Nano TiO2 carrying metal ion antibacterial agent and its preparing method

A technology of nano-titanium dioxide and metal ions, applied in botany equipment and methods, biocides, disinfectants, etc., can solve the problem that light and heat conditions are greatly affected, the catalytic antibacterial effect is unsatisfactory, and the antibacterial effect cannot be effectively improved. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

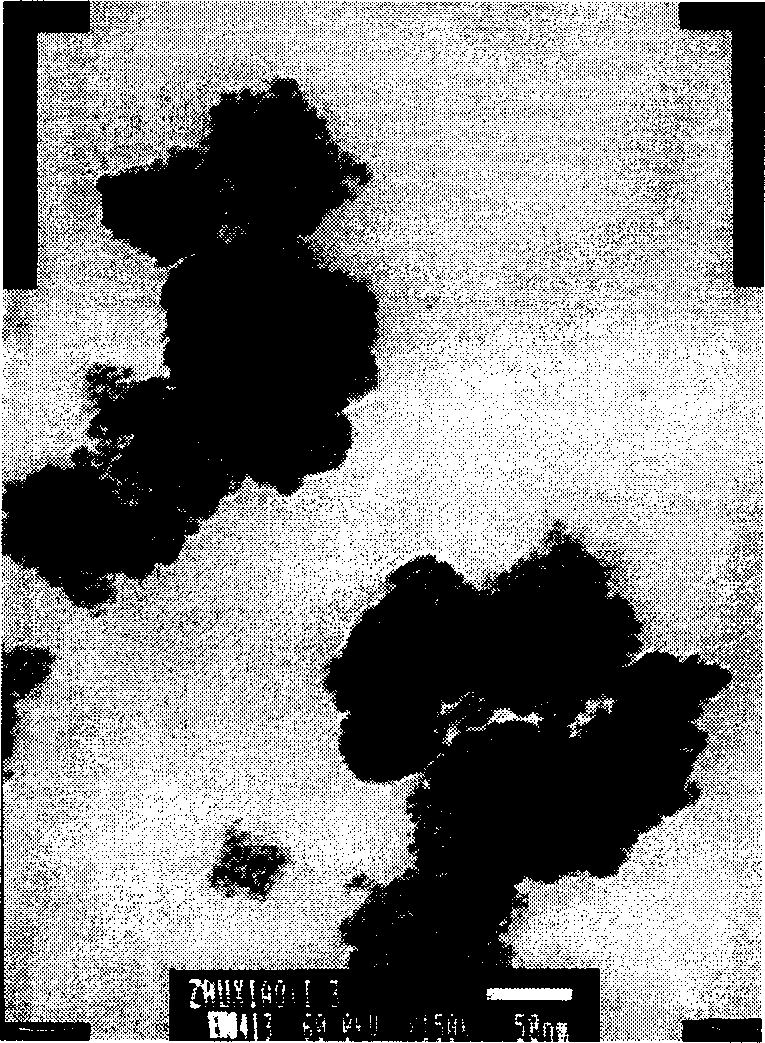

[0026] Embodiment 1: first with 3g nano-titanium dioxide raw material (properties refer to figure 1 ) soaked in 50ml deionized water, soaked for 5min, soaked at 40°C, dispersed by ultrasonic wave, dispersed for 20min, then added 0.425g of silver nitrate for mixing and dissolving, and stirred it. During this process, the pH value of the mixture Use 0.1mol / L sulfuric acid (nitric acid) to adjust to 3, the temperature of mixing and stirring is 30°C, the time of mixing and stirring is 5h, the solid is obtained by centrifugal filtration, dried at 80°C for 3 hours, and the dried solid The product was roasted at 400° C. for 5 hours, and then ground with a ball mill to obtain a finished antibacterial agent, that is, titanium dioxide-loaded silver ion (silver ion attached to the carrier) antibacterial agent. Its properties and characteristics can be found in image 3 . The titanium dioxide-loaded silver ion antibacterial agent is used for finishing cotton fabrics, and the antibacteria...

Embodiment 2

[0028] Embodiment 2: first immerse 3g nano-titanium dioxide in 50ml deionized water, soak 20min, soak temperature 30 ℃, adopt ultrasonic wave to disperse, disperse time 30min, then add 0.24g silver nitrate and 0.06g zinc sulfate (between the two molar ratio is 3: 1) the mixture is mixed and dissolved, and it is stirred. During this process, the pH value of the mixed solution is adjusted to 5 with 0.1mol / L sulfuric acid (nitric acid), and the temperature of mixing and stirring is 50°C. The time is 7 hours, the solid is obtained by centrifugal filtration, dried at 100°C for 2 hours, the dried solid is roasted at 450°C for 4 hours, and then ground with a ball mill to obtain the finished antibacterial agent, namely titanium dioxide loaded with silver and zinc ion antibacterial agent.

[0029] In addition to the above-mentioned combination of silver nitrate and zinc sulfate, metal salts also have combinations of silver nitrate and copper nitrate, copper nitrate and zinc sulfate, an...

Embodiment 3

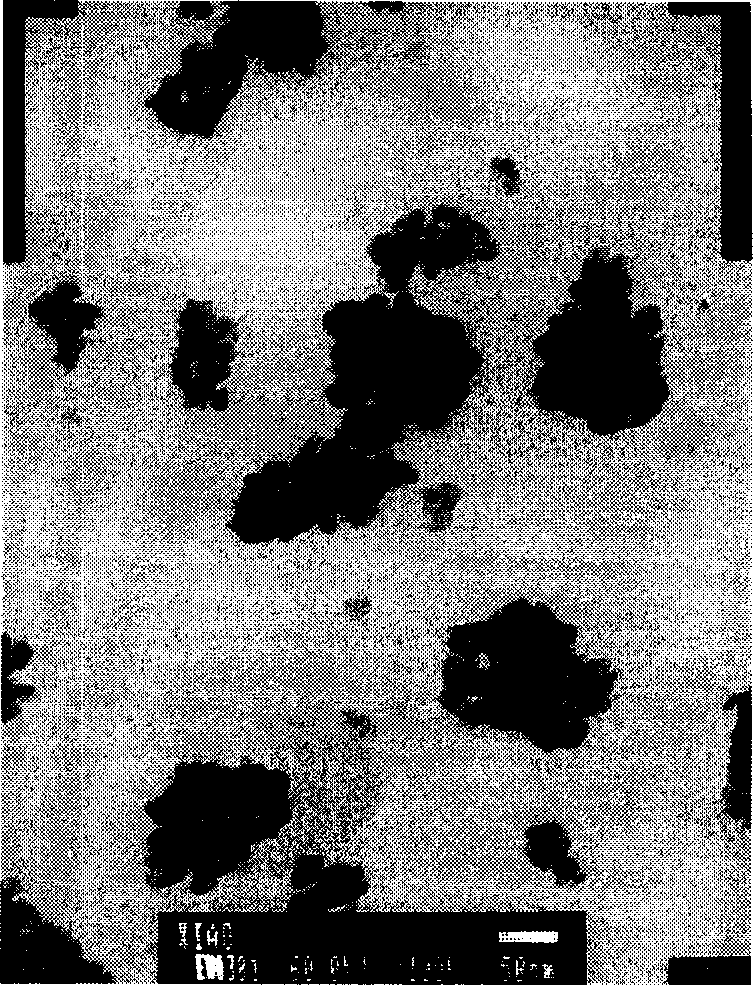

[0031] Example 3: First soak 3g of nano-titanium dioxide in 50ml of deionized water, soak for 40min, soak at a temperature of 15°C, and disperse with ultrasonic waves for 50min, then add 0.182g of silver nitrate, 0.045g, zinc sulfate and 0.045g of copper nitrate (The molar ratio between the three is 3:1:3) the mixture is mixed and dissolved, and it is stirred. During this process, the pH value of the suspension is adjusted to 7 with 0.1mol / L sulfuric acid (nitric acid), and mixed and stirred The temperature is 70°C, the mixing and stirring time is 10h, the solid is obtained by centrifugal filtration, dried at 125°C for 1.5 hours, the dried solid is roasted at 500°C for 3 hours, and then ground with a ball mill to obtain the finished antibacterial product The antibacterial agent is titanium dioxide loaded with silver, zinc and copper ions, and its properties and characteristics can be found in Figure 4 .

[0032] After testing, it is known that the combination of three metal ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com