Beta-mannase gene and preparation thereof

A technology of mannanase and gene, applied in genetic engineering, DNA preparation, plant gene improvement, etc., can solve the problem that the fermentation level cannot meet the needs of industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0085] Example 1 Conditions and purification of Bacillus licheniformis ATCC14580 producing β-mannanase

[0086]On the basis of inorganic salt solution, add 15-25g / L locust bean gum as a carbon source, 5-20g / L peptone as a nitrogen source, the fermentation temperature is 37-40°C, and the inoculum size can be selected as 1%. , the filling volume is 70mL (250mL Erlenmeyer flask), and the pH can be selected as 7.0 under optional conditions. Under this process condition, the average enzyme activity of shake flask fermentation for 12h is 41.92u / mL, and the supernatant culture fluid is collected as crude enzyme solution, after purification, the specific enzyme activity reached 2862.4u / mg.

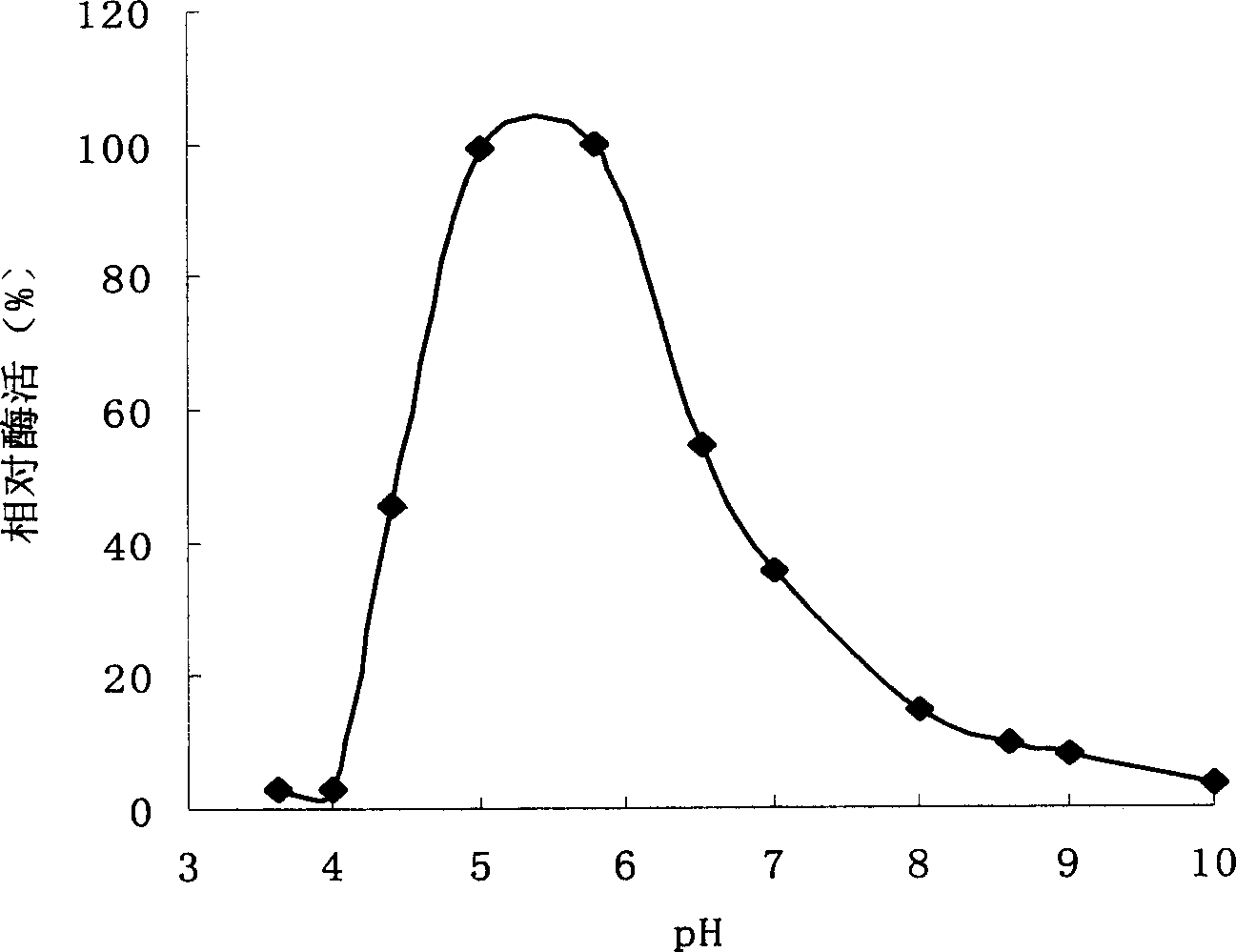

[0087] β-Mannanase activity assay used locust bean gum as substrate. The reaction mixed liquid contained 1.5 ml locust bean gum solution (5 g / L) prepared with 0.1 mol / L sodium acetate buffer (pH 5.8) and 0.02 ml appropriately diluted (about 20 U / ml) enzyme solution. The mixture was incubated at ...

Embodiment 2

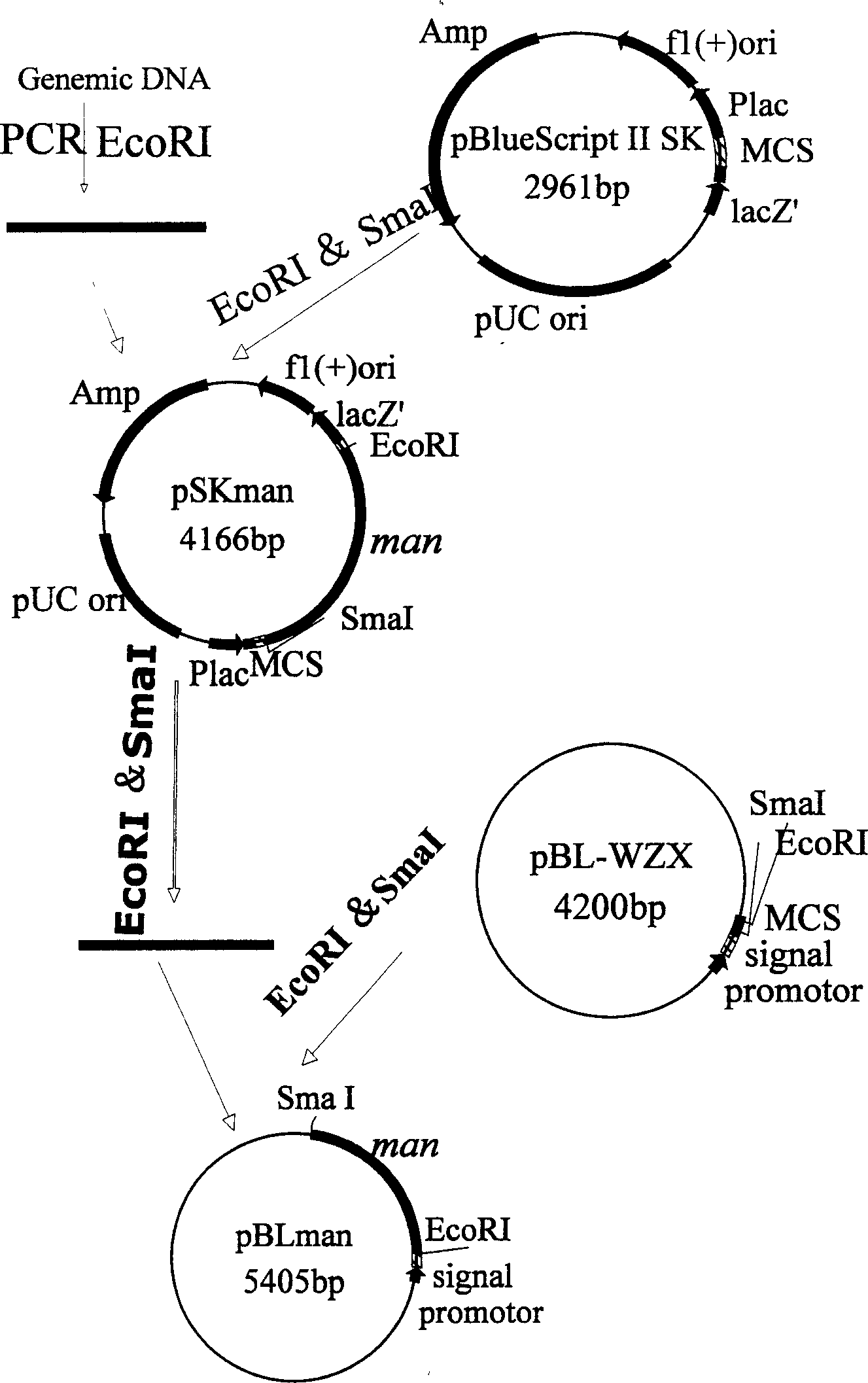

[0088] Embodiment 2: Cloning of β-mannanase gene and construction of recombinant plasmid

[0089] Primers BL0-manS1ggcttgaggcgatgctgagcaaaat and BL0-manS2aaaggagagatatgggacggcgattc were designed according to the reported conserved sequence of the Bacillus β-mannanase gene, and a 550bp fragment was amplified by PCR using the chromosomal DNA of Bacillus licheniformis ATCC14580 as a template. The amplified fragment was analyzed as the gene encoding β-mannanase. Based on this, primers B0-manS3taagggagcggacaccctctatctt and B0-manS4aacgggcacgccttcattttcaa were designed. The chromosomal DNA of Bacillus licheniformis ATCC14580 was partially digested with Sau3AI, and the 3-4kb DNA fragment was recovered, which was used as a PCR template after self-circularization, and a 3.2kb band was amplified with primers BL0-manS3 and BL0-manS4, sequenced and analyzed. The nucleotide sequence of the full-length man gene was obtained by splicing with the 550bp DNA sequence.

[0090] The chromosomal...

Embodiment 3

[0091] Example 3: Expression of β-mannanase gene in Escherichia coli

[0092] The recombinant plasmid pBL-man was transformed into Escherichia coli JM109, and the recombinant Escherichia coli EC-man was obtained through double resistance selection of ampicillin and kanamycin.

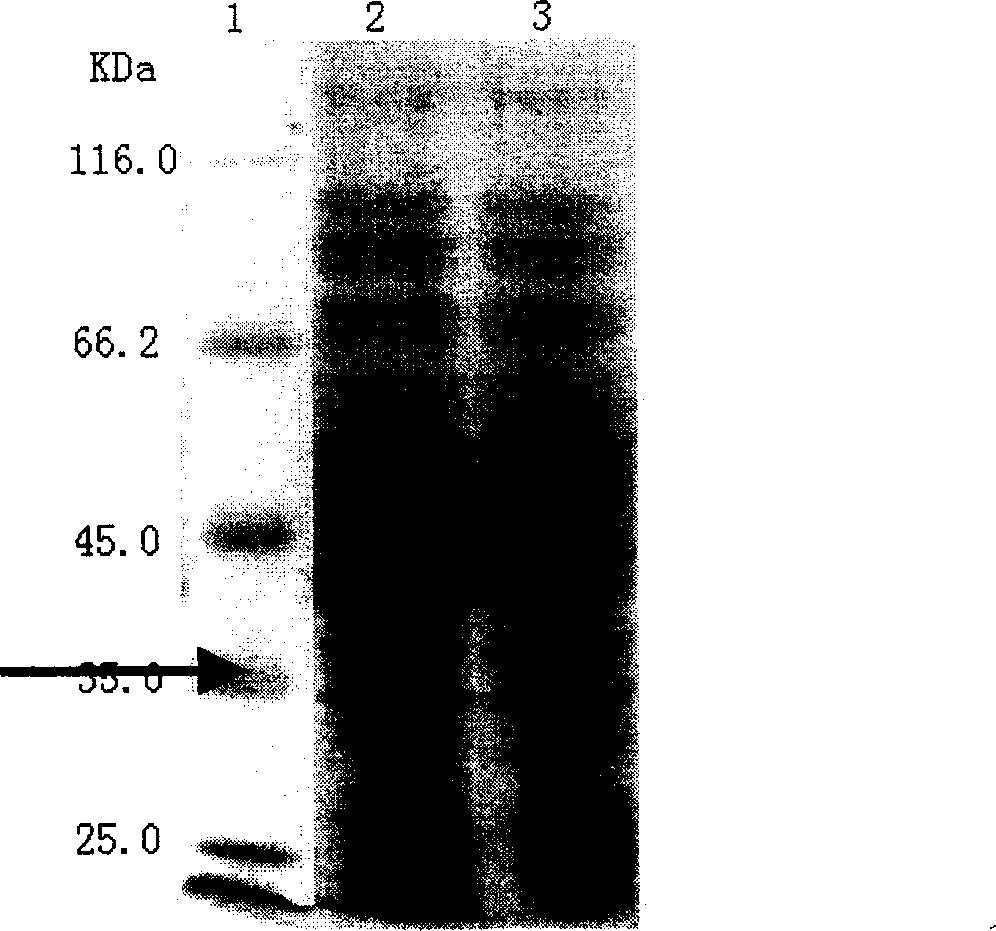

[0093] Recombinant Escherichia coli EC-man was cultured in liquid LB (Amp+Kan) medium with a liquid volume of 35ml (250ml Erlenmeyer flask), 37°C, 200r / min. After culturing for 48 hours, the supernatant was centrifuged and analyzed for enzyme activity. The highest level of β-mannanase produced by recombinant Escherichia coli EC-man reached 0.9 mg / ml, which was about the enzyme activity of Bacillus licheniformis ATCC14580 under the optimal culture conditions. 59 times. Taking Escherichia coli JM109 (pBL-WZX) as a control, the 12h culture of the recombinant strain EC-man was analyzed by whole-cell SDS-PAGE, and the results were as follows: figure 2 As shown, the sample has an obvious expression band at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com