Preform for producing plastic optical components, method of fabricating the preform, and plastic optical fiber

A technology for optical components and preforms, which is applied in the fields of preforms for producing plastic optical components, manufacturing preforms and plastic optical fibers, and can solve problems such as the influence of average roughness on transmission characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0103] (Preparation of source material for hollow tubes)

[0104] Monomer solution containing two monomers (isobornyl methacrylate (IBXMA) and methyl methacrylate (polymerization inhibitor and both of which are completely removed from water, IBXMA / MMA=2 / 8 mass ratio)) , as a polymerization initiator, the amount is 0.02% of the monomer solution mass of di-tert-butyl peroxide, and as a chain transfer agent, the amount is 0.05% of the monomer solution mass of n-dodecanethiol After being mixed, the mixed solution was filtered through a polyester fiber (tetrafluoroethylene) membrane filter with a pore size of 0.2 μm, and was sent to a reactor at a temperature of 100° C. under nitrogen flow, and was initially polymerized for 24 hours. The mixture was then conveyed to a screw conveyor maintained at 130°C to complete polymerization within 48 hours. A polymer having an average molecular weight of 100,000 was then obtained.

[0105] (manufacturing hollow tubes)

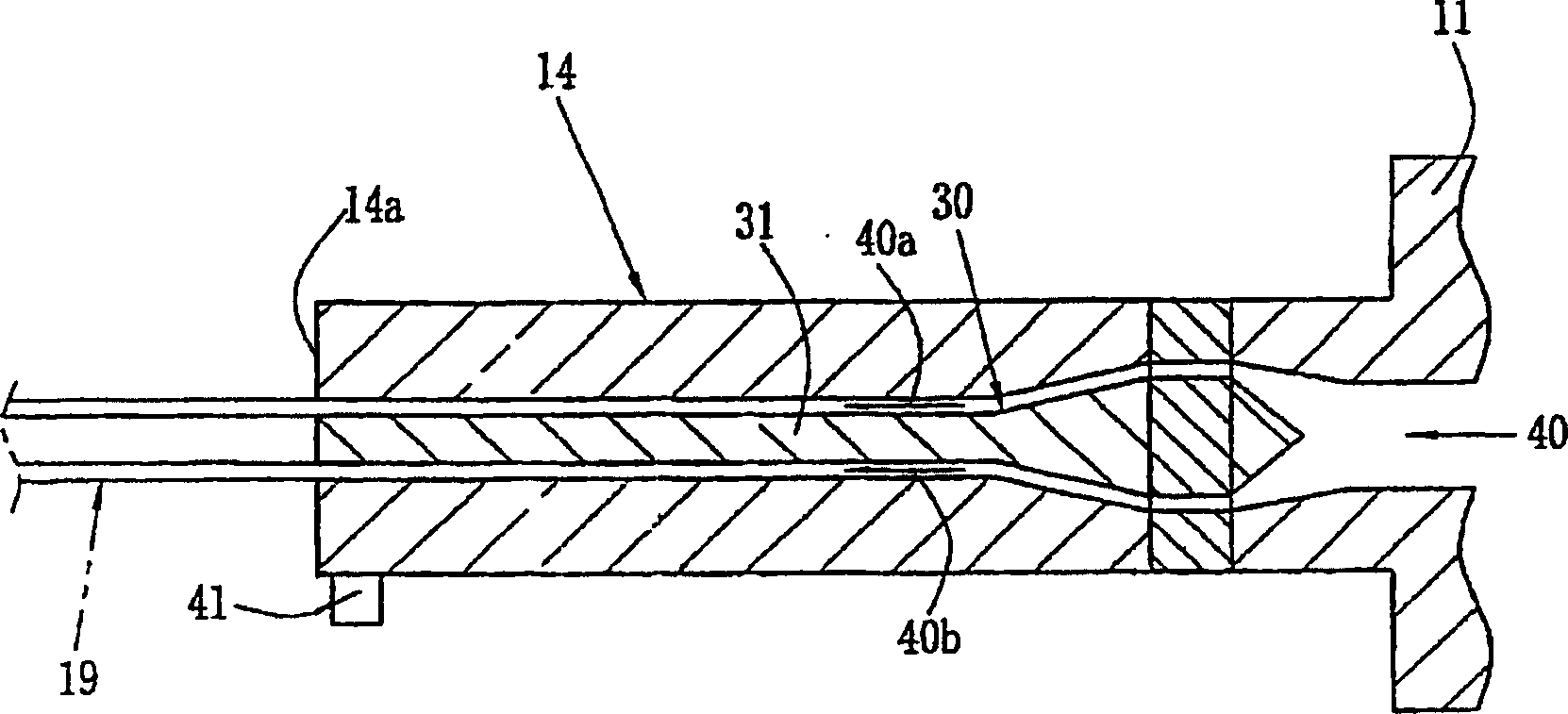

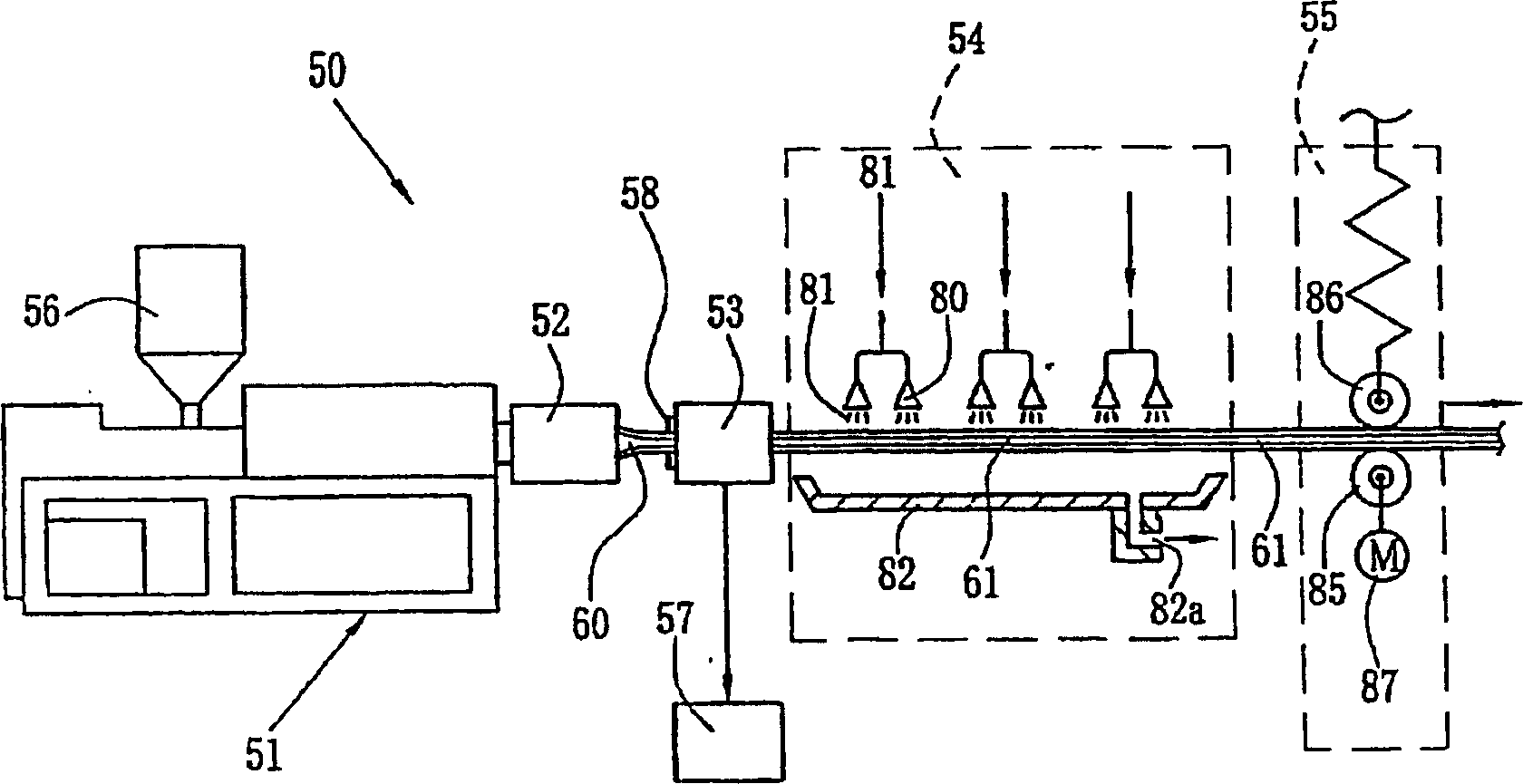

[0106] Clad pipe 61 ...

example 2

[0111] (manufacturing of double hollow tubes)

[0112] Following the conditions described in Example 1, the resin to be used was replaced by polyester fiber (vinylidene fluoride) (PVDF) (KF-#850, product of Kureha Chemical Industry Co., Ltd., m.p. = 178°C). The resin temperature was changed and adjusted to 185°C to 187°C during extrusion, and the apparent viscosity of the polymer at the exit of the pusher die was controlled within the range of 30000Pa·s to 40000Pa·s. A PVDF hollow tube with an outer diameter of 20 mm and a thickness of 0.5 mm (clad) was fabricated when other conditions were unchanged from those described in the examples.

[0113] The PVDF hollow tube thus manufactured is inserted into a hollow tube having an inner diameter size just enough to accommodate the PVDF hollow tube, and enters the hollow portion of the PVDF hollow tube. The MMA / IBXMA mixed solution is purified by the same method as described in Example 1, adding 0.05% dimethyl-2,2′-azobisbutyrate wi...

example 3

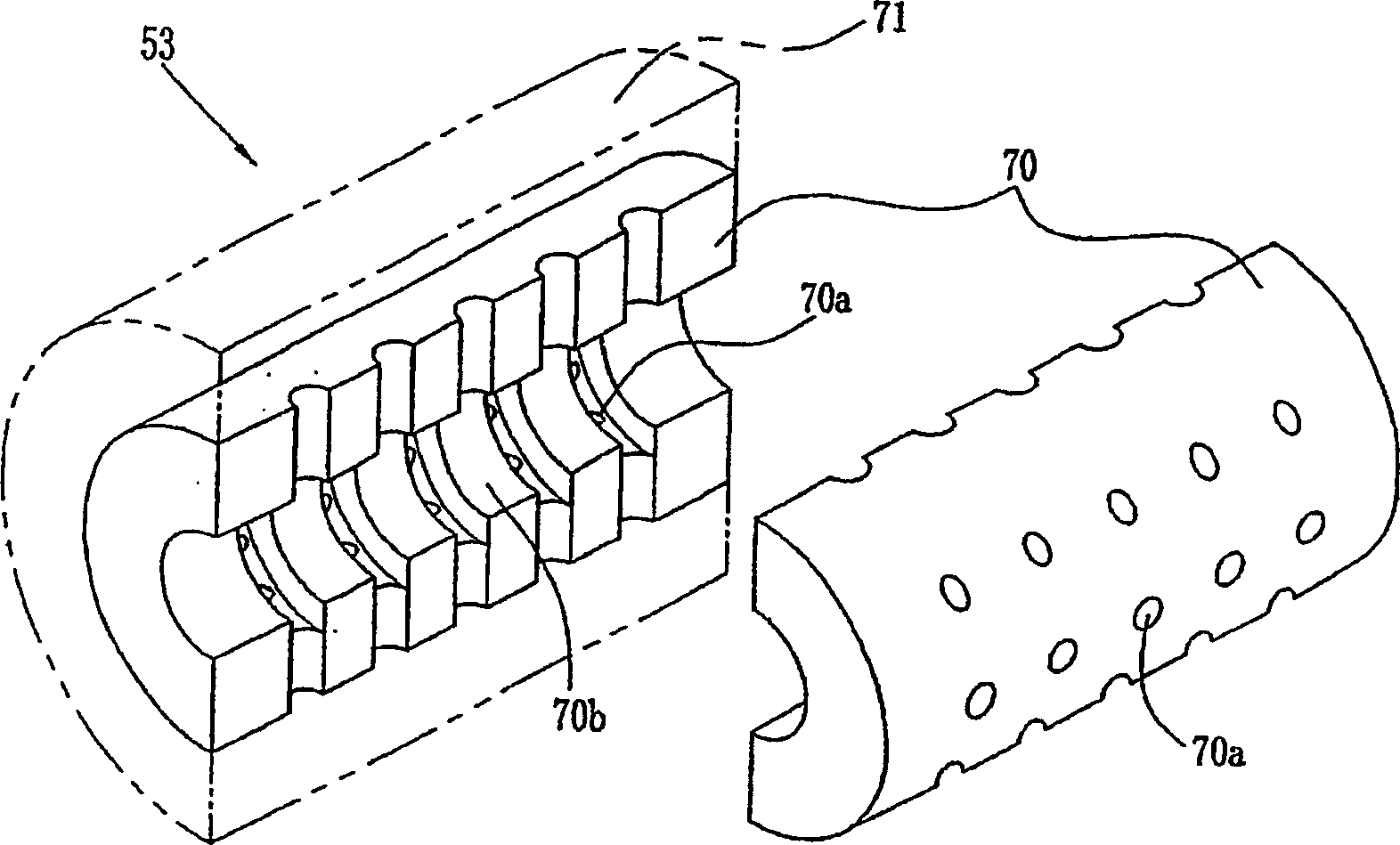

[0116] (manufacturing of double-layer hollow tubes)

[0117] The melt extruder (melt extrusion molding machine) applied to the second example was modified so that the extruder could produce double hollow tubes. This procedure employs the same PVDF resin used in Example 2 for the outer tube of the double hollow tube and the MMA / IBXMA copolymer prepared as source material for the composition of the hollow tube in Example 1 for the inner tube. Tube. After a heating process similar to Example 1, the cylindrical hollow double-clad tube has a 0.7 mm thick PVDF outer tube, and a 2.2 mm thick inner tube composed of MMA / IBXMA copolymer formed on the inner surface of the outer tube .

[0118] Thereafter, a preform was manufactured in a similar manner to that described in Example 1, and then stretched under heating to obtain an optical fiber. The fiber was found to have a measured transmission loss of 188 dB / km at 650 nm, and a maximum frequency band characteristic of 1.3 GHz / 100 m. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com