High vacuum in-situ two-step refining process for high purity material

A high-vacuum, in-situ technology, applied to the improvement of process efficiency, furnace type, furnace, etc., can solve the problems of device performance degradation, influence on purification effect, lack of purification means, etc., to reduce pollution, reduce impact, reduce reaction and composite effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

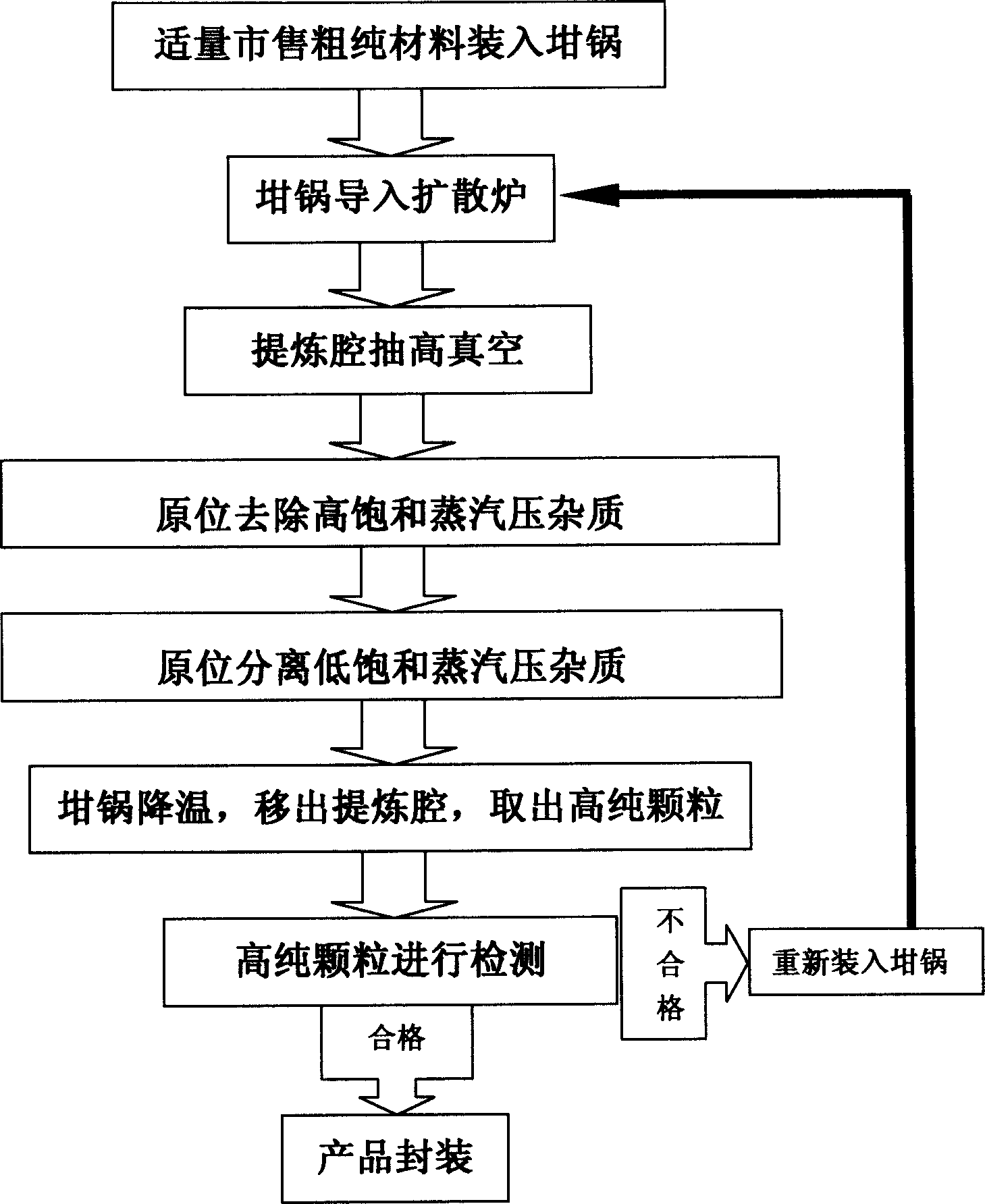

[0032] Example 1 High-vacuum in-situ two-step refining method for high-purity magnesium metal

[0033] Such as figure 1 As shown in the process flow diagram of the present invention, the concrete steps of utilizing high vacuum in-situ two-step refining method to extract high-purity metallic magnesium are as follows:

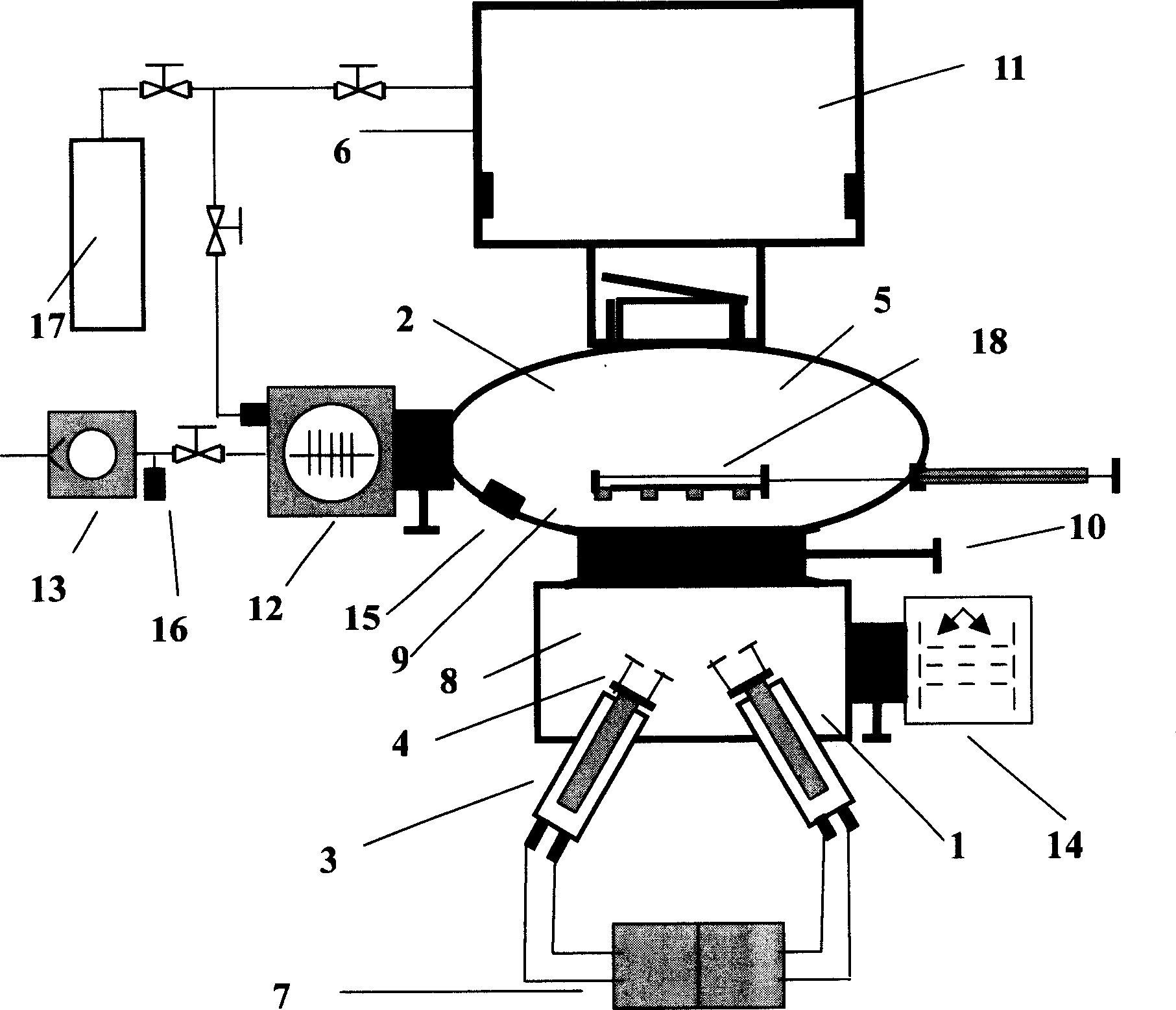

[0034] 1) Select high-purity argon as the protective gas for purifying magnesium metal in the high-vacuum in-situ refining device;

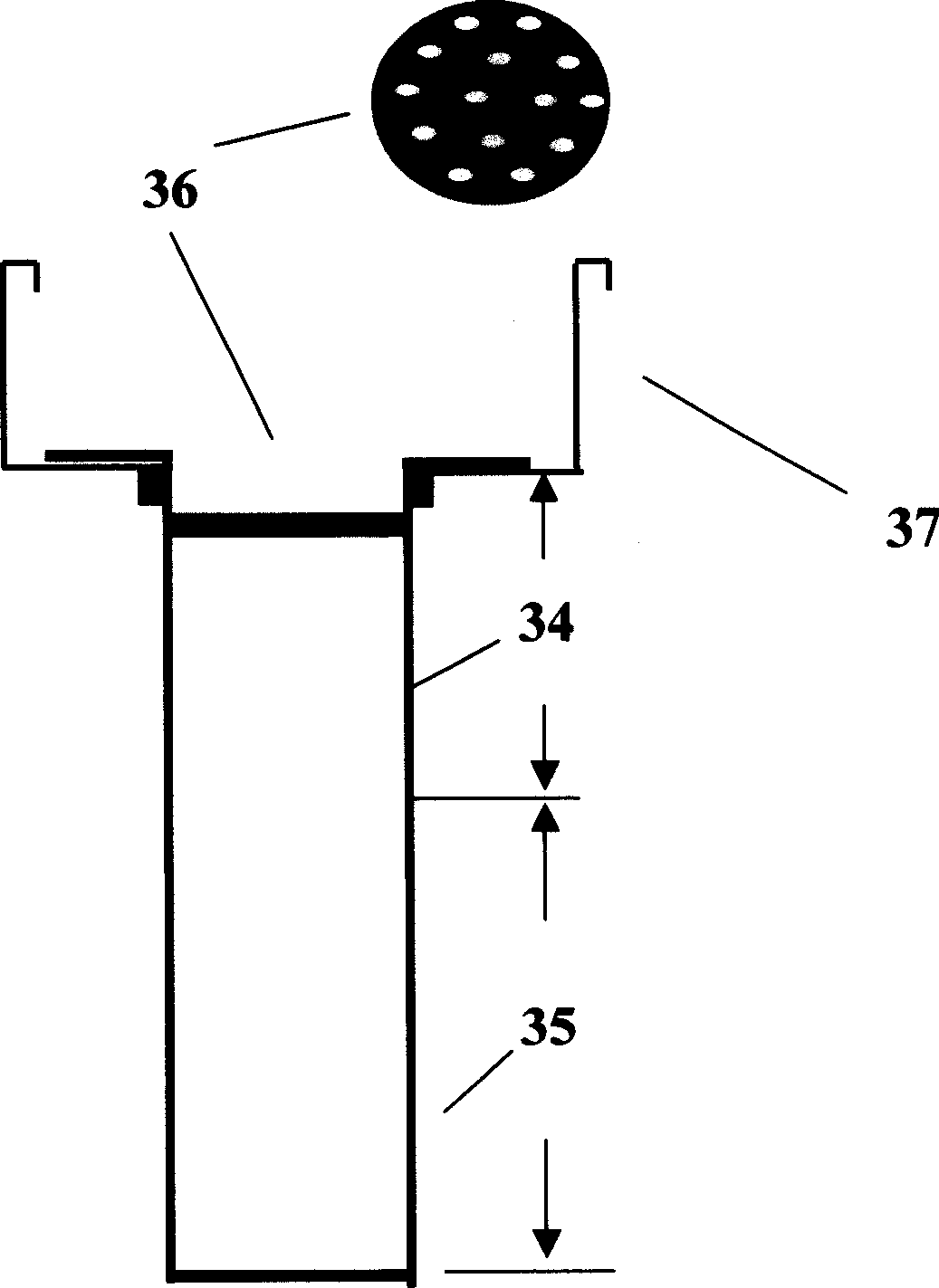

[0035] 2) if Figure 4 The shown crucible is divided into upper and lower parts 34, 35, and its positions correspond to Figure 4 The upper and lower heating wires 22, 23 of the shown diffusion furnace, that is, the upper heating wire 22 of the diffusion furnace heats the upper part 34 of the crucible, and the lower heating wire 23 heats the lower part 35 of the crucible. Metal magnesium (99.95%) is packed into the crucible so that it just fills up the bottom 35 of the crucible;

[0036] 3) Lead the crucible containing crude and...

Embodiment 2

[0048] Example 2 High-vacuum in-situ two-step refining method for high-purity metallic calcium

[0049] Such as figure 1 As shown in the process flow diagram of the present invention, the concrete steps of utilizing high vacuum in-situ two-step refining method to extract high-purity metallic calcium are as follows:

[0050] 1) High-purity argon is selected as the protective gas for purifying metallic calcium in the high-vacuum in-situ refining device;

[0051] 2) if Figure 4 The shown crucible is divided into upper and lower parts 34, 35, and its positions correspond to Figure 4 The upper and lower heating wires 22, 23 of the shown diffusion furnace, that is, the upper heating wire 22 of the diffusion furnace heats the upper part 34 of the crucible, and the lower heating wire 23 heats the lower part 35 of the crucible. Calcium metal (99.5%) is packed into the crucible so that it just fills up the bottom 35 of the crucible;

[0052] 3) Lead the crucible filled with crude ...

Embodiment 3

[0061] Embodiment 3 The high vacuum in-situ two-step refining method of high-purity sodium hydroxide

[0062] Such as figure 1 Shown process flow diagram of the present invention, utilizes high vacuum in-situ two-step refining method to refine the concrete steps of high-purity sodium hydroxide as follows:

[0063] 1) Select high-purity argon as the protective gas for purifying sodium hydroxide in the high-vacuum in-situ refining device;

[0064] 2) if Figure 4 The shown crucible is divided into upper and lower parts 34, 35, and its positions correspond to Figure 4 The upper and lower heating wires 22, 23 of the shown diffusion furnace, that is, the upper heating wire 22 of the diffusion furnace heats the upper part 34 of the crucible, and the lower heating wire 23 heats the lower part 35 of the crucible. Sodium hydroxide (97%) is packed into the crucible so that it just fills up the bottom 35 of the crucible;

[0065] 3) Lead the crucible with crude sodium hydroxide into...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com