The latent macroporous brushite bone cement obtained in this example has an average curing time of 16 minutes and an average compressive strength of 5.6 MPa, reaching the level of cancellous bone.

Embodiment 3

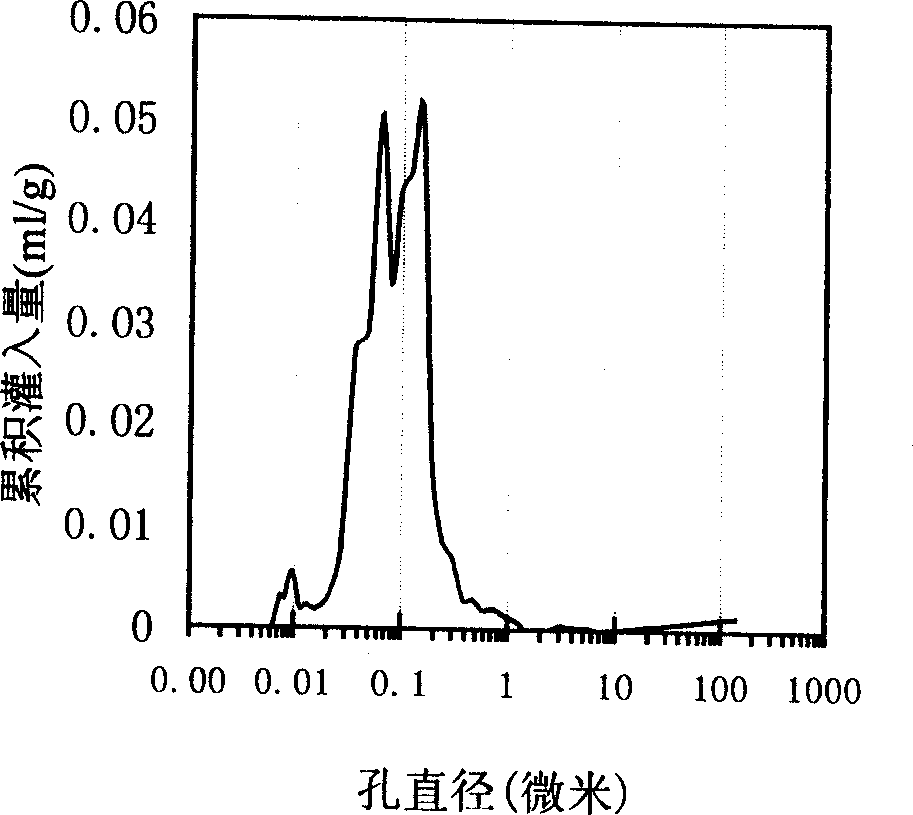

[0026] The composite calcium phosphate salt powder in Example 1 was directly mixed and solidified with sodium pyrophosphate solidification solution, without adding latent pore-forming agent gelatin. In addition, the preparation method and process of calcium phosphate bone cement refer to Example 1. The bone cement sample obtained in this example had an average curing time of 7 minutes and an average compressive strength of 15.1 MPa.

[0027] The latent macroporous calcium phosphate bone cement prepared by the above-mentioned embodiment has been carried out in vivo simulation test as follows:

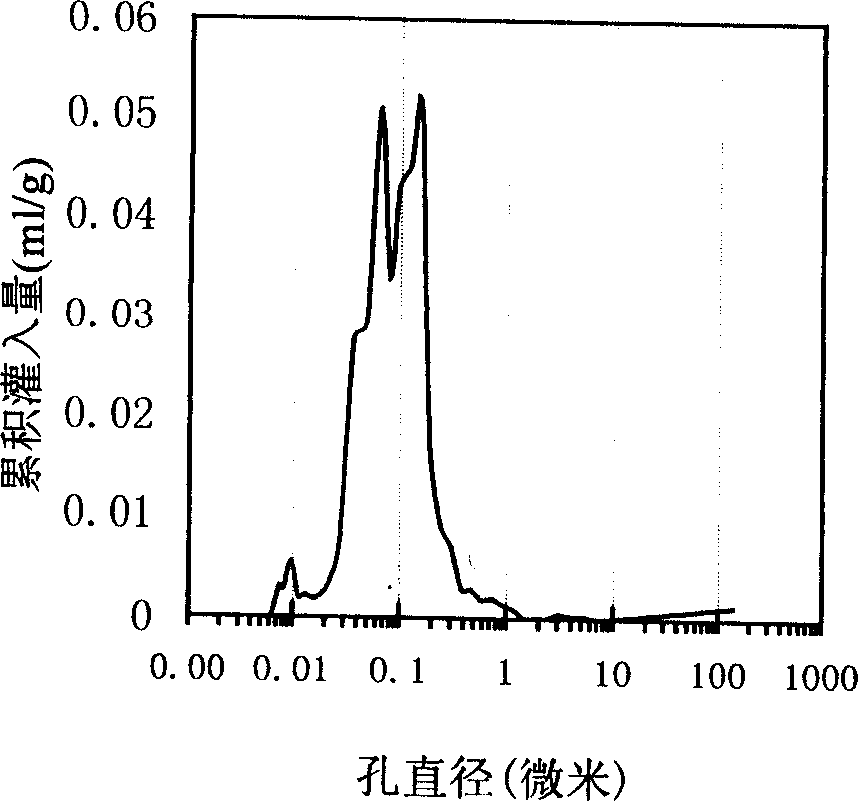

[0028] The above-mentioned uniformly prepared brushite bone cement paste was injected into a 2ml plastic mold to make a sample of Φ9mm×12mm. Then place the sample in an environment of 37°C and 100% humidity, measure the curing time after curing, and then soak the cured body in phosphate buffer solution (PBS, pH=7.4) at 37°C for 1 week, at this time The gelatin dissolves to form a large ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com