Hydrothermal method for preparation of shape-controllable low-hydrate zinc borate powder

A technology of zinc water borate and hydrothermal method, applied in the directions of borates, chemical instruments and methods, zinc compounds, etc., can solve the problems of inability to meet the requirements of scientific and technological development, high price of surfactants, harsh conditions, etc., to avoid Powder agglomeration and impurity introduction, improved mechanical properties and appearance, mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

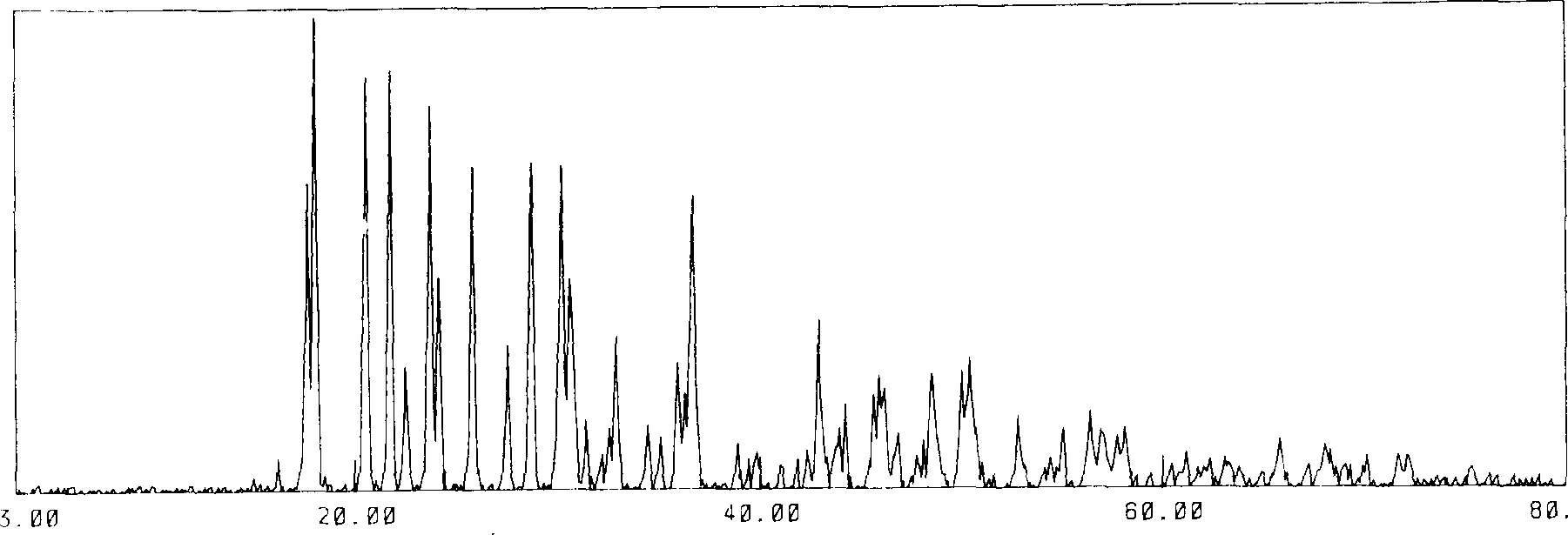

[0028] Embodiment 1, the preparation of granular low-water zinc borate of the present invention:

[0029] ① Raw material preparation: first weigh boric acid, zinc oxide and deionized water according to the mass ratio of 1:0.18:5; then add zinc oxide to deionized water, and add boric acid in batches under the condition of sufficient stirring It is mixed evenly; ②Charging: transfer the mixed precursor into an autoclave lined with polytetrafluoroethylene, adjust the filling degree to 65%, and then tighten the autoclave; ③Hydrothermal reaction: put the reaction autoclave in In an oven at 110°C, the rate of rise is 3-6°C / min. After reacting for 24 hours, cool down to room temperature naturally, and open the kettle to take samples after aging for 5 hours; Wash with distilled water and absolute ethanol for 3 to 6 times respectively, and then dry at 105°C for 10 hours to obtain a white powder which is a low-water zinc borate powder product. The main phase of this product is 2ZnO·3B ...

Embodiment 2

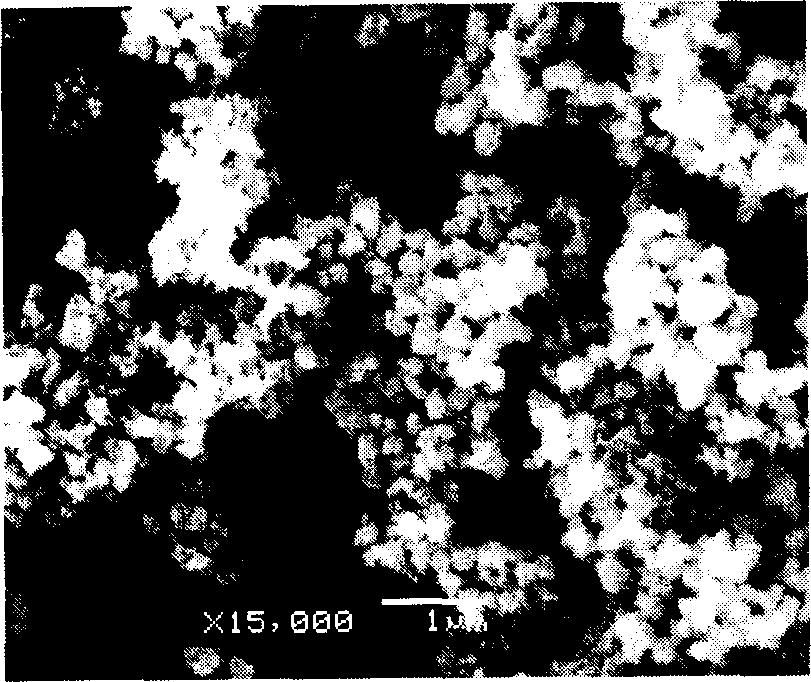

[0030] Embodiment 2, the preparation of granular low-water zinc borate of the present invention:

[0031] ① Raw material preparation: first weigh boric acid, zinc oxide and deionized water according to the mass ratio of 1:0.25:6; It is mixed evenly; ②Charging: transfer the mixed precursor into the autoclave lined with polytetrafluoroethylene, adjust the filling degree to 75%, and then tighten the autoclave; ③Hydrothermal reaction: put the reaction autoclave in In an oven at 140°C, the rate of increase is 3-6°C / min. After reacting for 10 hours, cool down to room temperature naturally, and take samples after aging for 8 hours; Wash with distilled water and absolute ethanol for 3 to 6 times respectively, and then dry at 100°C for 12 hours to obtain a white powder which is a low-water zinc borate powder product. The main phase of this product is 2ZnO·3B 2 o 3 ·3H 2 O powder, the product is in the form of granules, good dispersibility, uniform particle size, and the particle si...

Embodiment 3

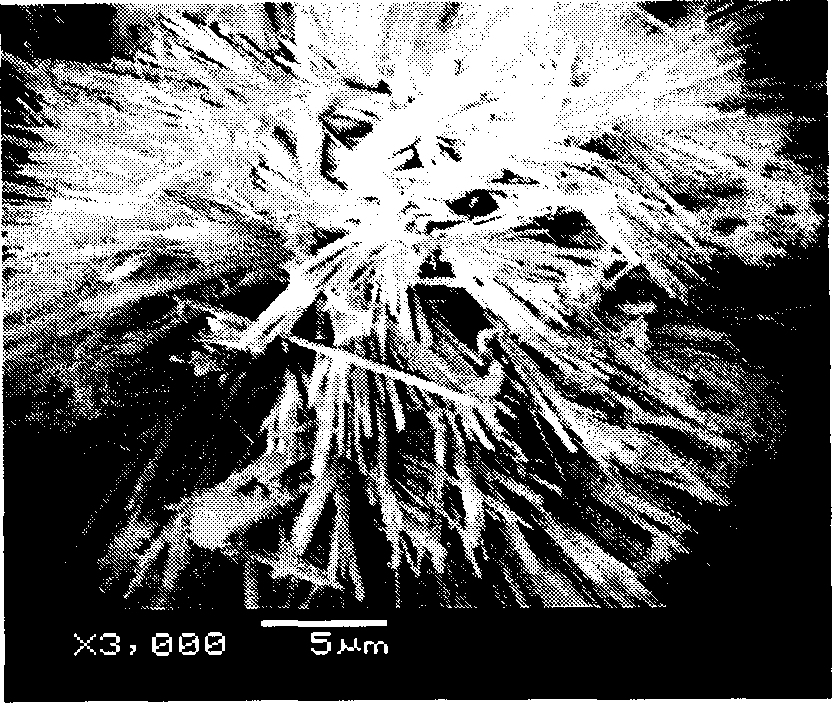

[0032] Embodiment 3: the preparation of granular low-water zinc borate of the present invention:

[0033] ① Raw material preparation: first weigh boric acid, zinc oxide and deionized water according to the mass ratio of 1:0.43:8; then add zinc oxide to deionized water, and add boric acid in batches under the condition of sufficient stirring It is mixed evenly; ②Charging: transfer the mixed precursor into an autoclave lined with polytetrafluoroethylene, adjust the filling degree to 85%, and then tighten the autoclave; ③Hydrothermal reaction: put the reaction autoclave in In an oven at 160°C, the rate of increase is 3-6°C / min. After reacting for 6 hours, cool down to room temperature naturally, and open the kettle to take samples after aging for 10 hours; Wash with distilled water and absolute ethanol for 3 to 6 times respectively, and then dry at 110°C for 8 hours to obtain a white powder which is a low-water zinc borate powder product. The main phase of this product is 2ZnO·3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com