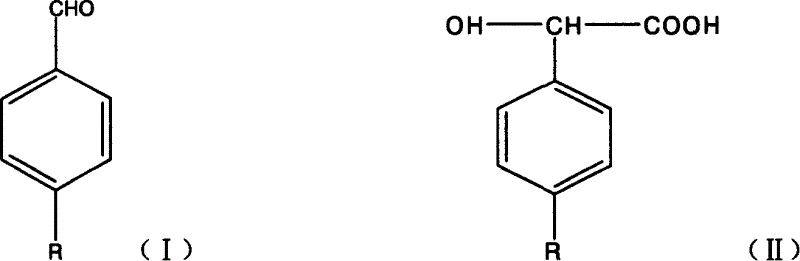

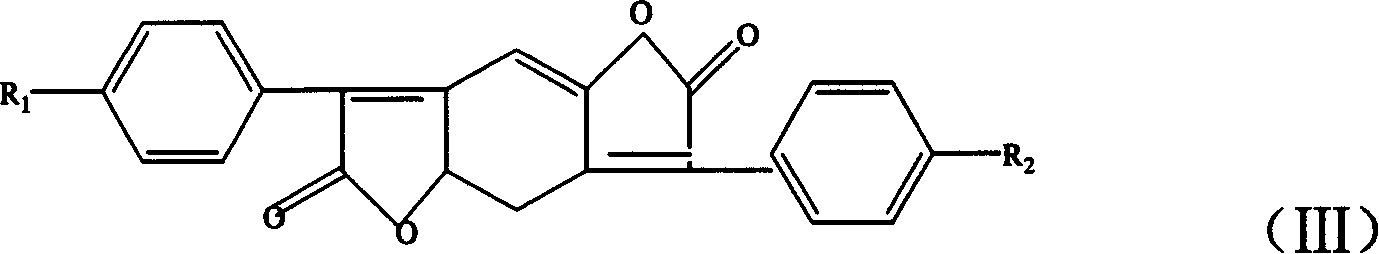

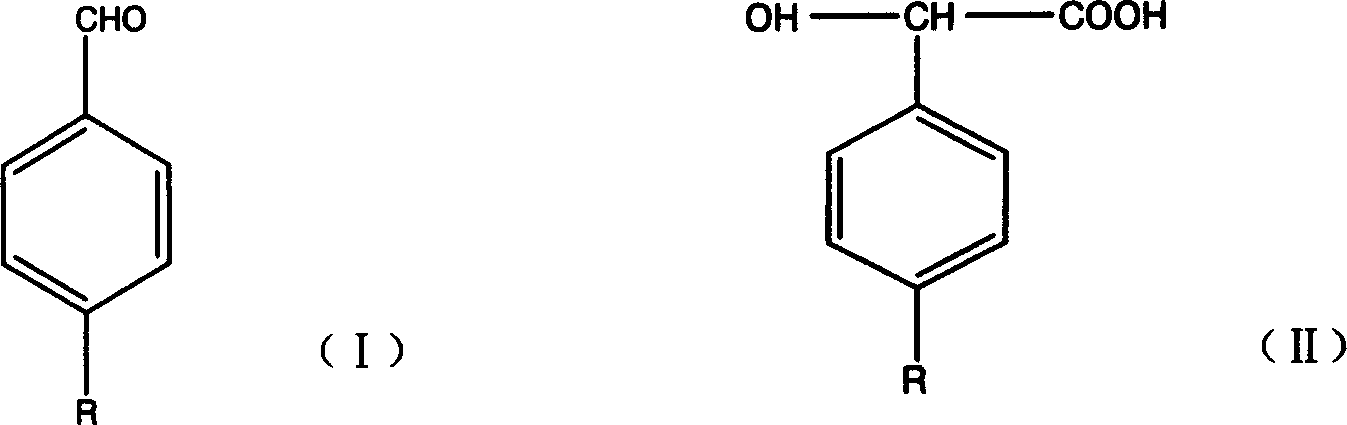

Preparation technology of benzodifaradone kind disperse red dye and its product

A technology of benzodifuranone and disperse red, which is applied in the direction of organic dyes, azo dyes, chemical instruments and methods, etc., can solve the problems of poor wet fastness and perspiration fastness, insufficient performance of microfibers, molar The extinction coefficient is not high, so as to achieve the effects of less environmental pollution, bright color and shortened process time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1. Synthesis of mandelic acid: add 23 parts of benzaldehyde in a 250ml three-necked flask, 20ml of chloroform, 3 parts of composite catalyst triethyl-benzyl-ammonium bromide, octaalkyl-trimethyl-ammonium bromide, Control the reaction temperature at 30°C, add 50 parts of 60% caustic soda solution, stir for 6 hours, add 200 parts of water, remove the organic layer, adjust the pH value to 1 with 30% hydrochloric acid, cool to 5°C, filter and dry Get mandelic acid.

[0027]2. Semi-condensation reaction: Add 20 parts of hydroquinone and 24 parts of mandelic acid into a 250ml three-necked flask, stir for 3 hours, add 60 parts of 40% sulfuric acid, control the temperature at 60°C, keep it warm for 12 hours, and cool down to At 15°C, pour into ice water, filter, wash, and dry to obtain the semi-condensed product.

[0028] 3. Full condensation reaction: Add 10 parts of semi-condensed products and 90 parts of acetic acid containing sulfuric acid into a 250ml three-necked flask, ...

Embodiment 2

[0032] 1. Synthesis of mandelic acid: Add 23 parts of propoxybenzaldehyde, 15ml of acetone, 5ml of chloroform in a 250ml three-necked flask, composite catalyst triethyl-benzyl-ammonium bromide, nonalkyl-trimethyl- 3 parts of ammonium bromide, the reaction temperature is controlled at 45°C, add 50 parts of 60% caustic soda solution, stir for 5 hours, add 200 parts of water, remove the organic layer, adjust the pH value to 2 with 30% hydrochloric acid, cool to 15°C, After filtering and drying, mandelic acid is obtained.

[0033] 2. Semi-condensation reaction: Add 20 parts of catechol and 24 parts of p-propoxymandelic acid into a 250ml three-neck flask, stir for 4 hours, add 60 parts of 60% sulfuric acid, control the temperature at 90°C, and keep it warm for 9 hours , cooled to 20°C, poured into ice water, filtered, washed and dried to obtain the semi-condensed product.

[0034] 3. Full condensation reaction: Add 10 parts of semi-condensation products and 90 parts of acetic acid...

Embodiment 3

[0038] 1. Synthesis of mandelic acid: Add 23 parts of benzaldehyde, 10ml of chloroform, 10ml of DMF, composite catalyst triethyl-benzyl-ammonium bromide, dedecyl-trimethyl-ammonium bromide in a 250ml three-necked flask Parts, the reaction temperature is controlled at 60°C, add 50 parts of 60% caustic soda solution, stir for 4 hours, add 200 parts of water, remove the organic layer, adjust the pH value to 3 with 30% hydrochloric acid, cool to 20°C, filter and dry Then get mandelic acid.

[0039] 2. Semi-condensation reaction: Add 20 parts of hydroquinone and 24 parts of mandelic acid into a 250ml three-necked flask, stir for 3 hours, add 60 parts of 75% sulfuric acid, control the temperature at 105°C, keep it warm for 6 hours, and cool down to At 25°C, pour into ice water, filter, wash, and dry to obtain the semi-condensed product.

[0040] 3. Full condensation reaction: Add 10 parts of semi-condensation products and 90 parts of acetic acid containing sulfuric acid in a 250ml ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle diameter | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com