Method for controlling carbon supplement culturing of microalgae through pH value feedback

A feedback control and microalgae technology, applied in biochemical equipment and methods, tissue cell/virus culture devices, single-cell algae, etc., can solve problems such as interference with pH control, poor carbon supplementation, and difficult control. Achieve the effects of eliminating mutual interference, shortening the production cycle, and facilitating implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

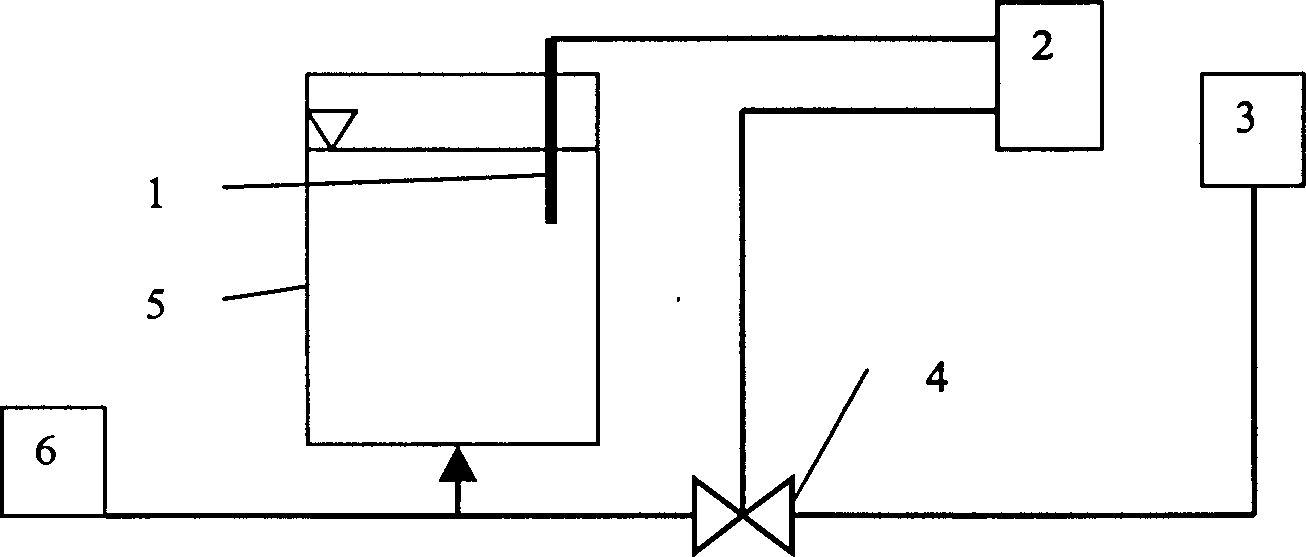

[0031] See figure 1 , wherein the pH sensor 1 is a commercially available steam sterilizable pH electrode, the control device 2 is a pH meter with switch control, CO 2 The gas source device 3 is provided by a steel cylinder, the actuator 4 is a two-position normally closed solenoid valve (diameter 8 mm), and the microalgae cultivation device 5 is a 20-liter air-lift photobioreactor (Chinese patent ZL99213569.9). The supply device 6 is an air compressor (supplies air). Necessary flow meters, filters and valves are also installed in the pipeline. Haematococcus pluvialis (Haematococcus pluvialis-F712, freshwater algae species bank of the Type Culture Collection Committee of the Chinese Academy of Sciences) was cultivated in the 20-liter airlift photobioreactor.

[0032] The medium was SM medium prepared with ordinary tap water.

[0033] The medium in the airlift photobioreactor was boiled for 20 minutes to sterilize by introducing hot steam, and after cooling, the seed solutio...

Embodiment 2

[0036] The equipment used is the same as in Example 1. Dunaliella salina (Dunaliella salina 1009, Institute of Salt Manufacturing, Ministry of Light Industry, Tanggu, Tianjin) was cultivated in a reactor.

[0037] The medium is ASP prepared in distilled water 2 Culture medium (remove the vitamin solution and buffer). In order to avoid precipitation when preparing the medium, ASP 2 MgSO in medium 4 and CaCl 2 Dissolve separately first, then add the two ingredients after the other ingredients have dissolved and diluted with sufficient distilled water. NaCl was then added to a final concentration of 12%.

[0038] The culture medium is not sterilized, and the seed solution is directly inserted through the inoculation port of the reactor, and the volume of the culture medium in the reactor is 16 liters. The initial algae cell density was 8×10 4 cells / ml. The temperature in the reactor was controlled at 30±0.5°C. Illumination is provided by 15 36W fluorescent lamps on the p...

Embodiment 3

[0041] The equipment used is the same as in Example 1. Spirulina platensis (Spirulina Platensis, 439, Freshwater Algae Species Bank of Type Culture Collection Committee, Chinese Academy of Sciences) was cultivated in the reactor.

[0042] The medium was Zarrouk's medium prepared with deionized water.

[0043] Feed hot steam to make the culture medium boil for 20 minutes to sterilize, and after cooling, insert the seed solution through the inoculation port of the reactor, and the volume of the culture medium in the reactor is 16 liters. The initial algal cell concentration was 0.02g / L. The temperature in the reactor was controlled at 30±1°C. The light intensity is 127 μmol photon m -2 the s -1 . On the control instrument 2, the pH value of the culture solution was set at 9.4, the flow rate of air was 5.0 L / min, and the flow rate of carbon dioxide was 70 mL / min (the solenoid valve was open) or 0 (the solenoid valve was closed). During the cultivation process, the instrume...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com