Cement dispersing agent and concrete composition comprising same

A technology of concrete composition and cement dispersant, which is applied in the direction of amide/imide polymer adhesives, adhesive types, etc., and can solve the problems of not being able to achieve creep performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066]

[0067] 103 g (1.00 mol) of diethylenetriamine and 97.3 g (0.67 mol) of adipic acid were placed in a reaction vessel provided with a stirrer, and the mixture was stirred and mixed in a nitrogen atmosphere by passing nitrogen gas. The temperature was raised to 150° C., the water produced by the reaction was removed while the polycondensation was performed, and the reaction was carried out for 20 hours until the acid value became 22. Then, 1.1 g of hydroquinone methyl ether and 27.5 g (0.32 mol) of methacrylic acid were added, and the mixture was reacted at the same temperature (150° C.) for 10 hours. Thus, a total of 42 g of reaction distilled water and 187 g of polyamide polyamine (melting point 122° C., acid value 23) were obtained. The whole amount of this polyamide polyamine was dissolved in 272 g of water, and the temperature was raised to 50°C. Further, 220 g of ethylene oxide (corresponding to 3.0 mol with respect to the total amount of amino residues includin...

Embodiment 2~9

[0082] In the same manner as in Example 1, A-2 to A-6, which are polyamide polyamine alkylene oxide adducts, were obtained from the raw materials shown in Table 1. In addition, using Compound A, Compound B, Compound C, and Compound D shown in Table 2, copolymerization was carried out in the same preparation method as in Example 1 to obtain water-soluble amphoteric copolymers (Examples 2 to 9) (however, it was necessary to adjust Moisture makes the solid content of the obtained copolymer 40%).

[0083] [Table 1]

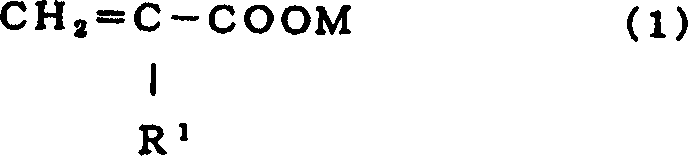

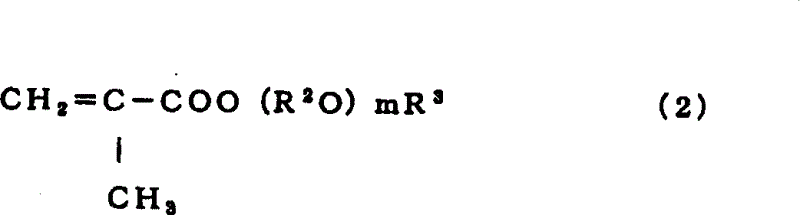

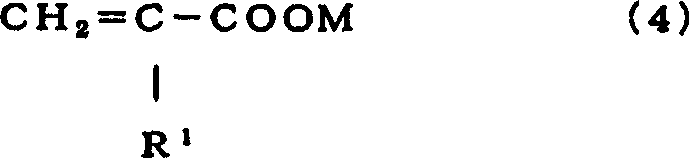

[0084] Compound A

A-1

A-2

A-3

A-4

A-5

A-6

(a)DETA*2

TETA*3

(b) Adipic acid

Dimethyl adipate

Acid value of intermediate condensate*4

(c) Acrylic

Acid value of final condensate*5

(d) Ethylene oxide

1.00

-

0.67

-

22

-

0.32

-

23

3.0

-

1.00

-

0.83

-

19

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com