L-ornidazole prepn

A preparation technology of L-ornidazole, which is applied in the field of preparation of nitroimidazole antibiotics L-ornidazole, can solve the problems of high toxicity and poor activity of ornidazole racemate, and achieve long half-life, no special toxicity, The effect of good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

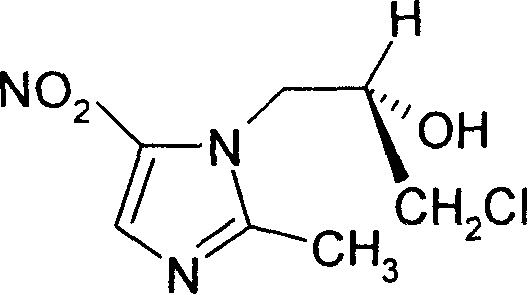

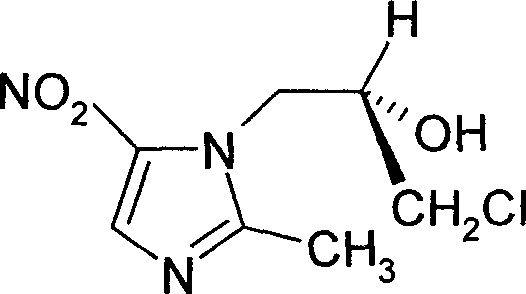

Image

Examples

Embodiment 1

[0018] Make 1000 L-ornidazole tablets with the raw materials in the following weight ratio, and the tablet weight is 435mg

[0019] Levonidazole 250g

[0020] Pregelatinized starch 50g

[0021] Microcrystalline Cellulose 100g

[0022] 3% HPMC 40% ethanol solution appropriate amount

[0023] Sodium carboxymethyl starch 30g

[0025] Preparation Process:

[0026] 1. Raw materials and auxiliary materials of L-ornidazole are pulverized separately and passed through a 100-mesh sieve.

[0027] 2. Take L-ornidazole, pregelatinized starch, and microcrystalline cellulose and mix well, use 3% HPMC 40% ethanol solution to make soft material, granulate, and granulate after drying.

[0028] 3. Add sodium carboxymethyl starch and magnesium stearate, mix well, and press into tablets.

Embodiment 2

[0030] 1. Prepare 6% ethanol solution of Opadry enteric coating solution;

[0031] 2. Take the plain tablet obtained in Example 1 and pour it into a coating pan for coating to obtain L-ornidazole enteric-coated tablet. Coating powder relative to tablet core weight gain: 4.0-5.0%.

Embodiment 3

[0033] Prepare 1000 L-ornidazole tablets with the raw materials in the following weight ratio, and the tablet weight is 230 mg.

[0034] Levonidazole 125g

[0035] 30g pregelatinized starch

[0036] Microcrystalline Cellulose 50g

[0037] 3% HPMC 40% ethanol solution appropriate amount

[0038] Sodium carboxymethyl starch 20g

[0040] Preparation Process:

[0041] 1. Separately pulverize the L-ornidazole raw material and auxiliary materials, and pass through a 100-mesh sieve.

[0042] 2. Take L-ornidazole, pregelatinized starch, and microcrystalline cellulose and mix well, use 3% HPMC 40% ethanol solution to make soft material, granulate, and granulate after drying.

[0043] 3. Add sodium carboxymethyl starch and magnesium stearate, mix well, and press into tablets.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sheet weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com