Hollow microbead reinforced epoxy resin composite material and its preparation method

A technology of hollow microbeads and epoxy resin, which is applied in the field of materials, can solve the problems of uneven texture and high density of composite materials, and achieve the effects of low water absorption, high strength and low density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

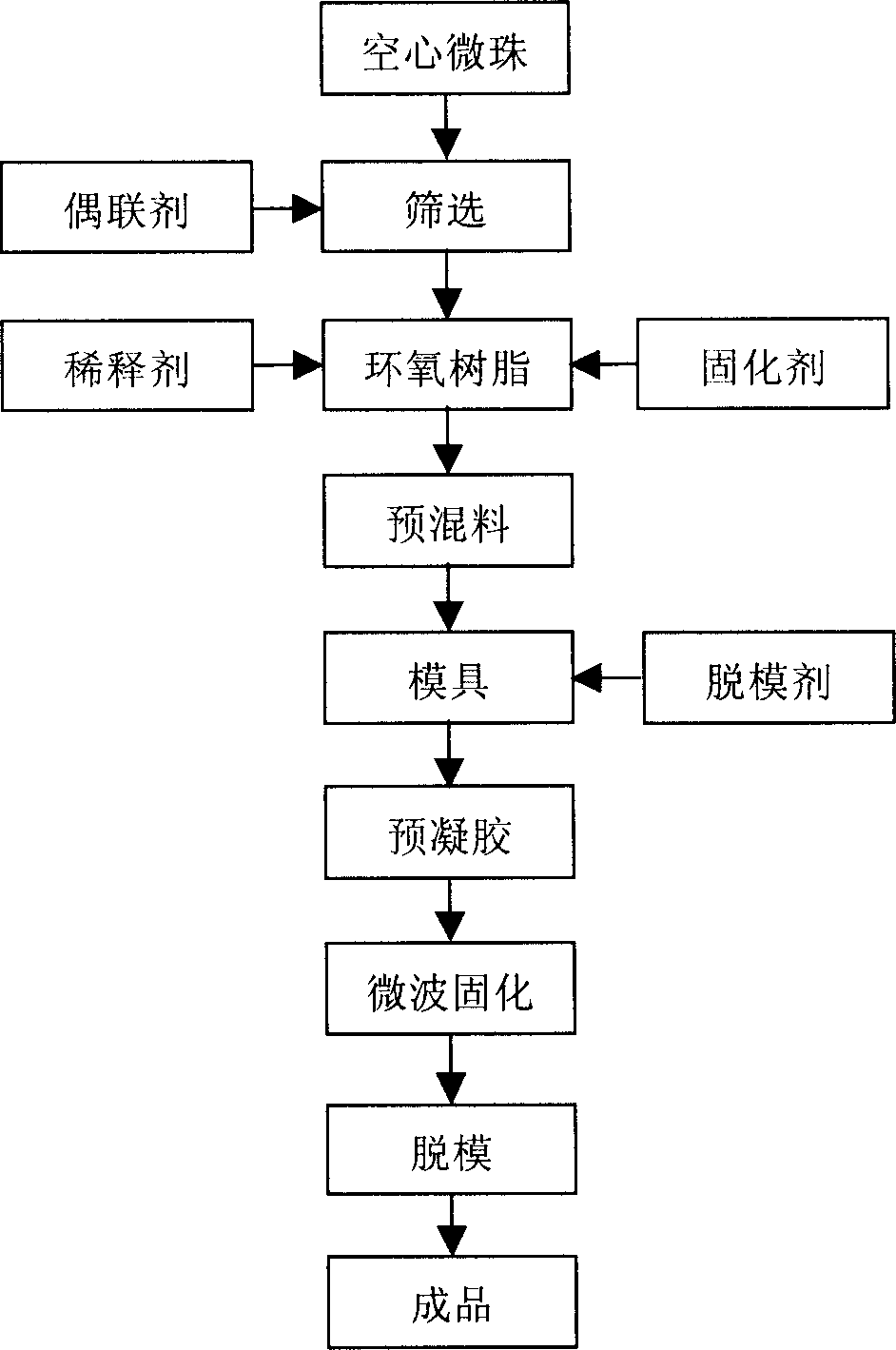

Method used

Image

Examples

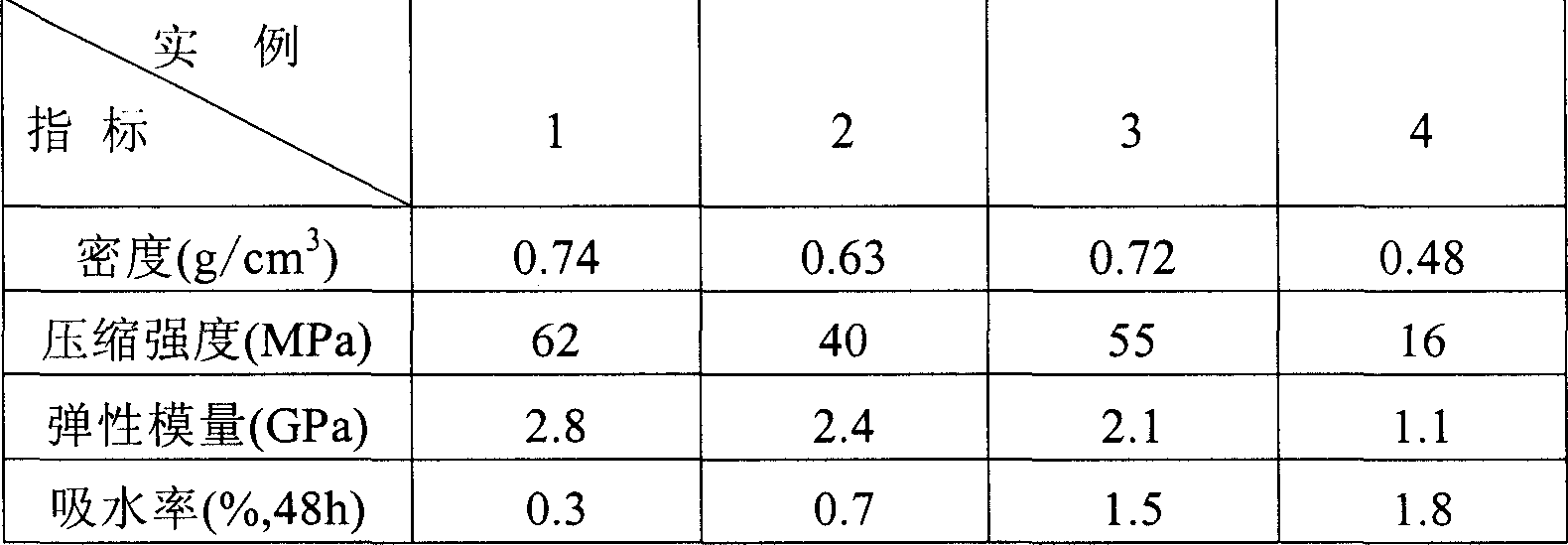

example 1

[0032] Example one. In parts by weight, the formulation of each component of the hollow microsphere reinforced epoxy resin composite material is as follows:

[0033] 100 parts of CYD-127, 35 parts of LHB-236, 10 parts of propylene oxide butyl ether, 7 parts of KH-550, 70 parts of hollow glass microspheres.

example 2

[0034] Example two. In parts by weight, the formulation of each component of the hollow microsphere reinforced epoxy resin composite material is as follows:

[0035] 100 parts of CYD-128, 38 parts of LHB-238, 15 parts of propylene oxide butyl ether, 9 parts of KH-550, 90 parts of hollow glass microspheres.

example 3

[0036] Example three. In parts by weight, the formulation of each component of the hollow microsphere reinforced epoxy resin composite material is as follows:

[0037] E-44 100 parts, 2-ethyl-4-methylimidazole 10 parts, propylene oxide butyl ether 15 parts and ethylene glycol diglycidyl ether 10 parts, KH-560 11 parts, hollow ceramic microspheres 110 parts .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com