Multifunctional photocatalysis composite ceramic separation membrane as well as preparation method and use thereof

A technology of composite ceramics and porous ceramic membranes, applied in catalyst activation/preparation, chemical instruments and methods, semi-permeable membrane separation, etc., can solve problems such as limited photocatalytic activity, low membrane effluent flux, and loss of porosity. High adsorption separation performance and photocatalytic ability, simple preparation and application process, and the effect of reducing porosity loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] When the permeation flux of the composite membrane is required to be small or the pore size is small, the multifunctional photocatalytic composite ceramic separation membrane prepared under the following conditions can be applied.

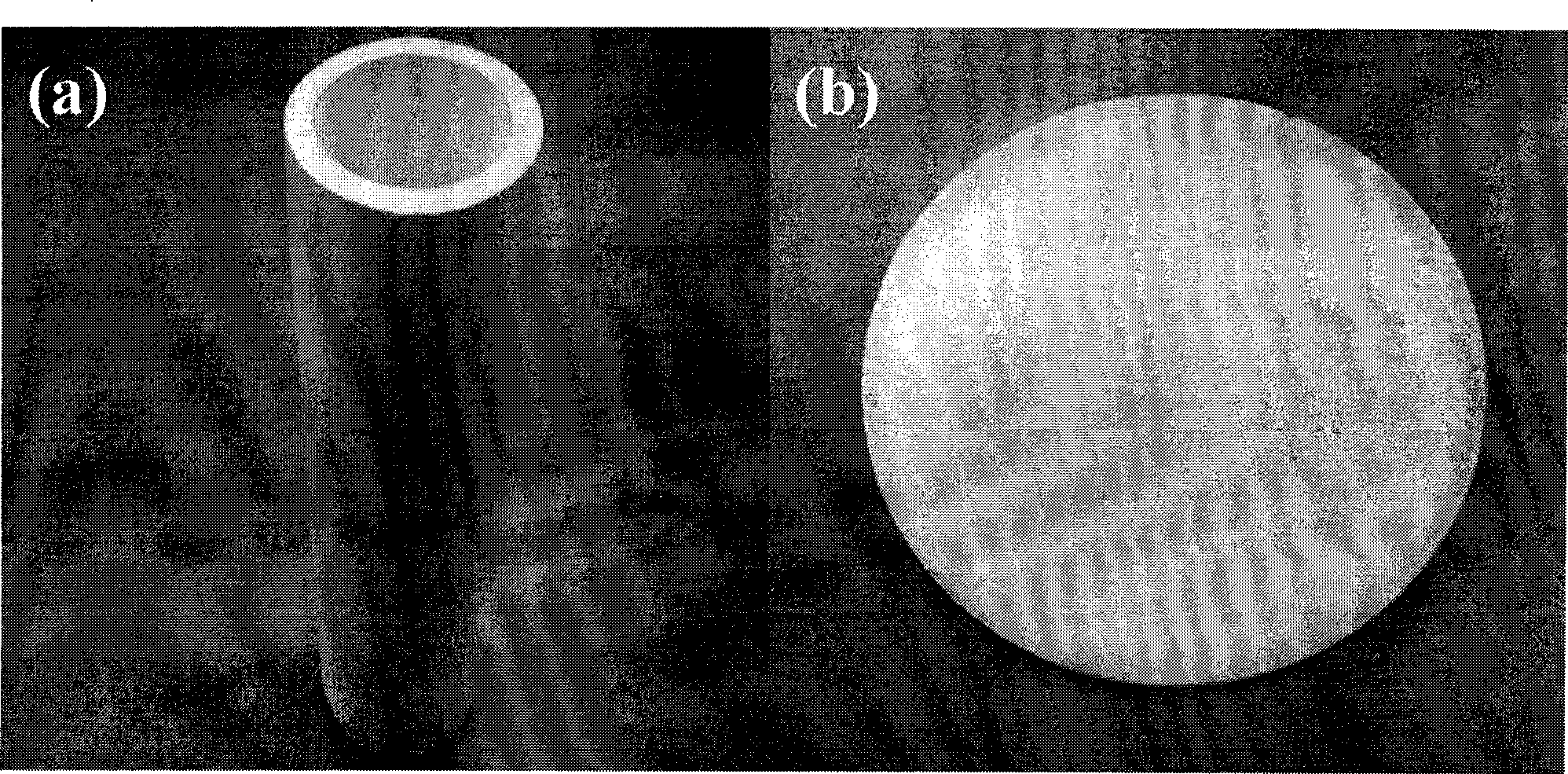

[0054] ZrO with a pore size of 200nm and a porosity of 25% 2 The ceramic membrane is used as a carrier to prepare a multifunctional photocatalytic composite ceramic separation membrane with a pore size of 100-150nm. The steps are:

[0055] The first step, the pretreatment of the carrier

[0056] ZrO will be used as carrier 2 The ceramic membrane was cleaned with deionized water and dried at 40°C, then cooled down to room temperature naturally for later use;

[0057] The second step, the preparation of hydroxyapatite sol

[0058] Diammonium hydrogen phosphate and calcium nitrate solutions were prepared at a molar ratio of 3:5, and the respective pH values were adjusted to 7 with ammonia water. Slowly drop the diammonium hydrogen phospha...

Embodiment 2

[0067] For the treatment of source water containing NOMs, bacteria, algae, etc., such as the treatment of five types of surface water as drinking water sources, the multifunctional photocatalytic composite ceramic separation membrane prepared under the following conditions can be used.

[0068] Al with a pore size of 1000nm and a porosity of 50% 2 0 3 The inorganic membrane is used as a carrier to prepare a multifunctional photocatalytic composite ceramic separation membrane with a pore size of 850-950nm. The steps are:

[0069] The first step, the pretreatment of the carrier

[0070] Al will be used as carrier 2 o 3 After the inorganic membrane was washed with deionized water and dried at 70°C, the temperature was naturally cooled to room temperature for later use;

[0071] The second step, the preparation of hydroxyapatite sol

[0072]Diammonium hydrogen phosphate and calcium nitrate solutions were prepared at a ratio of 3:5, and the respective pH values were adjusted...

Embodiment 3

[0081] For the treatment of source water containing suspended solid particles and containing NOMs, bacteria, algae, etc., the multifunctional photocatalytic composite ceramic separation membrane can be prepared under the following conditions.

[0082] SiO with a pore size of 2000nm and a porosity of 60% 2 The inorganic membrane is used as a carrier to prepare a multifunctional photocatalytic composite ceramic separation membrane with a pore size of 1800-1900nm. The steps are:

[0083] The first step, the pretreatment of the carrier

[0084] SiO will be used as carrier 2 The inorganic membrane was washed with deionized water and dried at 100°C, then cooled down to room temperature naturally for later use;

[0085] The second step, the preparation of hydroxyapatite sol

[0086] Diammonium hydrogen phosphate and calcium nitrate solutions were prepared at a ratio of 3:5, and the respective pH values were adjusted to 11 with ammonia water. Slowly drop the diammonium hydrogen ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com