Hydrothermal method for preparing nano crystal Bi2WO6 powder photocatalytic material with visible light activity

A photocatalytic material and visible light technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve problems such as lack of homogeneity and decrease in specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

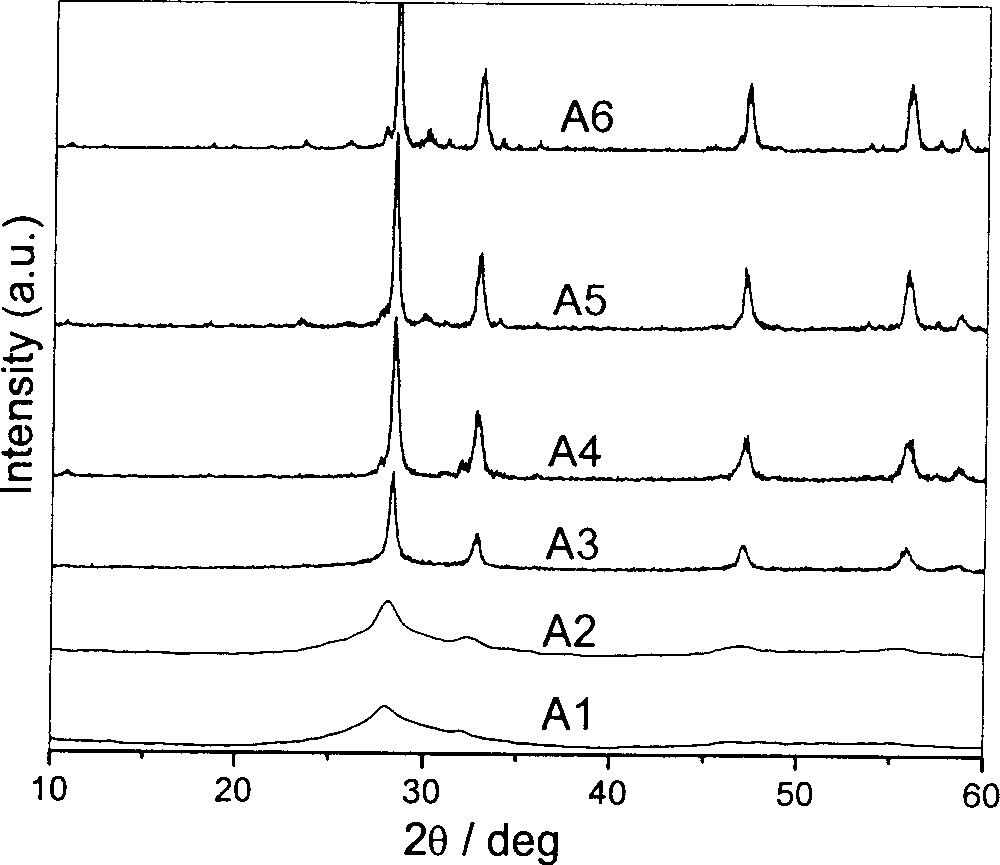

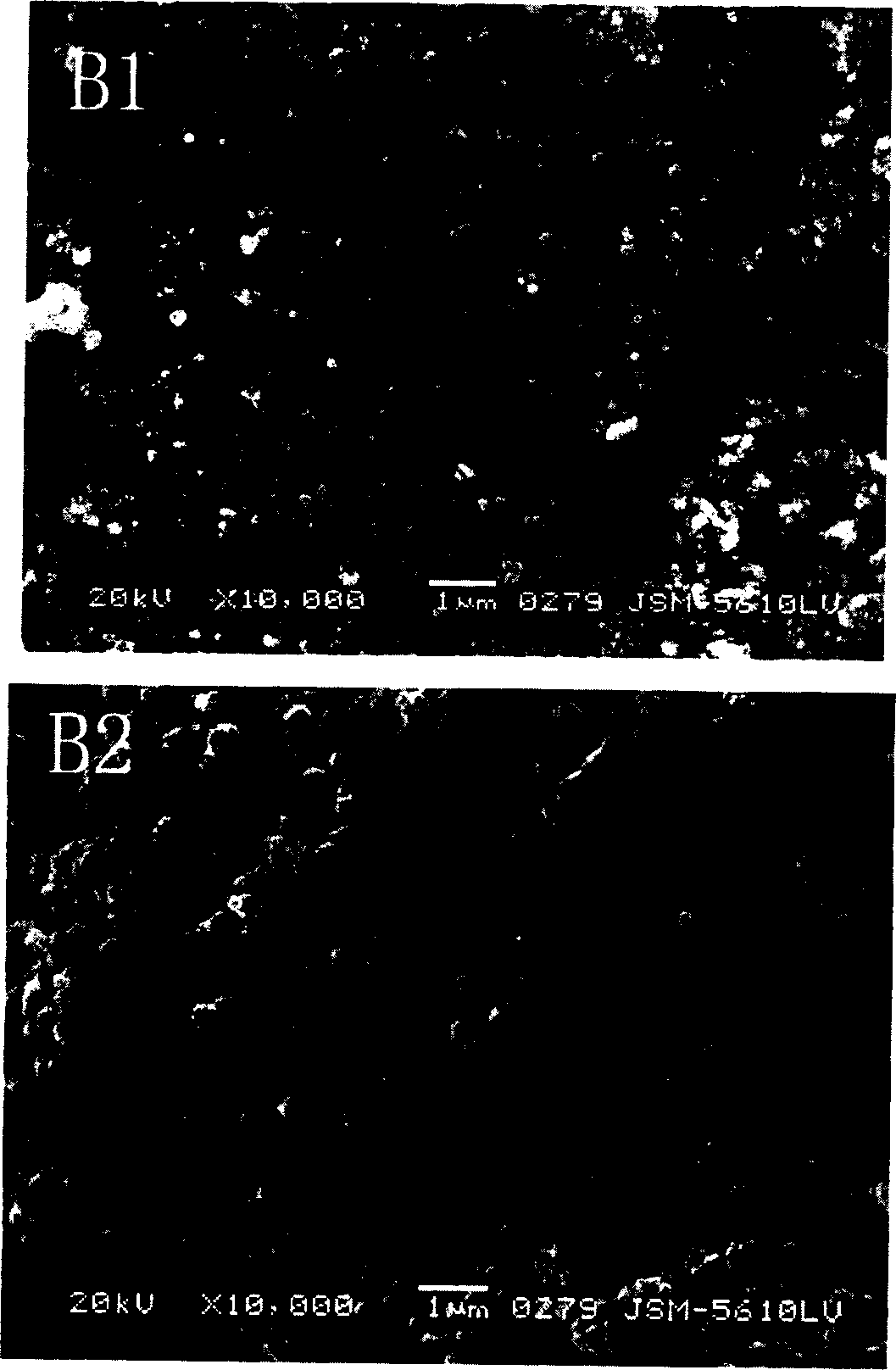

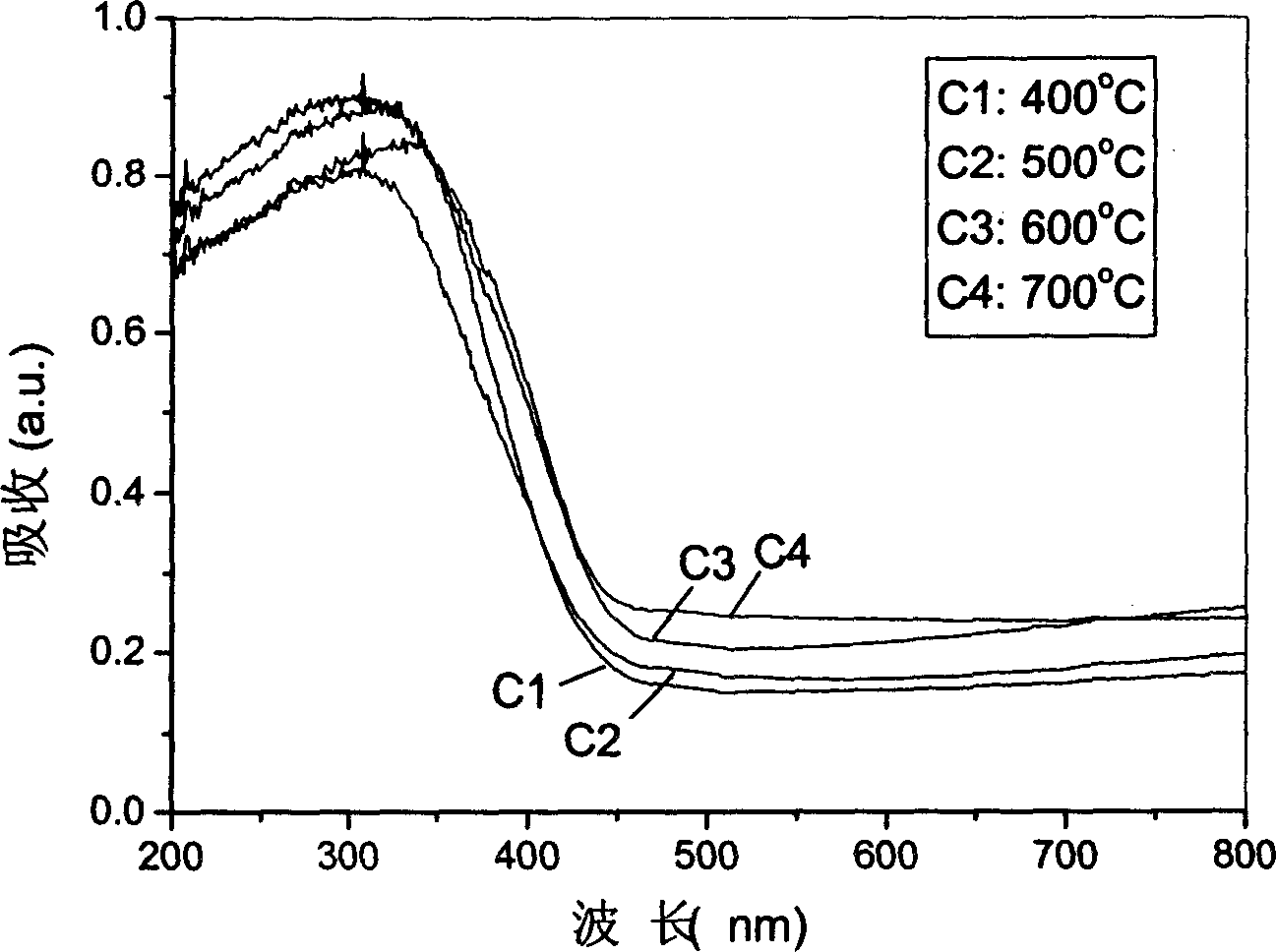

[0026] Preparation of Nanocrystalline Bi by Hydrothermal Method 2 WO 6 The method of powder photocatalyst is as follows: first weigh 9.8g Na 2 WO 4 ·2H 2Dissolve O in 150ml distilled water and stir constantly; then weigh 7.2g Bi(NO 3 ) 3 ·5H 2 O was added to the above solution, stirring constantly. After stirring for about 15 minutes, the above reaction solution was put into a 200 ml reactor, and hydrothermally treated at 150° C. for 24 hours. Take out the reaction kettle, after the reaction kettle is cooled to room temperature, separate the precipitate, wash the obtained precipitate repeatedly with distilled water until it is neutral, and finally vacuum dry at 80°C to obtain Bi 2 WO 6 powder. Bi to be obtained 2 WO 6 The powder was heat treated at 500°C for 2h. So you get nano crystal Bi 2 WO 6 catalyst of light. This sample showed the best photocatalytic activity, and its visible light photocatalytic degradation rate reached 68.7%.

Embodiment 2

[0028] In order to examine the effect of hydrothermal treatment temperature on nanocrystalline Bi 2 WO 6 The effect of the photocatalyst's catalytic activity, except for the difference in hydrothermal temperature, other reaction conditions such as the concentration of reactants, the amount of solvent water, the hydrothermal time, and the heat treatment temperature are exactly the same as in Example 1. It was found that when the hydrothermal treatment temperature was 100, 150, and 180°C, the visible light photocatalytic degradation rates were 13.7%, 68.7%, and 69.7%, respectively. The reason may be that when the hydrothermal temperature is too low, the reaction is incomplete, the yield is low, there are many impurities, and the photocatalytic activity is weak; when the hydrothermal temperature rises to 150°C, the nanocrystalline Bi 2 WO 6 The photocatalyst exhibits good photocatalytic activity; when the temperature is further increased, the photocatalytic activity of the sample doe...

Embodiment 3

[0030] In order to test the hydrothermal time for nanocrystal Bi 2 WO 6 The effect of the photocatalyst's catalytic activity, except for the difference in hydrothermal time, other reaction conditions such as the concentration of reactants, the amount of solvent water, the hydrothermal temperature, and the heat treatment temperature are all the same as in Example 1. It was found that when the hydrothermal treatment time was 10, 20, 24, and 40, the visible light photocatalytic degradation rates were 23.5%, 56.9%, 68.7%, and 70.2%, respectively. The reason may be that when the hydrothermal time is too short, the reaction is incomplete, the yield is low, there are many impurities, and the photocatalytic activity is weak; when the hydrothermal time is 24 hours, the nanocrystalline Bi 2 WO 6 The photocatalyst showed good photocatalytic activity; however, when the hydrothermal time was further extended, the photocatalytic activity of the sample did not increase significantly. Therefore, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com