Solid phase polymerization process for preparing ethylene telephthalate and aromatic diamine copolymer

A polyethylene terephthalate and aromatic binary technology, which is applied in the field of aromatic diamine copolymers, can solve the problems of expensive nucleating agents, poor dimensional stability, and slow crystallization speed. easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

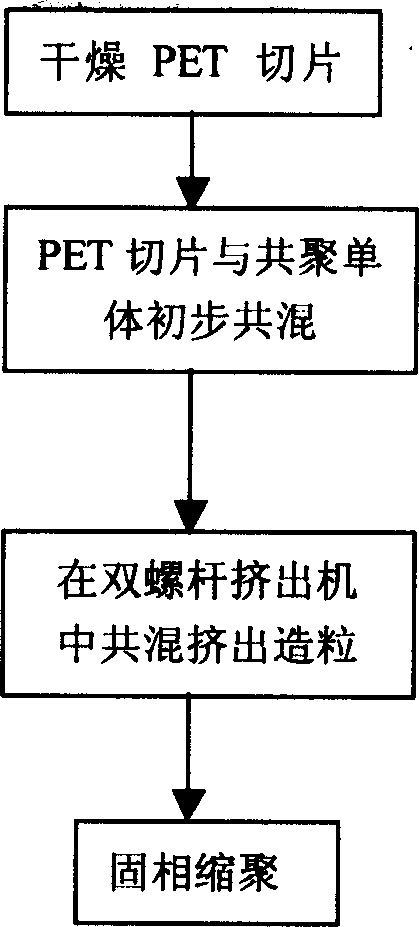

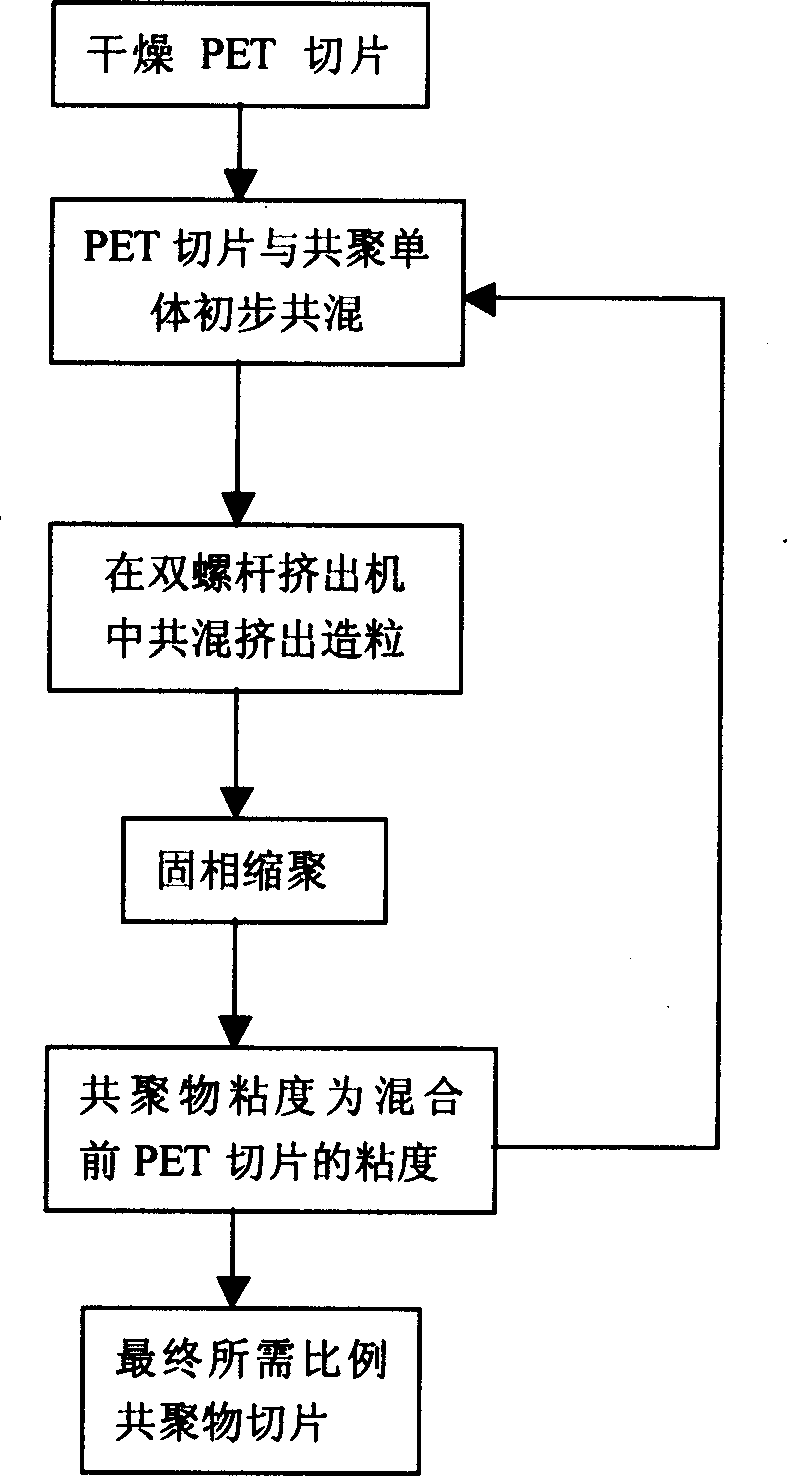

Method used

Image

Examples

Embodiment 1

[0031] The synthesis of embodiment 1 PET-DDS (5mol%) copolymer

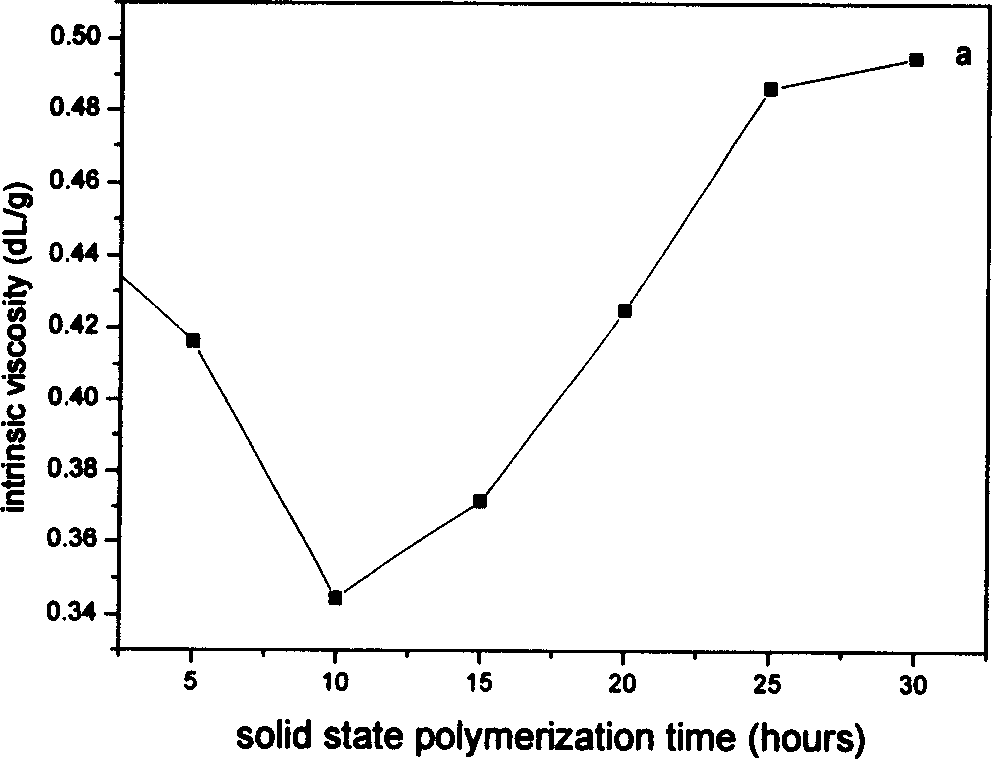

[0032]Dry the PET slices in an ordinary oven at 110°C for one day, and mix them with DDS for later use. The temperature of each zone of the twin-screw is set at 220, 260, 240, and 220° C., and the extruded mixture sample is granulated through a condensation water tank. The blend chips were dried at 60°C and pre-crystallized at 90°C for 4h. Solid state polymerization yields copolymer chips of desired viscosity in 5-30 hours. Solid state polymerization temperature: 210°C nitrogen protection (anti-oxidation, and take away small molecular by-products); nitrogen protection rapid sampling does not exceed 5 minutes.

[0033] sample

[0034] The synthesis and viscosity-increasing process of the resulting copolymers are shown in the attached image 3 shown.

Embodiment 2

[0035] The preparation of embodiment 2 PET-DDS (2mol%)

[0036] Put the PET slices in an ordinary oven at 90°C for 4 hours, then dry them in a vacuum oven at 120°C for 4 hours, mix them with DDS and set them aside. The temperature of each zone of the twin-screw is set at 220, 260, 244, and 230° C., and the extruded mixture sample is granulated through a condensation water tank. The blend slices were dried at 6°C and pre-crystallized at 90°C for 4h. Solid state polymerization yielded copolymer chips with the desired intrinsic viscosity of 0.64±0.02 in 40 hours. Solid phase polymerization temperature: 240°C nitrogen protection (anti-oxidation, and take away small molecular by-products).

Embodiment 3

[0037] Example 3 PET-DDS (2%) was used as a masterbatch to obtain PET-DDS (0.1mol%, 0.5mol% and 2mol%)

[0038] project

Pure PET

PET / 0.1%DD

S

PET / 0.5%DDS

PET / 2%DDS

Screw temperature / ℃

I

II

III

IV

metering pump and

Bending temperature / ℃

Cabinet temperature / ℃

Spinneret specification / mm*f

Spinning speed / m min -1

Heat roller temperature / ℃

Hot plate temperature / ℃

Denier (dtex) (10 4 )

Elongation at break (%)

Breaking strength (CN / dtex)

290

305

298

295

295

310

2.0

0.3*36

800

3.8

80

160

1.0515

7.201

2.44

290

305

298

295

295

310

2.0

0.3*36

800

3.8

80

135

1.0177

32.435

3.67

290

305

280

280

295

310

2.0

0.3*36

800

3.8

80

160

1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com