Production bacterial strain of abamectin with high yield and high secreation rate and new method of extracting AVM

A high-secretion rate bacterium and abamectin technology, applied in the direction of microorganism-based methods, biochemical equipment and methods, botany equipment and methods, etc., can solve problems such as poor taste, and achieve good health, The effect of reducing the dosage and reducing the cost of refining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

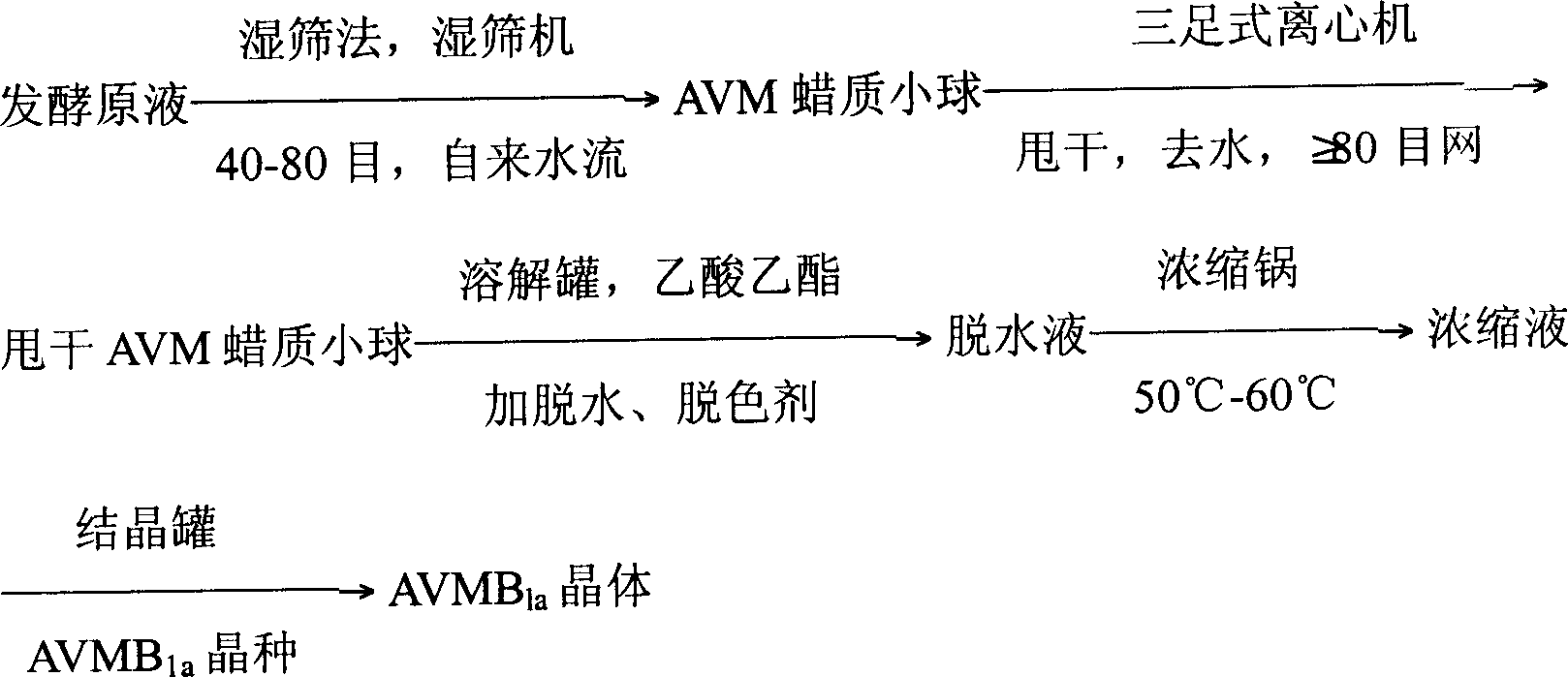

Method used

Image

Examples

Embodiment 1

[0088] Abamectin was produced by batch fermentation using Streptomyces avermitilis AVHF-31 strain.

[0089] The slant was prepared according to the formula of malt powder starch inorganic salt agar slant medium described above. After 3 days of pre-cultivation, if no bacteria growth was found, the AVHF-31 strain was inoculated. Cultivate in an incubator at 28°C for 5 days, harvest the spores after they mature, and store them in a refrigerator at 4°C for fermentation.

[0090] Prepare a 10L seed tank with a feeding factor of 65%. The ingredients of the seed medium are: 3% starch, 0.8% bean cake powder, 0.9% peanut cake powder, 0.45% yeast extract, 0.45% yeast powder, 0.3% corn steep liquor, 0.003% cobalt chloride, 0.06% defoamer, before disinfection Adjust the pH to 7.2 with sodium hydroxide solution. Steam sterilize at 121°C for 30 minutes, and inoculate the spore suspension of the AVHF-31 strain after the culture medium is cooled to 28°C. The amount of inoculation is to ino...

Embodiment 2

[0093] Abamectin was produced by batch fermentation using Streptomyces avermitilis AVHF-66 strain.

[0094] The slant was prepared according to the formula of malt powder starch inorganic salt agar slant medium described above. After 3 days of pre-cultivation, if no bacteria growth was found, the AVHF-66 strain was inoculated. Cultivate in a 27°C incubator for 7 days, collect the spores after they mature, and store them in a 4°C refrigerator for fermentation.

[0095] Prepare a 10L seed tank with a feeding factor of 65%. The ingredients of the seed medium are: 4% starch, 0.5% bean cake powder, 1.2% peanut cake powder, 0.3% active dry yeast powder, 0.5% corn steep liquor, 0.0015% cobalt chloride, 0.04% defoamer, and oxidized with hydrogen before disinfection Adjust the pH to 7.2 with sodium solution. Steam sterilize at 121°C for 30 minutes, and inoculate the spore suspension of AVHF-66 strain after the culture medium is cooled to 28°C. The amount of inoculum is to inoculate ...

Embodiment 3、4、5

[0098] Adopt exactly the same step as Example 1, just replace AVHF-31 bacterial strain with AVHF-27, AVHF-49 and AVHF-61 bacterial strain respectively and produce Abamectin by batch fermentation.

[0099] The yields of these three strains are shown in Table 1:

[0100] Example

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fermentation titer | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com