Process of flowing multistage chemical thermo-dynamic for cleaning mud oil-containing

A technology for hot washing and cleaning area, applied in chemical instruments and methods, separation methods, sludge treatment, etc., can solve problems such as increasing power consumption, reducing stability, and increasing costs, reducing power consumption and improving adaptability. , the effect of easy material balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

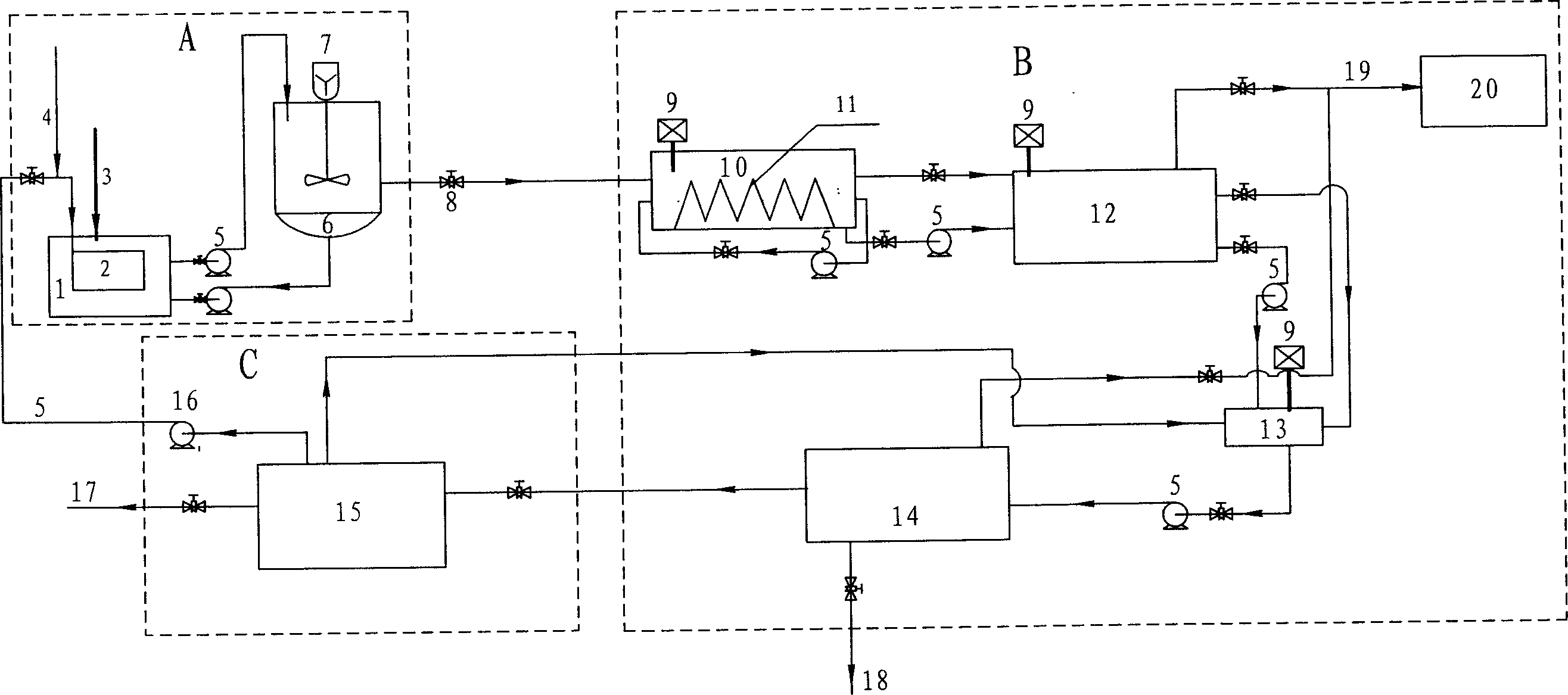

Method used

Image

Examples

Embodiment 1

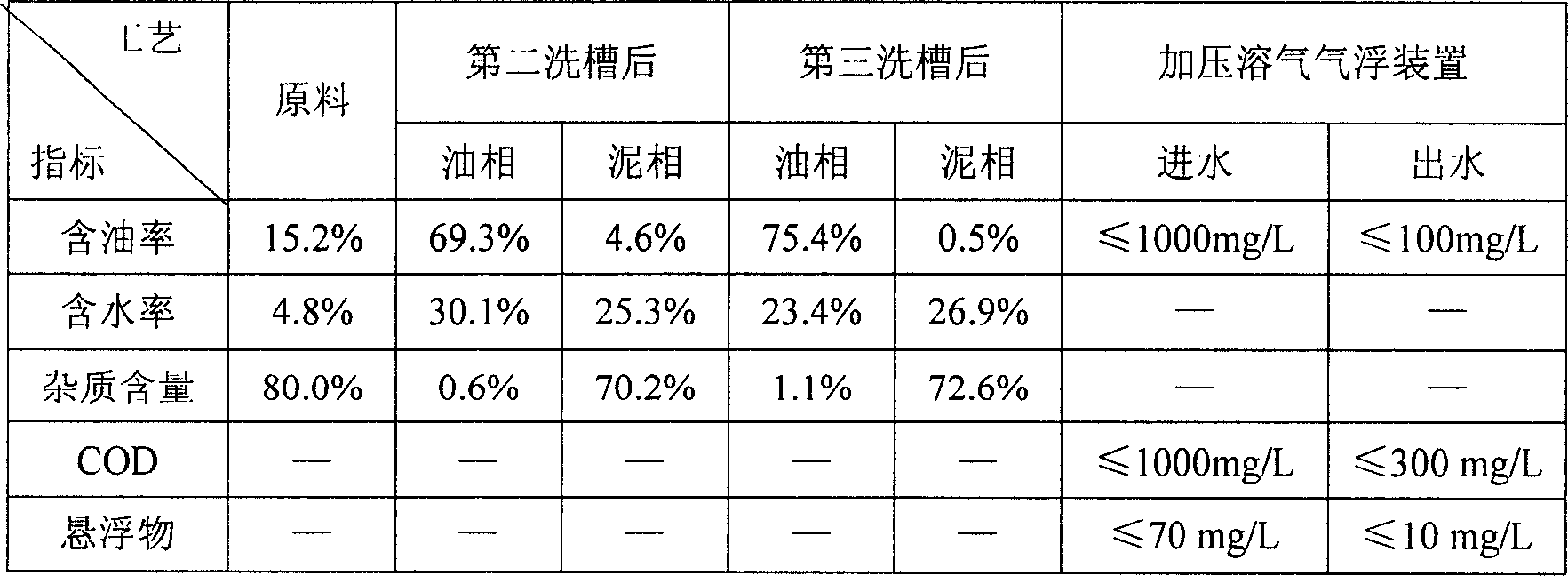

[0025] Floor sludge cleaning experiment

[0026] The ground oil sludge is taken from an oil refinery in Liaohe Oilfield. It is a black solid at room temperature and contains oil, sediment, water, etc.

[0027] Take 100g of ground oil sludge with a moisture content of 4.8%, an oil content of 15.22%, and an ash content of 79.98% (average value) in a 2-liter beaker, add 500ml of warm water, adjust the pH value to 9, stir vigorously for 10 minutes, and place it in a water bath at 60°C for 30 minutes , put it into a thermal insulation bag, scrape off the upper layer of slick oil, adjust the pH value of the water phase to 7, add 100g / l AEO-94ml to it, stir for 5 minutes, and then let it stand for 30 minutes. Scrape out the upper layer of slick oil and measure its moisture and impurity content after the first scraping is mixed, and measure the oil content of the bottom mud.

[0028] Upper oil slick: 21.55g, moisture content 38.12%, oil content 61.07%, impurity 0.81%

[0029] Bottom...

Embodiment 2

[0032] Scum cleaning experiment

[0033] The scum comes from a waste oil recycling company, which is the scum produced in the process of oil refining and sewage purification. It is liquid at room temperature, containing petroleum, emulsion, water and a small amount of chemical substances.

[0034] Take 100g of scum with a moisture content of 70.04%, oil content of 8.29%, and ash content of 21.67% (average value) in a 2-liter beaker, add 300ml of warm water, adjust the pH value to 5, add demulsifier DL-100 200ppm, stir vigorously for 5 minutes, and then place After standing in a water bath at 60°C for 30 minutes, put it in a heat preservation bag, scrape off the upper layer of slick oil and measure its impurity content, adjust the pH value of the water phase=7, add 10g / L polyiron 5ml, 1g / L CPAM (molecular weight 6 million) 2ml, stirred for 5 minutes and then allowed to stand for 30 minutes. Scrape out the upper layer of slick oil to measure its impurity content, and measure th...

Embodiment 3

[0039] Tank Bottom Mud Cleaning Experiment

[0040] The tank bottom sludge comes from the oil garbage cleaned from the bottom of the ship bilge and oil storage tank by a waste oil recycling company. It is dark brown semi-solid at room temperature, containing oil, sand, rust, water and impurities.

[0041] Take 100g tank bottom mud with moisture content of 7.70%, oil content of 78.75%, ash content of 13.55% (average value) in a 2-liter beaker, add 800ml of warm water, add demulsifier DL-4020 100ppm, adjust the pH value to 11, stir vigorously for 5 minutes and place After standing in a water bath at 60°C for 30 minutes, put it into a thermal insulation bag, scrape off the upper layer of slick oil and measure its impurity content, adjust the pH value of the water phase to 7, add 100g / L AEO-9 1ml to it, stir for 5 minutes and then let it stand. Set for 30min. Scrape out the upper layer of slick oil to measure its impurity content, and measure the oil content of the bottom mud. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com