Process for preparing limellar stripping nano imvite

A nano-montmorillonite and montmorillonite technology, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve the problems of lack of nano-features and limited application scope, and achieve the effect of improving yield and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0028] The preparation method of exfoliated nano-montmorillonite of the present invention, it may further comprise the steps:

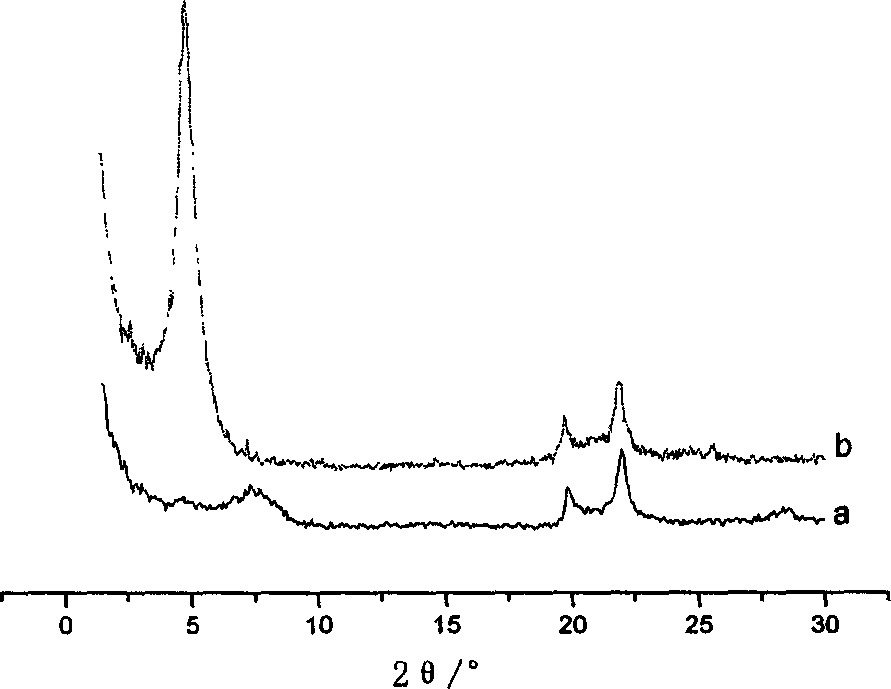

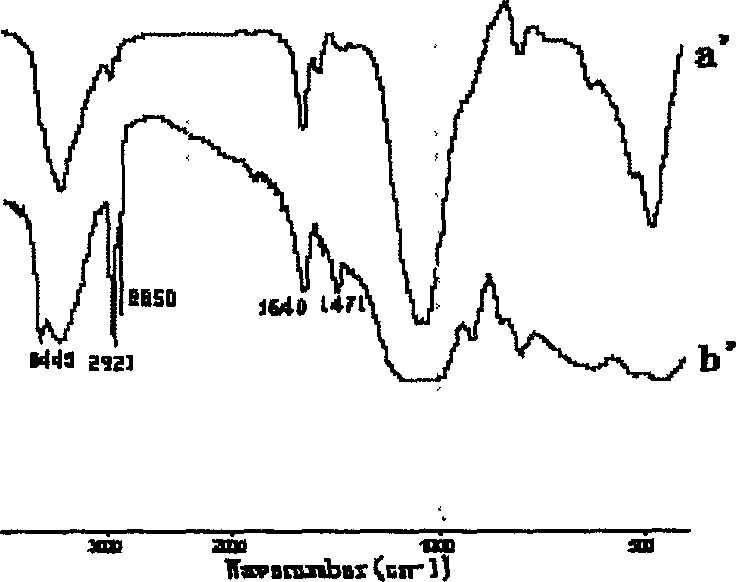

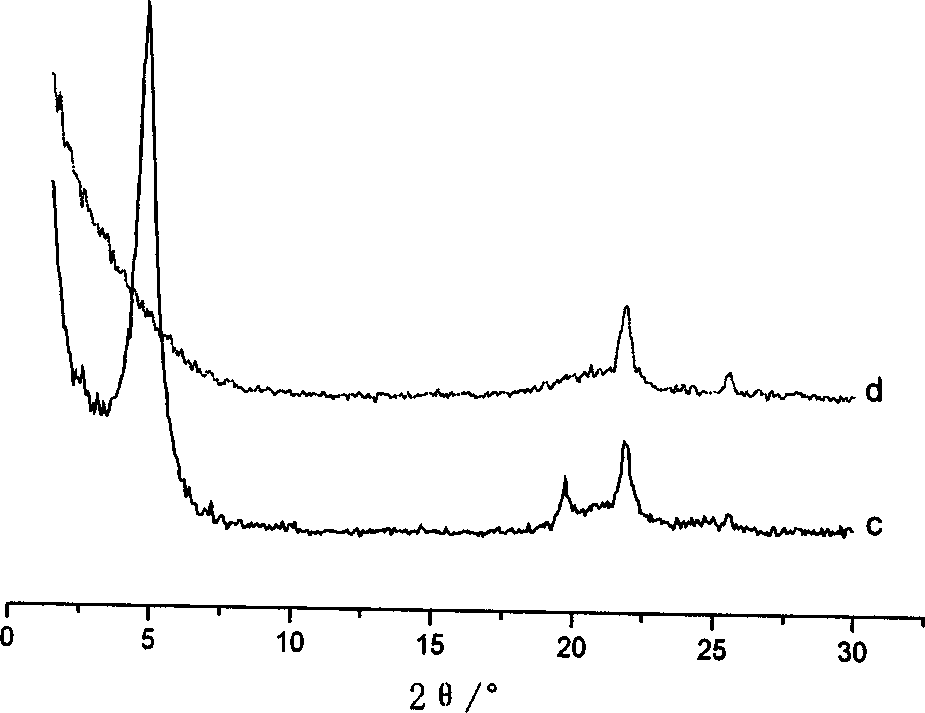

[0029] Organic intercalation modification of sodium-based montmorillonite by mechanochemical method: Take 20g of sodium-based montmorillonite with a cation exchange capacity of 80mmol / 100g, add it to 200ml of distilled water, and fully disperse it. : The ratio of 2 is taken in an appropriate amount, and the two are added together in the tank of the ball mill; according to the cation exchange capacity of the added montmorillonite, the organic intercalation modifier—hexadecyltrimethyl is weighed by 1.0 times of the exchange capacity Add 6.0g of ammonium bromide to 30ml of absolute ethanol, heat and stir at 80°C, pour it into the tank of the ball mill after it is completely dissolved; seal it, install the instrument, set the speed of the ball mill to 480 rpm, and reverse the time for 20 minutes. The reaction time is 60min, and organic intercalation modif...

example 2

[0033] The preparation method of exfoliated nano-montmorillonite of the present invention, it may further comprise the steps:

[0034] Use mechanochemical method to carry out organic intercalation modification to sodium-based montmorillonite: take 200ml of montmorillonite-containing sodium sulphate slurry, the cation exchange capacity of montmorillonite is 100mmol / 100g, and the ball mill corundum ball is 1.5∶2.5 : The ratio of 1.5 is taken in an appropriate amount, and the two are added together in the tank of the ball mill; according to the cation exchange capacity of the added montmorillonite, the organic intercalation modifier—octadecyltrimethyl is weighed by 1.5 times of the exchange capacity Add 12g of ammonium chloride to 50ml of absolute ethanol, heat and stir at 80°C, pour it into a ball mill jar after it is completely dissolved; seal it, install the instrument, set the speed of the ball mill to 560 rpm, reverse time to 20min, and the reaction time 120min, the organic ...

example 3

[0039] The preparation method of exfoliated nano-montmorillonite of the present invention, it may further comprise the steps:

[0040] Organic intercalation modification of sodium-based montmorillonite by mechanochemical method: Take 50g of sodium-based montmorillonite with a cation exchange capacity of 120mmol / 100g, add it to 400ml of distilled water, stir and disperse, first press the corundum balls of the ball mill into large, medium and small The ratio of 3.5:5:1.5 takes an appropriate amount and puts it into the tank of the ball mill, and then adds the sodium-based montmorillonite after stirring and dispersion into the tank of the ball mill; Weigh the organic intercalation modifier——dodecylbenzyldimethylammonium chloride 3.0g, dodecyldimethylbenzylammonium bromide 4.5g, dodecyltrimethylammonium chloride 6.0g, add the three organic intercalation modifiers into 100ml of methanol, heat and stir at 80°C, and pour it into the ball mill jar after it is completely dissolved; sea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com