Method for integrating technique of damp drying sludge with technique for fermenting acrobic compost in high temperature

An aerobic composting and technology integration technology, applied in the fields of sewage/sludge fertilizer, dewatering/drying/concentrated sludge treatment, organic fertilizer, etc. Large and other problems, to achieve the effect of high degree of automation, low air demand, and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

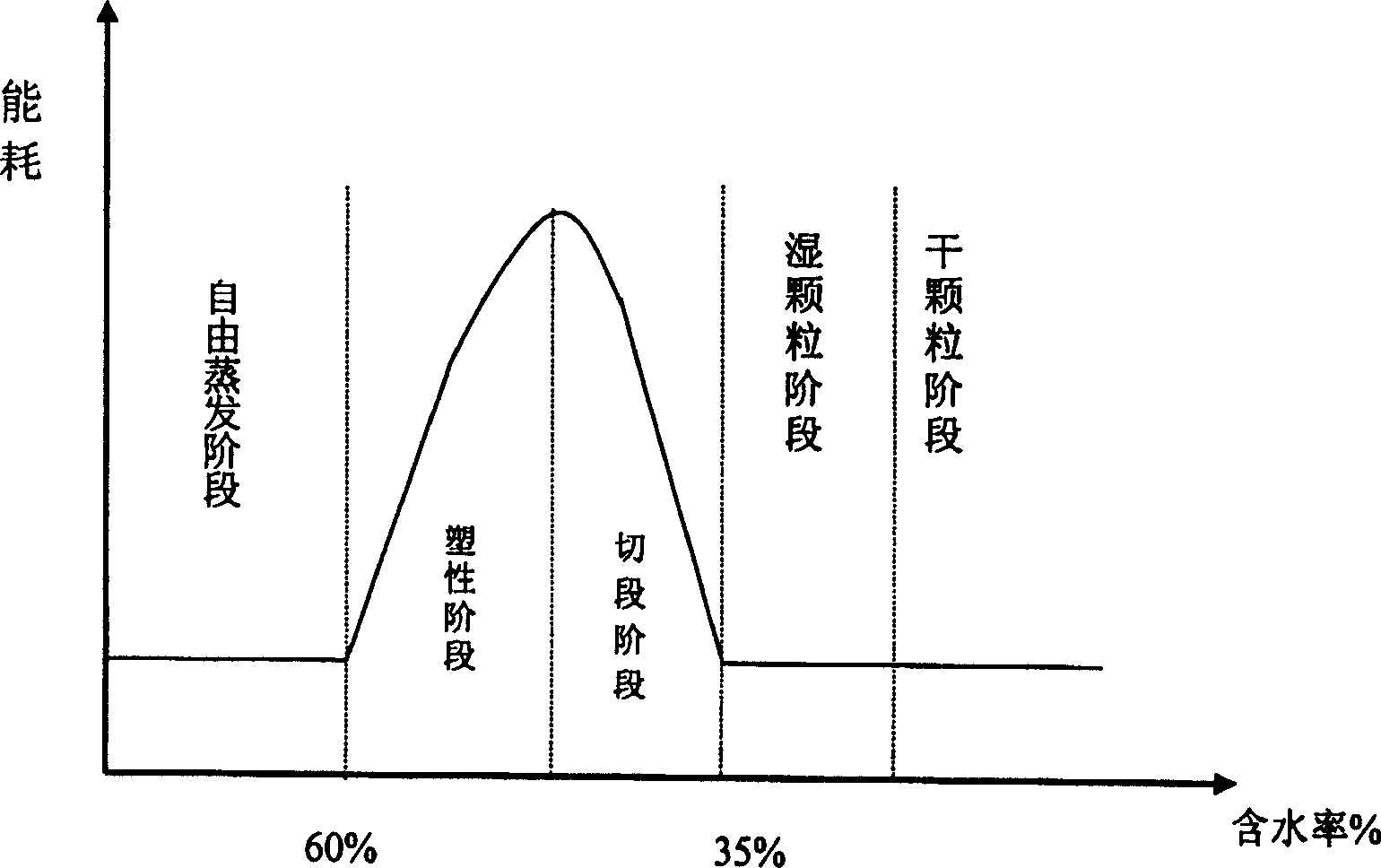

[0025] Over the years, experts at home and abroad have done a lot of analysis, research and experiments in this area. Among them, the energy consumed in the sludge drying process with different water contents was compared and analyzed, and the energy consumption of sludge drying and the water content of sludge were obtained. rate curve, see figure 1 .

[0026] Depend on figure 1 It can be seen from the relationship curve of the dewatered sludge that the dewatered sludge is heated and dried to reduce the water content from 80% to 60%. The energy consumption is also small, and the energy consumption of these two stages is basically close to the theoretical value; the sludge has a moisture content between 35% and 60%, which is the plastic stage of the sludge, and the fluid characteristics of the sludge at this stage are similar to glue, colloidal, It is viscous and difficult to handle. It consumes a sharp increase in drying energy and is difficult to dry. According to the abov...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap