Application of four-needle zinc oxide whisker in photocatalysis to degrading indoor organic pollutant

A four-needle zinc oxide, organic pollutant technology, applied in the direction of metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, chemical/physical process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

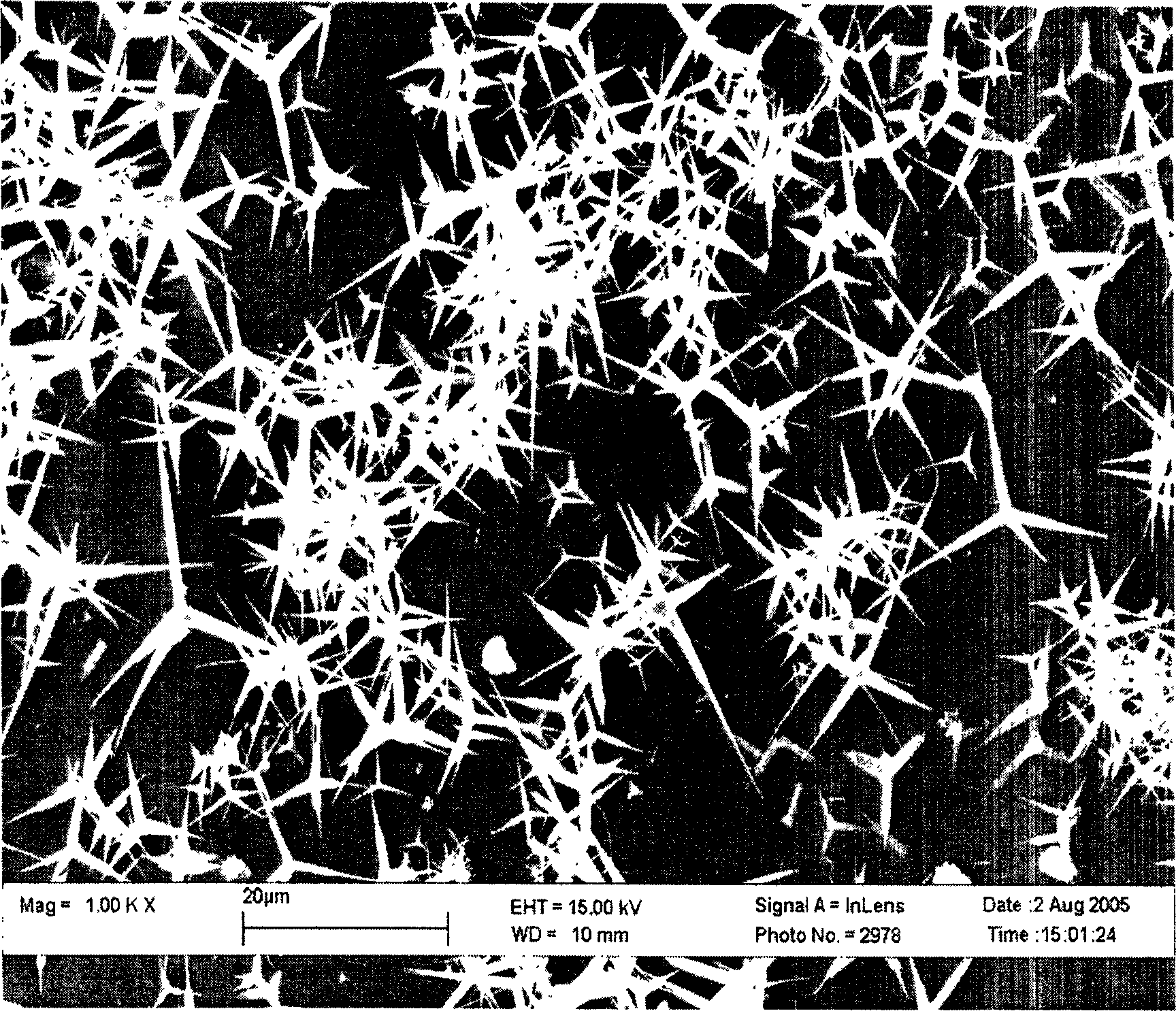

Image

Examples

Embodiment 1

[0018] Photocatalytic degradation of acetaldehyde gas using four-needle ZnO whiskers. Weigh 0.4g of self-made four-needle zinc oxide whiskers, add them into deionized water, stir gently, evenly coat on a glass (80mm×80mm in length×width), and dry in an oven at 70°C. Put the glass plate loaded with four-needle zinc oxide whiskers into a photocatalytic reactor with a volume of 500ml, seal it, inject about 3000ppm of acetaldehyde into it from an injection port, and let it stand for 12 hours. With a 300W xenon lamp as a light source, the reaction product was detected with a gas chromatograph GC-14B. After 4 hours of light, the concentration of acetaldehyde has not been measured; after 9 hours of light, 99.1% of acetaldehyde is mineralized into CO 2 . As a comparison, another 0.4g of nano-titanium dioxide (anatase phase: rutile phase is about 80:20, specific surface area 50.1m 2 / g), test under the same conditions, with nano-titanium dioxide as a catalyst, after 3 hours of light...

Embodiment 2

[0021] Formaldehyde gas was photocatalytically degraded by tetrapod ZnO whiskers. Weigh 1g of self-made four-needle-shaped zinc oxide whisker, mix it with water-based paint, spread it on a tile with a length × width of 80mm × 80mm, put it into a photocatalytic reactor with a volume of 500ml after drying, and seal it Inject about 800ppm of formaldehyde from an injection port and leave it for 12 hours. With a 300W xenon lamp as a light source, the reaction product was detected with a gas chromatograph GC-14B. After 2.5 hours of light exposure, no formaldehyde was detected. After calculation, the results show that 98.5% of formaldehyde is mineralized into CO 2 .

[0022] Using tetrapod ZnO whiskers and ZrO 2 , SiO 2 、Al 2 o 3 , CaO, MgO, CaCO 3 , mica, zeolite, activated carbon, lithopone, resin, metal powder, organic particles, coatings, chalk, etc., still have a certain photocatalytic activity, and the degradation efficiency is between 18 and 99.9% (according to the out...

Embodiment 3

[0024] Photocatalytic degradation of toluene gas using tetrapod ZnO whiskers. Select 0.2-30 micron glass fiber filaments and four-needle-shaped zinc oxide whiskers to mix in a weight ratio of 1:0.05-5 (weight ratio), and weave them into glass fiber cloth and glass fiber particulate filter core. Lining glass fiber cloth on the inner wall of a tubular photocatalytic reactor, placing an 18W black light tube in the middle of the tubular photocatalytic reactor, putting glass fiber particle filter elements at both ends, and installing a small blower at one end, In order to blow benzene-containing air into the reactor. Then put the whole tubular photocatalytic reactor into an airtight container, and inject the toluene with a concentration of 10mg / m 3 air. Gas degradation products were determined by Agilent gas chromatography-mass spectrometry (GC / MS-G2589A). After turning on the blower for 20 minutes, start to turn on the black light, and keep timing and sampling. After about 6 ho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com