Process for manufacturing wind-up type liver tissue engineering stent

A liver tissue and engineering technology, applied in the field of manufacturing process of wrap-type liver tissue engineering scaffolds, can solve the problems of difficulty in providing continuous treatment, uncontrollable hole distribution, and inability to obtain multi-level microstructures, and achieve customized manufacturing. , the effect of large material exchange capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

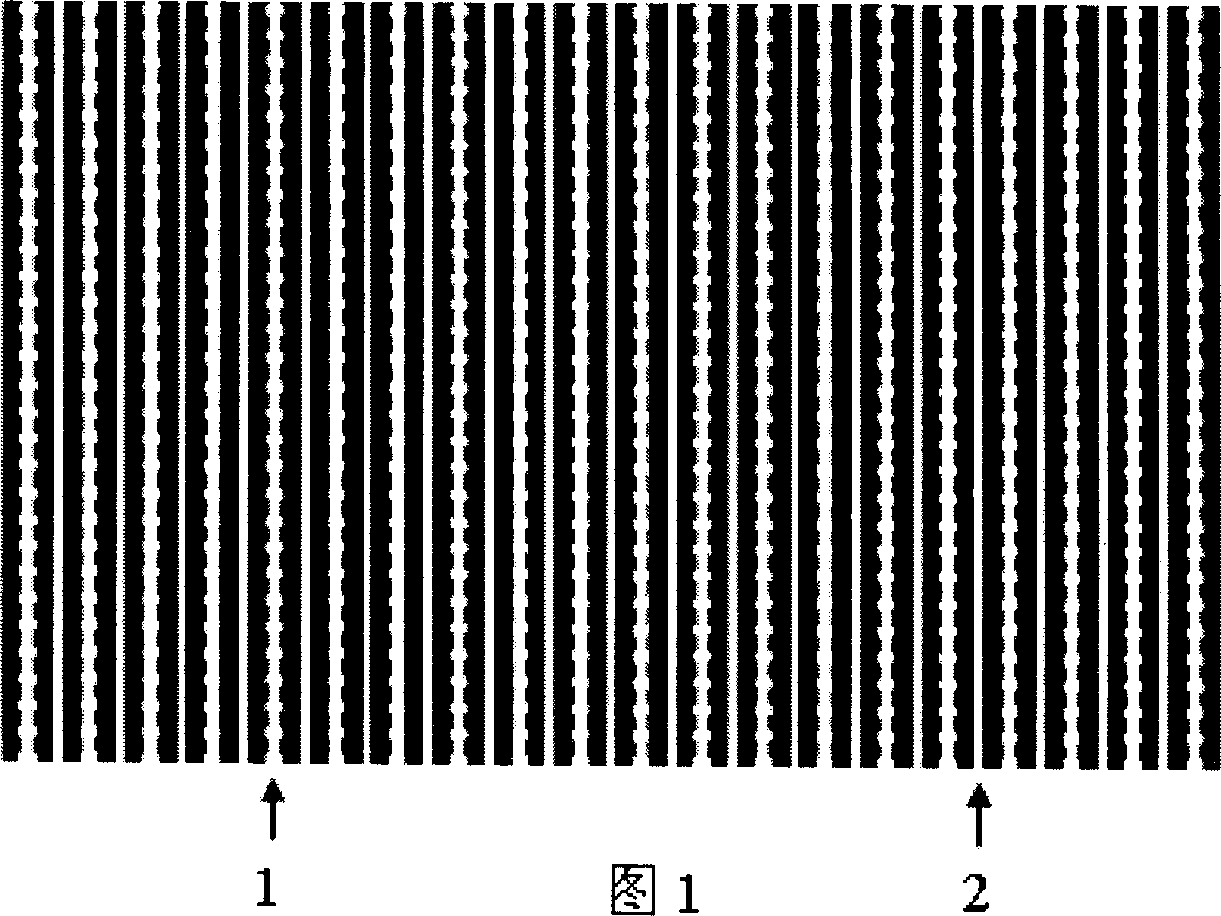

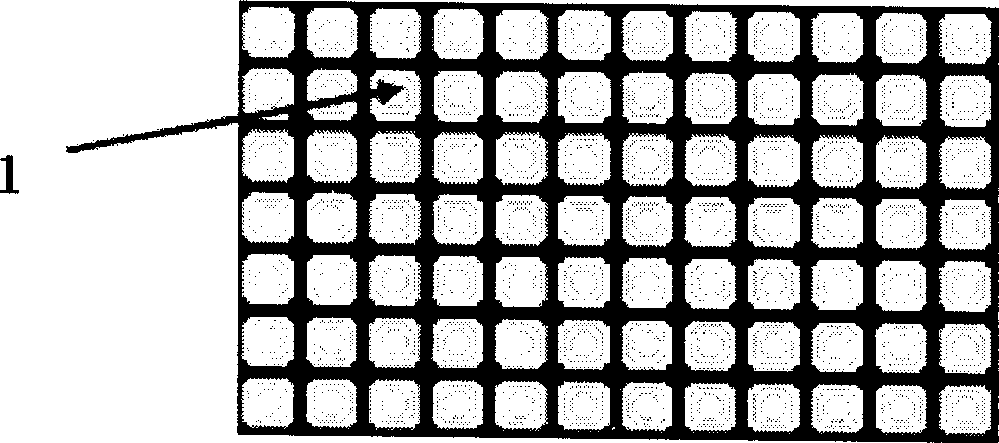

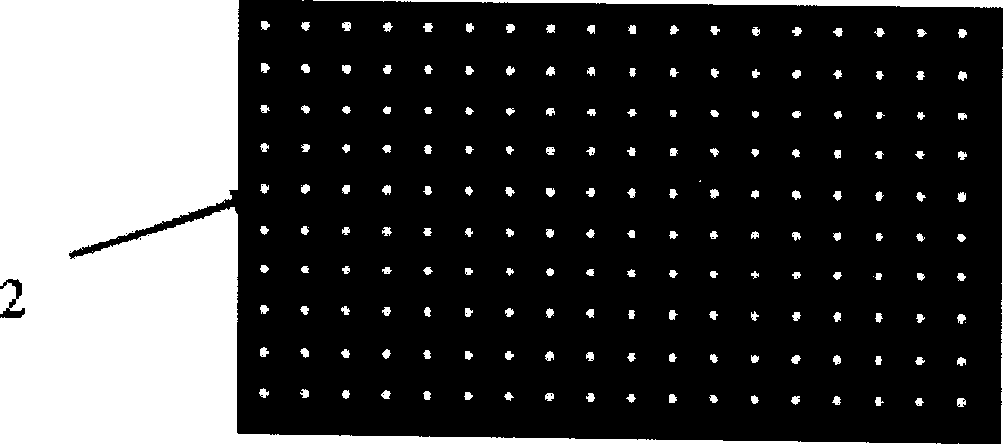

[0022] Referring to the accompanying drawings, according to the manufacturing process of the present invention, the microstructure of the natural liver tissue is simulated first, and the bionic design of the liver tissue engineering scaffold template including the vascular network system and the microstructure of liver cell holes is carried out. Convert the CAD model of the designed liver tissue engineering scaffold template into a rapid prototyping file format, and prepare a resin mold with rapid prototyping technology; use the resin mold to prepare a silicone rubber mold containing liver cell holes and vascular network microstructure through a micro-replication process ; For the semi-permeable membrane, the photolithographic slate technology can be used to manufacture the mask containing the fine hole structure, and the imprint mold can be formed by the mask photocuring process or photolithography process; the biological material with good biocompatibility and biodegradation c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com