Method for directional growth of zinc oxide nano-belt

A zinc oxide nanometer, directional growth technology, applied in the direction of zinc oxide/zinc hydroxide, etc., can solve the problems of controllable synthesis of refractory zinc oxide nanoribbons, self-assembly of directional growth zinc oxide nanomaterials, high reaction temperature, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

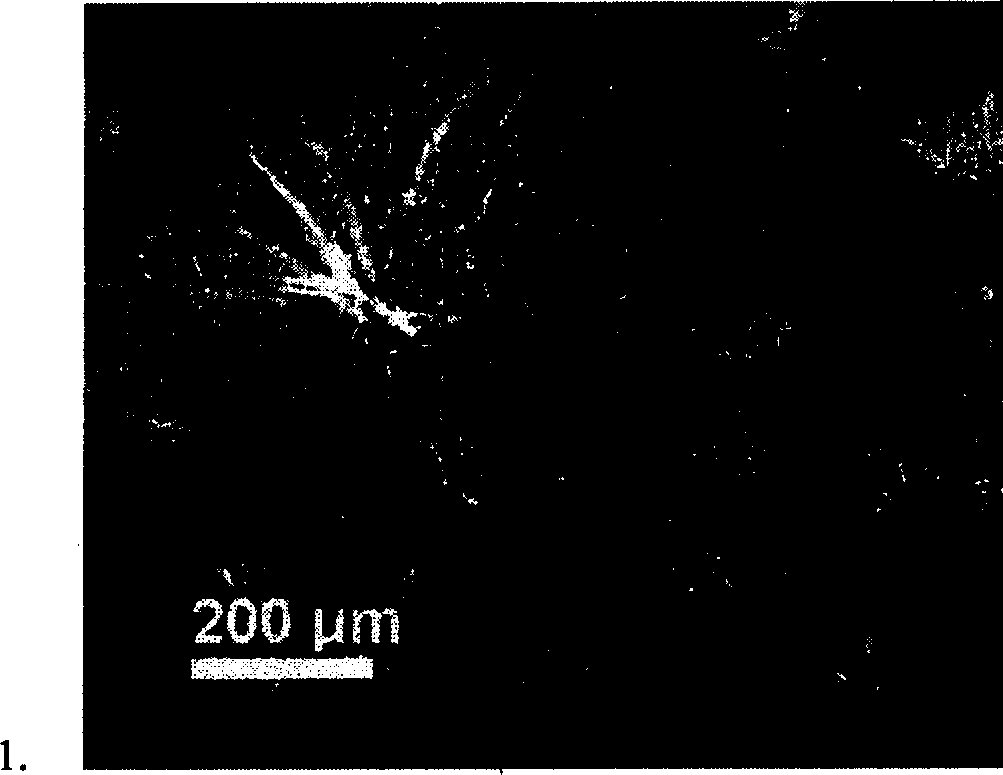

[0026]The diameter of the reactor is 20 mm, and the length of the electric heating furnace is 200 m. Commercially available zinc oxide powder (99.9%) and graphite powder (99%) are mixed in equal mass, ground uniformly, and then placed in a reactor. Fully mix and disperse alcohol and copper oxalate at a mass ratio of 10:1 to form a mixed solution, and coat it on the silicon substrate, then place the treated silicon substrate in the downstream low-temperature area of the reactor gas flow direction to collect the product . Argon (99.9%) was used as carrier gas with a flow rate of 25 sccm. The reactor was heated to 950°C at a speed of 30°C / min, the reaction time was 40min, and the product was deposited in the area of about 800°C. A white deposit was obtained on the silicon substrate, and its morphology was as follows figure 1 shown.

Embodiment 2

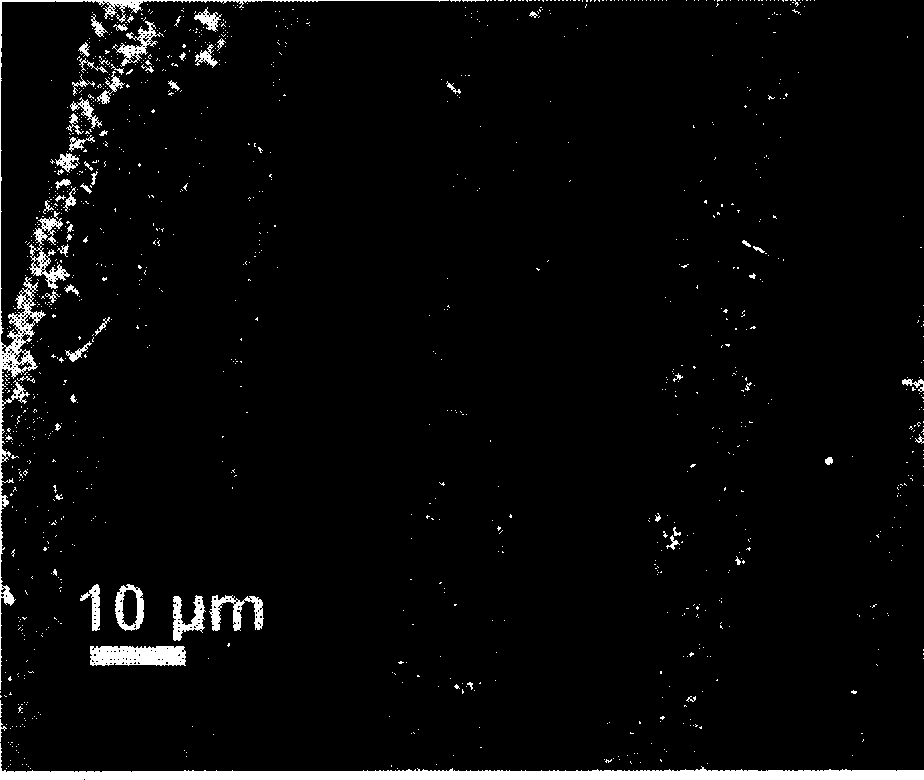

[0028] The diameter of the reactor is 20 mm, and the length of the electric heating furnace is 200 mm. Commercially available zinc oxide powder (99.9%) and graphite powder (99%) are mixed in equal mass, ground uniformly, and then placed in a reactor. Fully mix and disperse alcohol and copper oxalate at a mass ratio of 10:1 to form a mixed solution, then impregnate the carbon cloth in the suspension, take it out and dry it, and place it in the downstream low-temperature area of the reactor gas flow direction to collect the product. Argon (99.9%) was used as the carrier gas with a flow rate of 25 sccm. The reactor was heated up to 900°C at a speed of 30°C / min, and the reaction time was 60 minutes, and the product was deposited in the area of 500°C. A white or light gray deposit is obtained on the substrate, and the form of the product is as follows figure 2 shown.

Embodiment 3

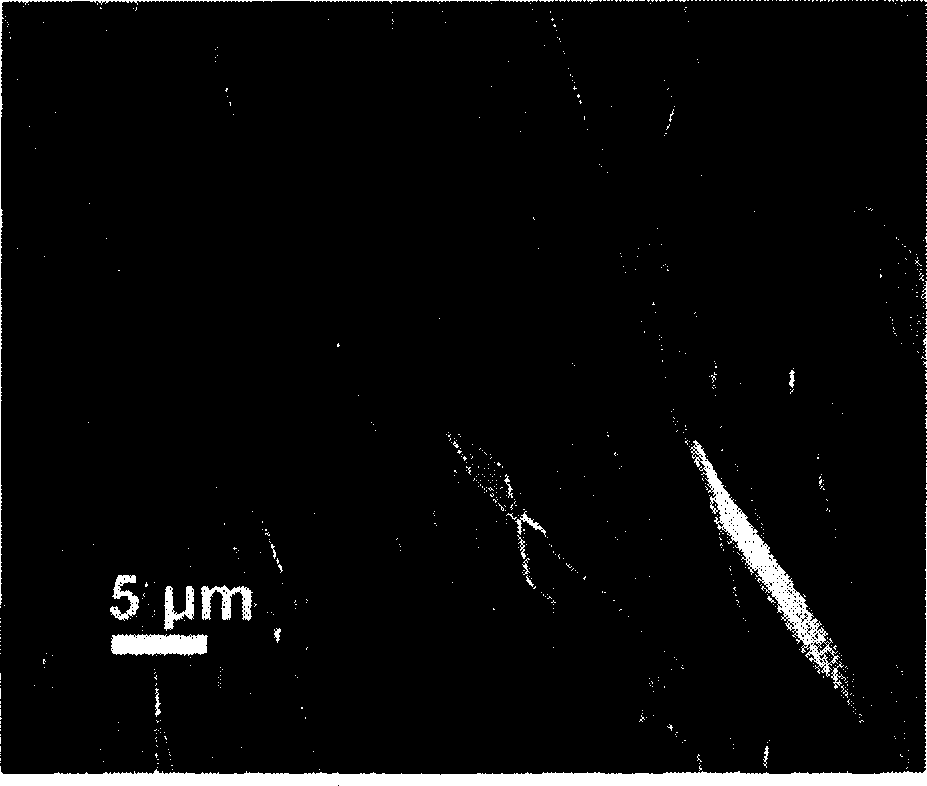

[0030] The diameter of the reactor is 20 mm, and the length of the electric heating furnace is 200 mm. Commercially available zinc oxide powder (99.9%) and graphite powder (99%) are mixed in mass, ground uniformly, and then placed in a reactor. The active copper oxide particles are dispersed on the porous nickel substrate as a catalyst, and placed in the downstream low temperature area of the reactor gas flow direction to collect the product. Argon (99.9%) was used as the carrier gas with a flow rate of 25 sccm. The reactor was heated to 950°C at a speed of 30°C / min, and the reaction time was 30 minutes, and the product was deposited in the area of 700°C. A white deposit was obtained on the substrate, and the form of the product was as image 3 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com