Anodic oxidation method and production method for titanium oxide coating and method of supporting catalyst

An anodizing method, titanium oxide film technology, applied in anodizing, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of unusability, low solubility, and high price of catalyst-carrying solution, and achieve the improvement of operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

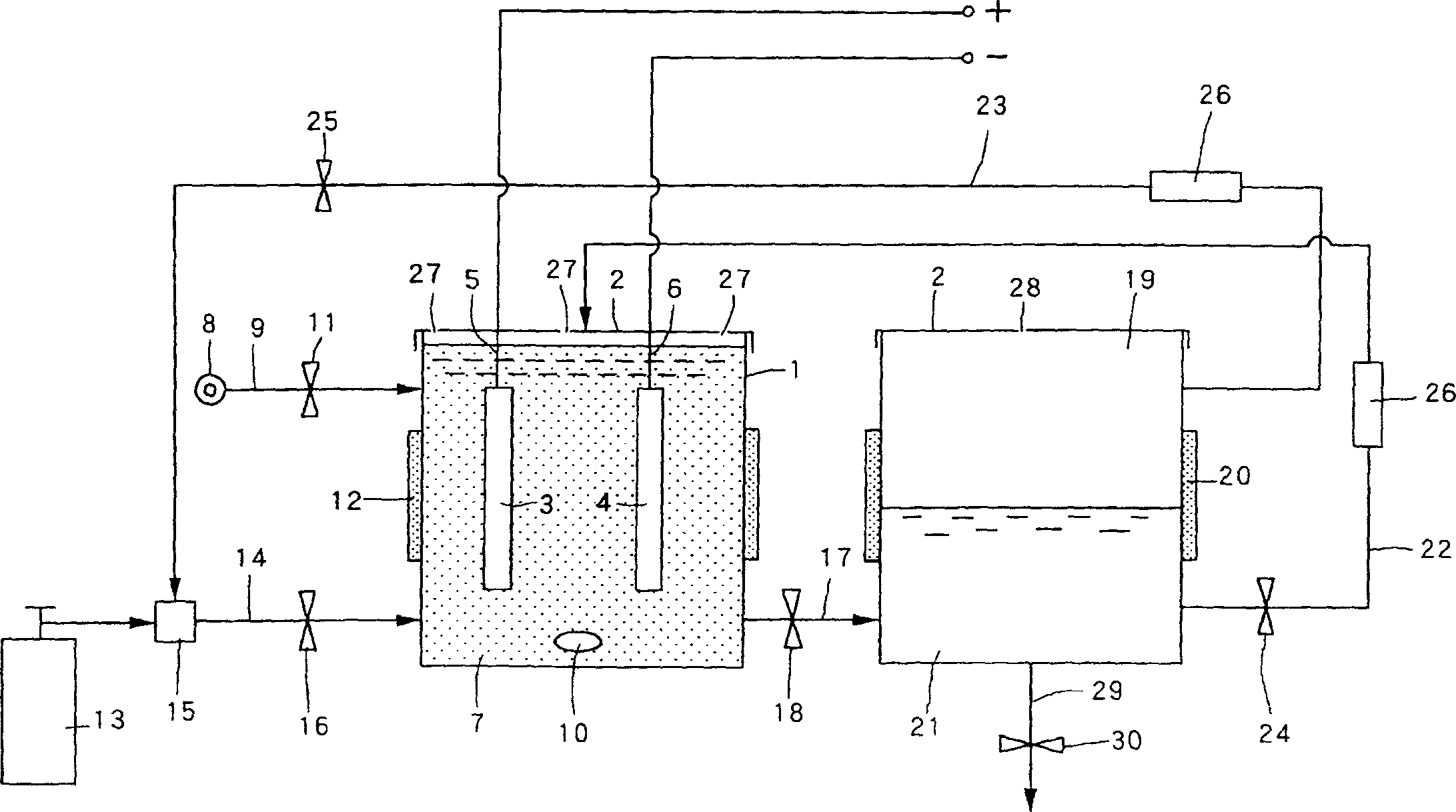

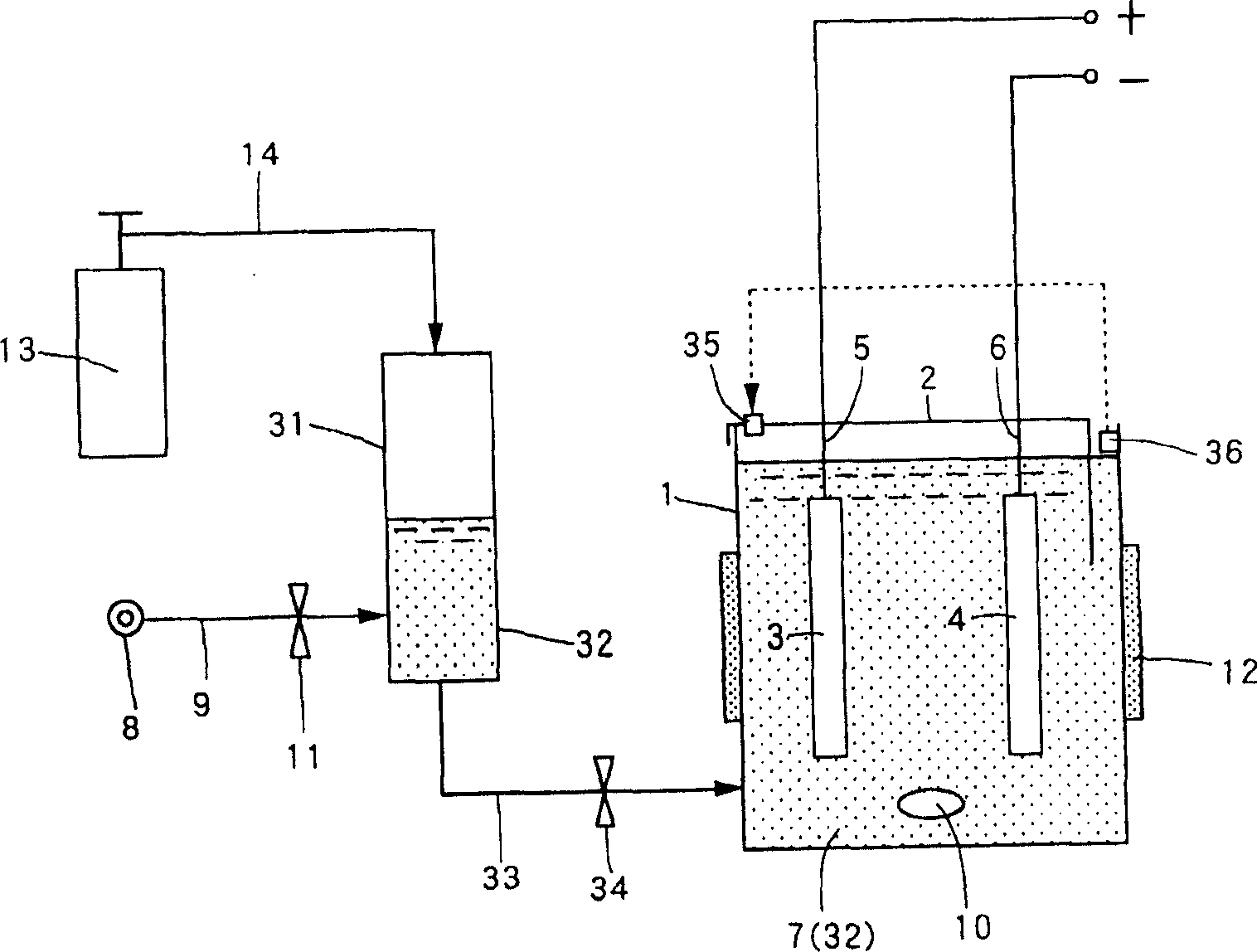

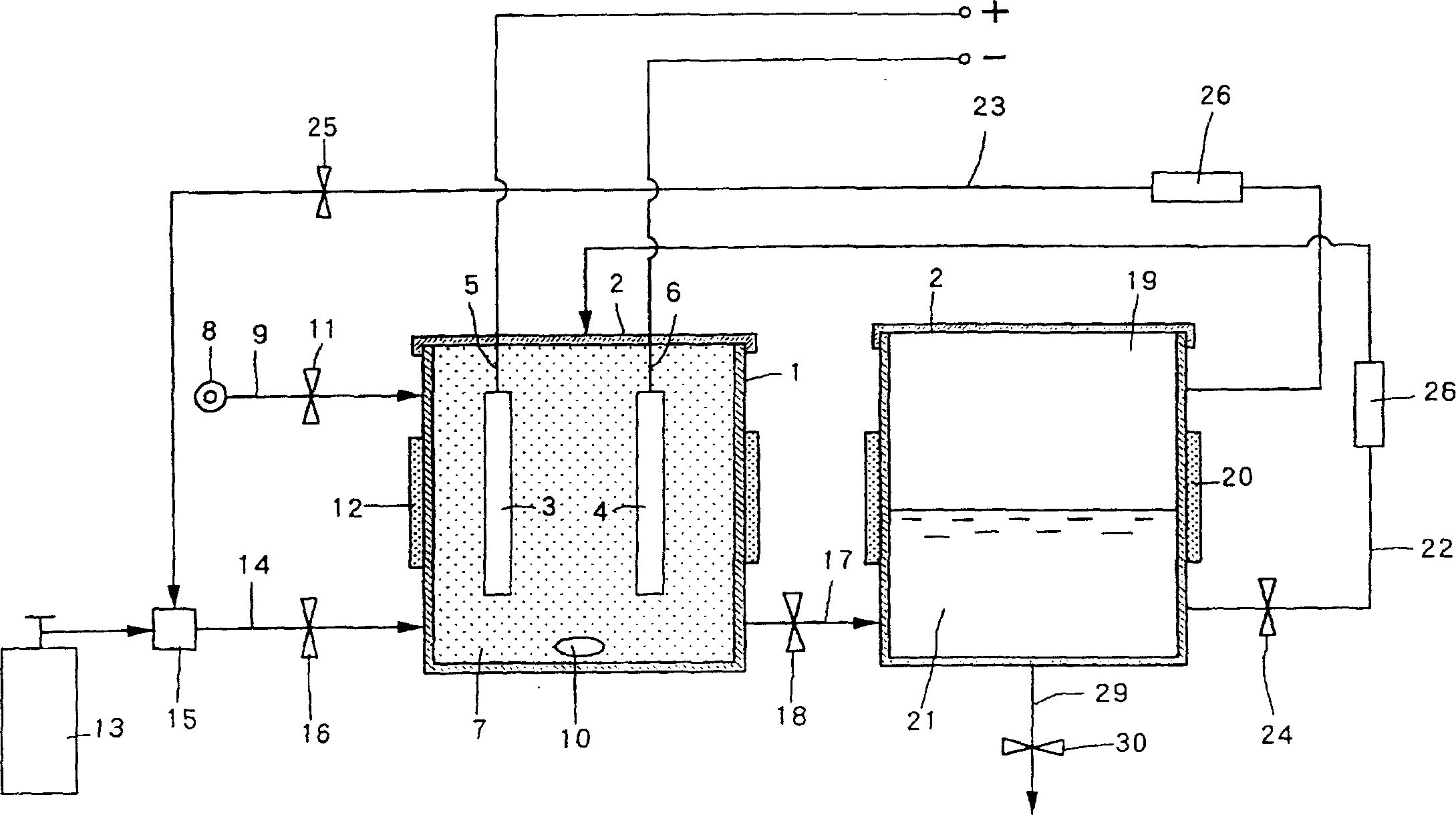

[0084] Hereinafter, an exemplary embodiment in which the present invention is applied to an anodic oxidation method in which the processed member is aluminum or its alloy will be described. figure 1 Among them, 1 is a bottomed treatment tank made of stainless steel, the inner surface is lined with vinyl chloride, etc., and a detachable cover body 2 is installed on the upper opening.

[0085] The aluminum processed member 3 and the lead plate and other cathode materials 4 that are the object of anodic oxide film formation are suspended in the above-mentioned processing tank 1 through the hooks 5 and 6 in a manner that can enter and exit. These are coupled to the power supply device positive and negative poles.

[0086] Water 7 , such as tap water and distilled water, which is an electrolytic solution generation material is contained in the treatment tank 1 , and a water supply pipe 9 connected to a water supply source 8 is connected to the peripheral surface of the upper end. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com