Method for extracting potassium sulphate by magnesium sulfate sub-type potassium-containing salt lake brine water

A technology of magnesium sulfate subtype and potassium sulfate, which is applied in the direction of alkali metal sulfite/sulfate purification, etc., can solve the problems of saline lake edible salt pollution, inconvenience of potassium sulfate products, and inability to use potassium resources, so as to improve utilization rate, The effect of low production cost and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

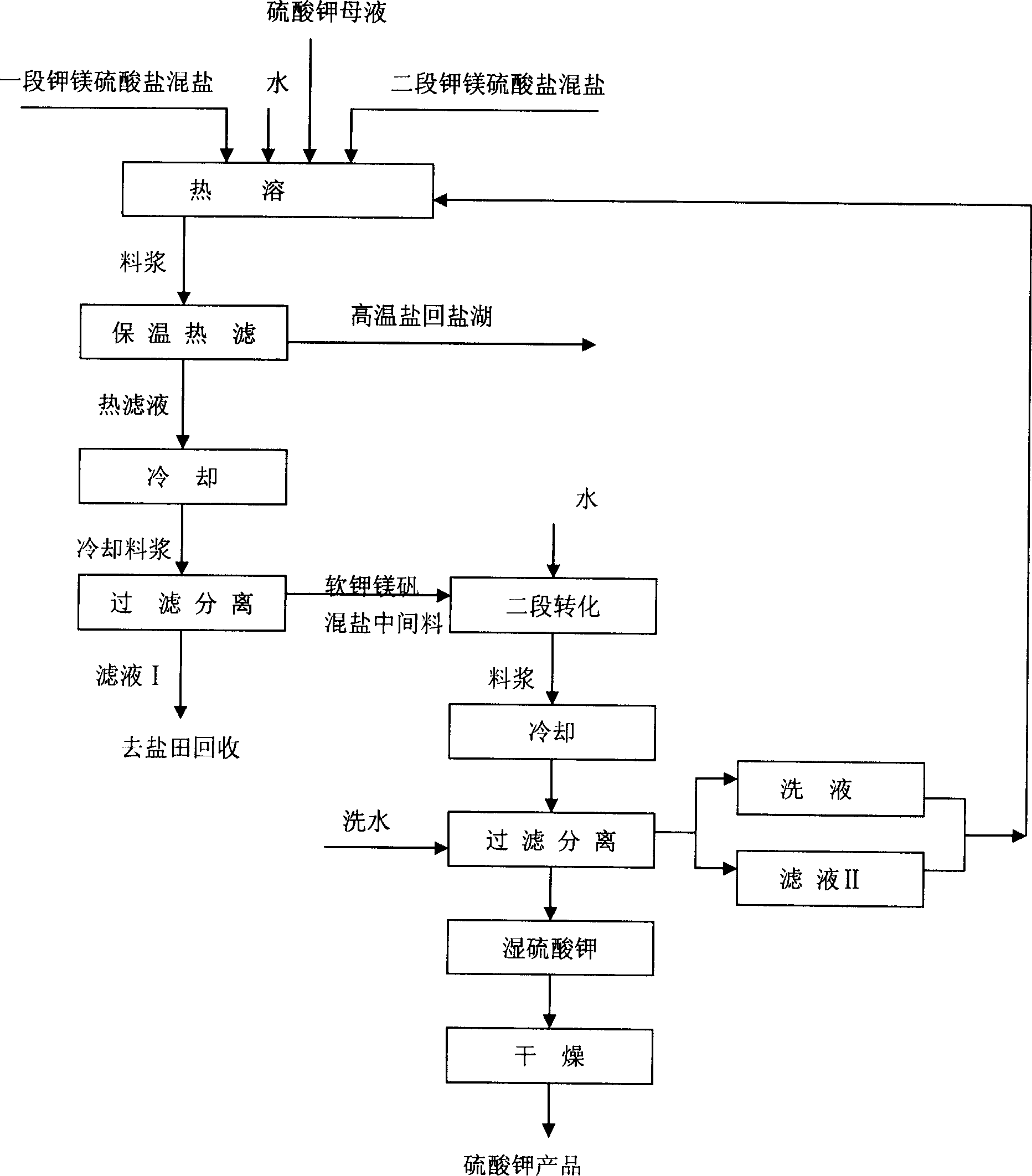

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1, utilize the method for extracting potassium sulfate from magnesium sulfate subtype potassium-containing salt lake brine, comprising the following processing steps:

[0024] ①The potassium-magnesium sulfate mixed salt mine and the second potassium magnesium sulfate mixed salt mine are respectively obtained by evaporating the magnesium sulfate subtype potassium-containing salt lake brine through the sun in the salt field, and the content of the main components of the potassium magnesium sulfate mixed salt mine in the first stage is controlled The range is: Na: 5-15%; Mg: 4-10%; K: 5-10%; C1: 15-30%; SO 4 : 10-25%; the content control range of the main components of the second-stage potassium-magnesium sulfate mixed salt mine is: Na: 5-10%; Mg: 4-10%; K: 8-12%; Cl: 20-38% ;SO 4 : 6-15%;

[0025] ②The above-mentioned one-stage and two-stage potassium-magnesium sulfate mixed salt ore, potassium sulfate mother liquor and water are batched according to the rati...

Embodiment 2

[0029] Embodiment 2, utilize the method for extracting potassium sulfate from magnesium sulfate subtype potassium-containing salt lake brine, comprising the following processing steps:

[0030] ①The potassium-magnesium sulfate mixed salt mine and the second potassium magnesium sulfate mixed salt mine are respectively obtained by evaporating the magnesium sulfate subtype potassium-containing salt lake brine through the sun in the salt field, and the content of the main components of the potassium magnesium sulfate mixed salt mine in the first stage is controlled The range is: Na: 5-15%; Mg: 4-10%; K: 5-10%; Cl: 15-30%; SO 4 : 10-25%; the content control range of the main components of the second-stage potassium-magnesium sulfate mixed salt mine is: Na: 5-10%; Mg: 4-10%; K: 8-12%; Cl: 20-38% ;SO 4 : 6-15%;

[0031] ②The above-mentioned first-stage and second-stage potassium-magnesium sulfate mixed salt ore, potassium sulfate mother liquor and water are batched according to the...

Embodiment 3

[0035] Embodiment 3, utilize the method for extracting potassium sulfate from magnesium sulfate subtype potassium-containing salt lake brine, comprising the following processing steps:

[0036]①The potassium-magnesium sulfate mixed salt mine and the second potassium magnesium sulfate mixed salt mine are respectively obtained by evaporating the magnesium sulfate subtype potassium-containing salt lake brine through the sun in the salt field, and the content of the main components of the potassium magnesium sulfate mixed salt mine in the first stage is controlled The range is: Na: 5-15%; Mg: 4-10%; K: 5-10%; C1: 15-30%; SO 4 : 10-25%; the content control range of the main components of the second-stage potassium-magnesium sulfate mixed salt mine is: Na: 5-10%; Mg: 4-10%; K: 8-12%; Cl: 20-38% ;SO 4 : 6-15%;

[0037] ②The above-mentioned first-stage and second-stage potassium-magnesium sulfate mixed salt ore, potassium sulfate mother liquor and water are batched according to the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com