FBE pnenolic aldehyde modified epoxy powder coating and its preparation method

A phenolic modified epoxy and powder coating technology, applied in powder coatings, epoxy resin coatings, coatings, etc., can solve the problems of low cross-linking degree, the anti-corrosion coating is difficult to meet the requirements of heavy anti-corrosion, and the leveling is poor. Achieve the effect of strong adhesion, good construction technology and excellent chemical resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

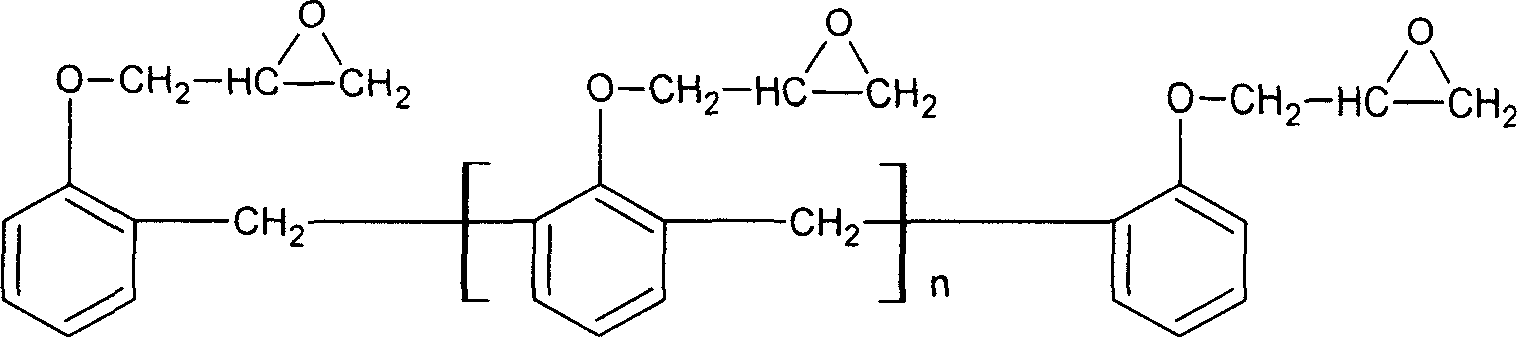

Image

Examples

Embodiment 1

[0030] This embodiment demonstrates the preparation method of the FBE phenolic modified epoxy heavy-duty anti-corrosion powder coating of the present invention.

[0031] Add 50.00kg of phenolic modified epoxy resin, 10.00kg of curing agent, and 2.00kg of leveling agent into a high-speed mixer and mix for 2 minutes, add 0.28kg of degasser, 0.02kg of curing accelerator, 0.50kg of medium chrome yellow, and phthalocyanine Blue 0.05kg, titanium dioxide 2.50kg, precipitated barium sulfate 34.65kg, mixed at high speed for 3 minutes, the premixed material was added to the extruder to melt and extrude, the temperature of the feeding section was 88°C, the temperature of the melting section was 100°C, and the mixing section was 110°C. The material section is at 100°C, the speed of the extruder is controlled at 70rpm, and the tablet is pressed, cooled and crushed on the air-cooled crawler-type tablet crusher. The thickness of the tablet is 2mm, and it is broken into flakes of 5-10mm. After...

Embodiment 2

[0033] The formula of FBE phenolic modified epoxy heavy-duty anti-corrosion powder coating is as follows:

[0034] Phenolic modified epoxy resin 37.50kg

[0035] E-12 epoxy resin 12.50kg

[0036] Curing agent 12.50kg

[0037] Leveling agent 1.00kg

[0038] Degasser 0.30kg

[0039] Curing accelerator 0.03kg

[0040] Medium chrome yellow 0.50kg

[0041] Phthalocyanine blue 0.05kg

[0042] Titanium dioxide 2.50kg

[0043] Precipitated barium sulfate 33.12kg

[0044] Product particle size control: 150μm sieve powder ≤ 3%, 250μm sieve powder ≤ 0.2%

Embodiment 3

[0046] The formula of FBE phenolic modified epoxy heavy-duty anti-corrosion powder coating is as follows:

[0047] Phenolic modified epoxy resin 25.00kg

[0048] E-12 epoxy resin 25.00kg

[0049] Curing agent 15.00kg

[0050] Leveling agent 1.70kg

[0051] Degasser 0.20kg

[0052] Curing accelerator 0.05kg

[0053] Medium chrome yellow 0.50kg

[0054] Phthalocyanine blue 0.05kg

[0055] Titanium dioxide 2.50kg

[0056] Precipitated barium sulfate 30.00kg

[0057] Product particle size control: 150μm sieve powder ≤ 3%, 250μm sieve powder ≤ 0.2%

[0058]The technical index that the FBE phenolic modified epoxy heavy-duty anticorrosion powder coating that makes by embodiment can reach:

[0059] a. Properties of anti-corrosion epoxy powder

[0060] Item Quality Index

[0061] Appearance Uniform color, no agglomeration

[0062] Curing time (180°C) / min ≤5

[0063] Curing time (180℃) / s ≤90

[0064] Adhesion / level ≤2

[0065] Non-volatile content (%) ≥99.4

[0066] Part...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curing time | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Volume resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com