Method for producing aromatic carboxylic acid

A kind of technology of aromatic carboxylic acid and aromatic compound, applied in the field of preparation of aromatic carboxylic acid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Hereinafter, the present invention will be described in detail.

[0027] Examples of alkylaromatic compounds used in the present invention include alkylbenzenes and alkylnaphthalenes, such as monoalkane Benzene, dialkylbenzene or trialkylbenzene, also includes alkylbenzene and alkylnaphthalene whose alkyl group has been oxidized.

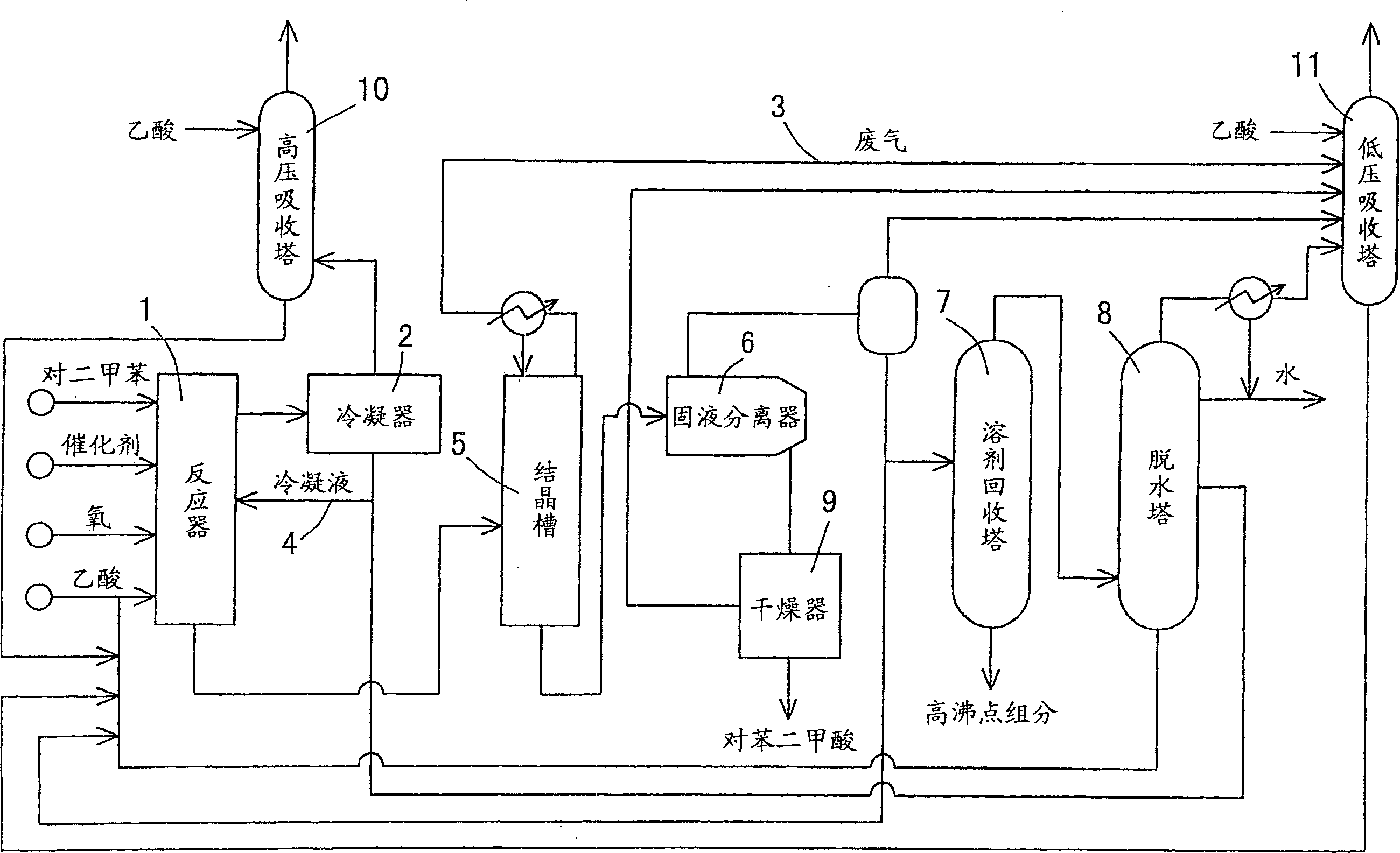

[0028] In addition, the method for preparing aromatic carboxylic acid adopted in the present invention typically includes the following steps:

[0029] (i) an oxidation reaction step for subjecting an alkylaromatic compound to a liquid-phase oxidation reaction in the presence of a catalyst containing cobalt, manganese and bromine in an acetic acid solvent to form a slurry containing an aromatic carboxylic acid;

[0030] (ii) a crystallization step for crystallizing the aromatic carboxylic acid dissolved in the mother liquor of the resulting slurry;

[0031] (iii) a solid-liquid separation step for solid-liquid separation of the aromatic car...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com