Pure ursine fat, and its prepn. method

A seal oil and esterification technology, applied in the field of purifying seal oil and its preparation, can solve the problems of low content, sample damage, environmental pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0138] 1. Esterification treatment of seal oil:

[0139] Take 500ml of seal oil, mix it with 500ml of 0.5mol / L sodium ethoxide containing 0.001% BHT, add glacial acetic acid to adjust the pH value to about 6.5, and obtain ethylated seal oil.

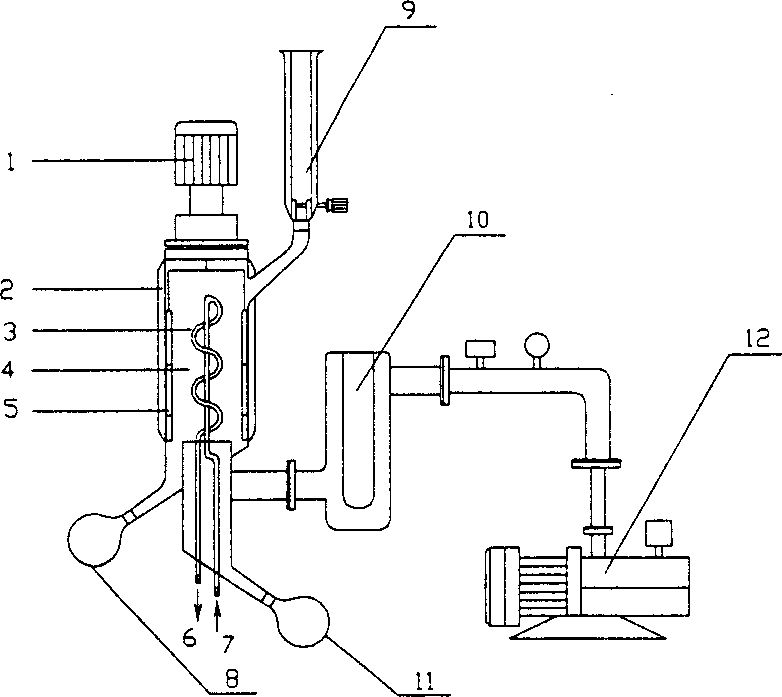

[0140] 2. Molecular distillation

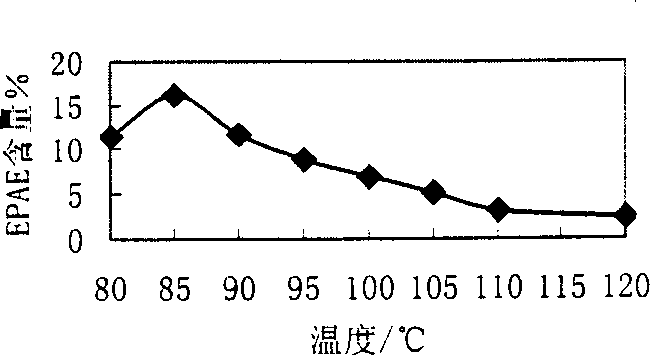

[0141] a) Degassing: The material is preheated at 50°C and enters the molecular distillation device, the feed rate is 650ml / h, the distillation temperature is 80°C, the absolute pressure of the system is 0.050mbar, the speed of the wiper rotor is 110rpm, and the polyene fatty acid ethyl ester enters the heavy component ,

[0142] b) The first step of separation: take the heavy component from the previous step and sample distillation, preheat at 60°C, feed rate 90ml / h, distill at 60°C, system absolute pressure 0.001mbar, wiper rotor speed 100rpm; re-distill four times under the same conditions Second-rate;

[0143] c) The second step of separation: take the heavy component from the previous step, preh...

Embodiment 2

[0146] 1. Esterification treatment of seal oil:

[0147] Take 500ml of seal oil, mix it with 500ml of potassium ethylate containing 0.5mol / L of 0.003% BHT, add glacial acetic acid to adjust the pH value to about 7.1, and obtain ethylated seal oil.

[0148] 2. Molecular distillation

[0149] a) Degassing: The material is preheated at 60°C and enters the molecular distillation device, the feed rate is 720ml / h, the distillation temperature is 80°C, the absolute pressure of the system is 0.040mbar, the speed of the wiper rotor is 140rpm, and the polyene fatty acid ethyl ester enters the heavy component ;

[0150] b) The first step of separation: take the heavy component from the previous step and sample distillation, preheat at 60°C, feed rate 210ml / h, distill at 80°C, system absolute pressure 0.005mbar, wiper rotor speed 140rpm, take the heavy component and re-inject, The distillation temperature was changed to 85°C, the feed rate was 90ml / h, and the others were the same as abo...

Embodiment 3

[0154] 1. Esterification treatment of seal oil:

[0155] Take 500ml of seal oil, mix it with 500ml of potassium ethylate containing 0.7mol / L of 0.005% BHT, add glacial acetic acid to adjust the pH value to about 7.5, and obtain ethylated seal oil.

[0156] 2. Molecular distillation

[0157] a) Degassing: Preheat the material at 70°C and enter the molecular distillation device, the feed rate is 750ml / h, the distillation temperature is 80°C, the absolute pressure of the system is 0.060mbar, the speed of the wiper rotor is 170rpm, and the PUFAE enters the heavy component.

[0158] b) The first step of separation: take the heavy component from the previous step and sample distillation, preheat at 110°C, feed rate 900ml / h, distill at 110°C, system absolute pressure 0.03mbar, wiper rotor speed 300rpm; take the heavy component and re-inject , the conditions were the same as above and the distillation was repeated twice.

[0159] c) The second step of separation: take the heavy comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com