Natural celery powder and its making process

A production method and technology of celery powder, applied in the direction of food science, etc., can solve the problems of poor solubility, coarse vegetable powder particles, poor product solubility, etc., and achieve the effects of being convenient for storage and export, improving hygienic standards, and good social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

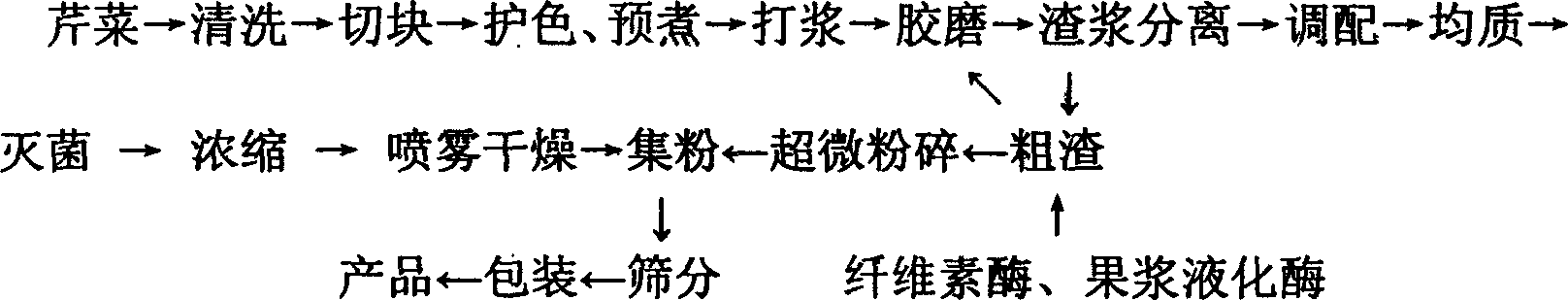

[0022] A kind of preparation method of health food celery powder, the feature of the present invention is to take fresh celery as main raw material, after cleaning, cutting, precooking for color protection, beating, rubber mill, secondary treatment, deployment, homogenization, sterilization, A kind of celery powder product obtained from the process of concentration, drying, powder collection, screening, packaging, and product storage, such as figure 1 shown.

[0023] Specific implementation steps: select pure natural fresh, mature, non-deteriorating, compact tissue, no insect erosion, no mildew, no pesticide pollution, fully wash with running water, pick out foreign objects such as residual branches and earth and stones, and do not leave any celery. sediment, so as not to affect product quality. After the water is drained, the net weight is 107kg, and cut into 1cm pieces. Pour the chopped celery into the jacketed pot, add 0.15kg of sodium sulfite and zinc acetate, adjust the...

Embodiment 2

[0026] The production process and method are the same as in Example 1, and the process conditions are changed to: pump 300 kg of celery pulp into a jacketed pot with a stirrer, add 15 kg of isomaltooligosaccharide and 45 kg of resistant starch, and stir evenly. Low-temperature vacuum concentration is adopted, and the concentration conditions are: 45° C., and the vacuum degree is 10 Kpa. After concentration, the solid content of the slurry reaches 57%. Use a spray dryer to dry, and the condition is: the pressure of the high pressure pump is controlled at 13.0MPa. Air inlet temperature: 175°C, exhaust air temperature: 85°C, 39kg of finished product is obtained after drying, and the moisture content of the material is 5%.

Embodiment 3

[0028] The production process and method are the same as in Example 1, and the process conditions are changed to: pump 300 kg of celery pulp into a jacketed pot with a stirrer, add 22.5 kg of isomaltooligosaccharide and 67.5 kg of resistant starch, and stir evenly. Vacuum cryogenic concentration may not be carried out. Use a spray dryer to dry, and the condition is: the pressure of the high pressure pump is controlled at 12.5MPa. Air inlet temperature: 170°C, exhaust air temperature: 80°C, 43kg of finished product is obtained after drying, and the moisture content of the material is 5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com