Method for promoting ozone utilization rate and intensifying treatment effect of ozone contact-oxidation pool

A technology of ozone contact oxidation and enhanced treatment, applied in the direction of oxidized water/sewage treatment, etc., can solve the problems of low reaction rate of organic pollutants and ozone, difficult degradation of organic pollutants, unsatisfactory water treatment effect, etc., so as to improve the utilization of ozone. efficiency, easy structural improvement, and easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

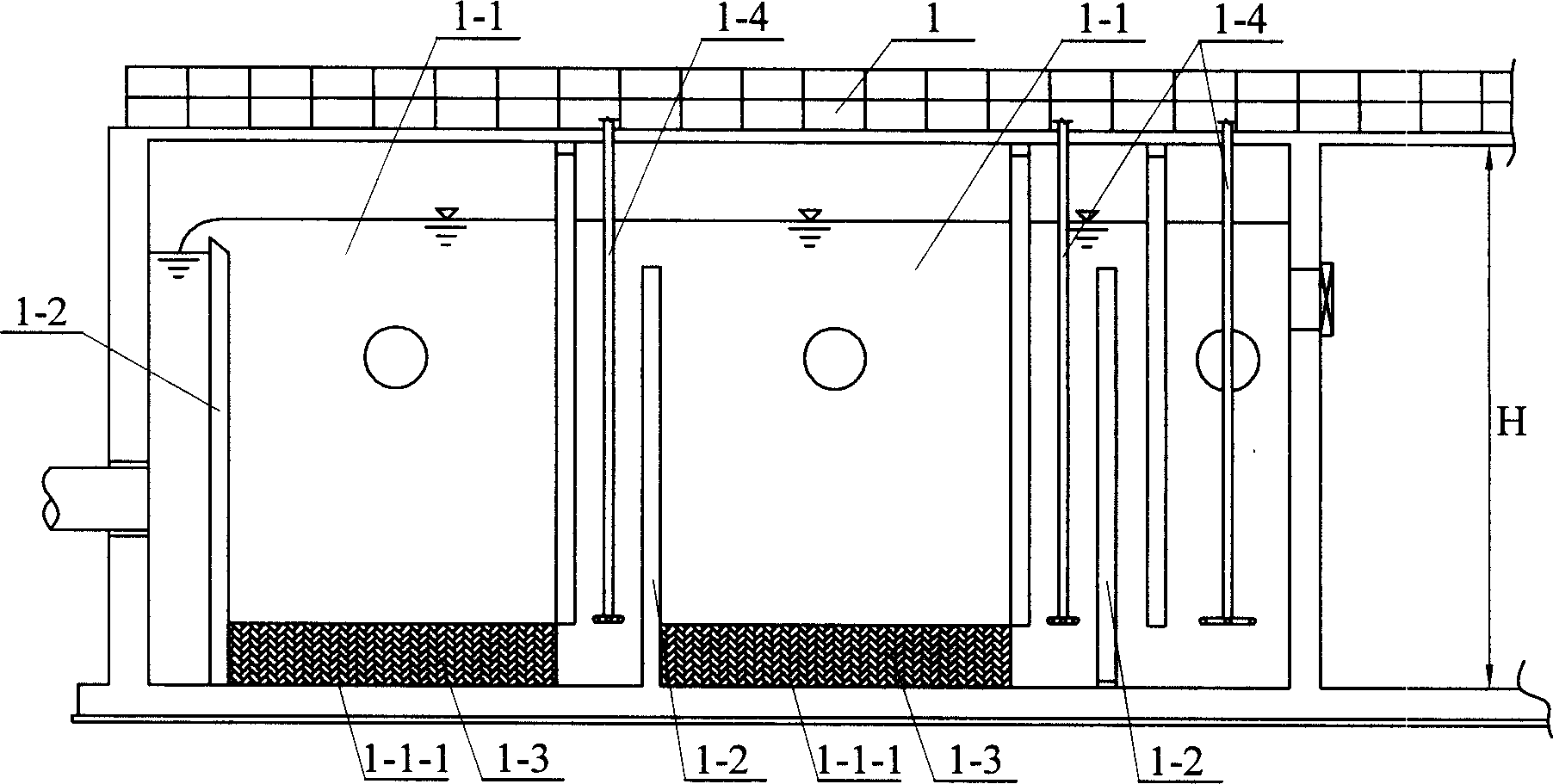

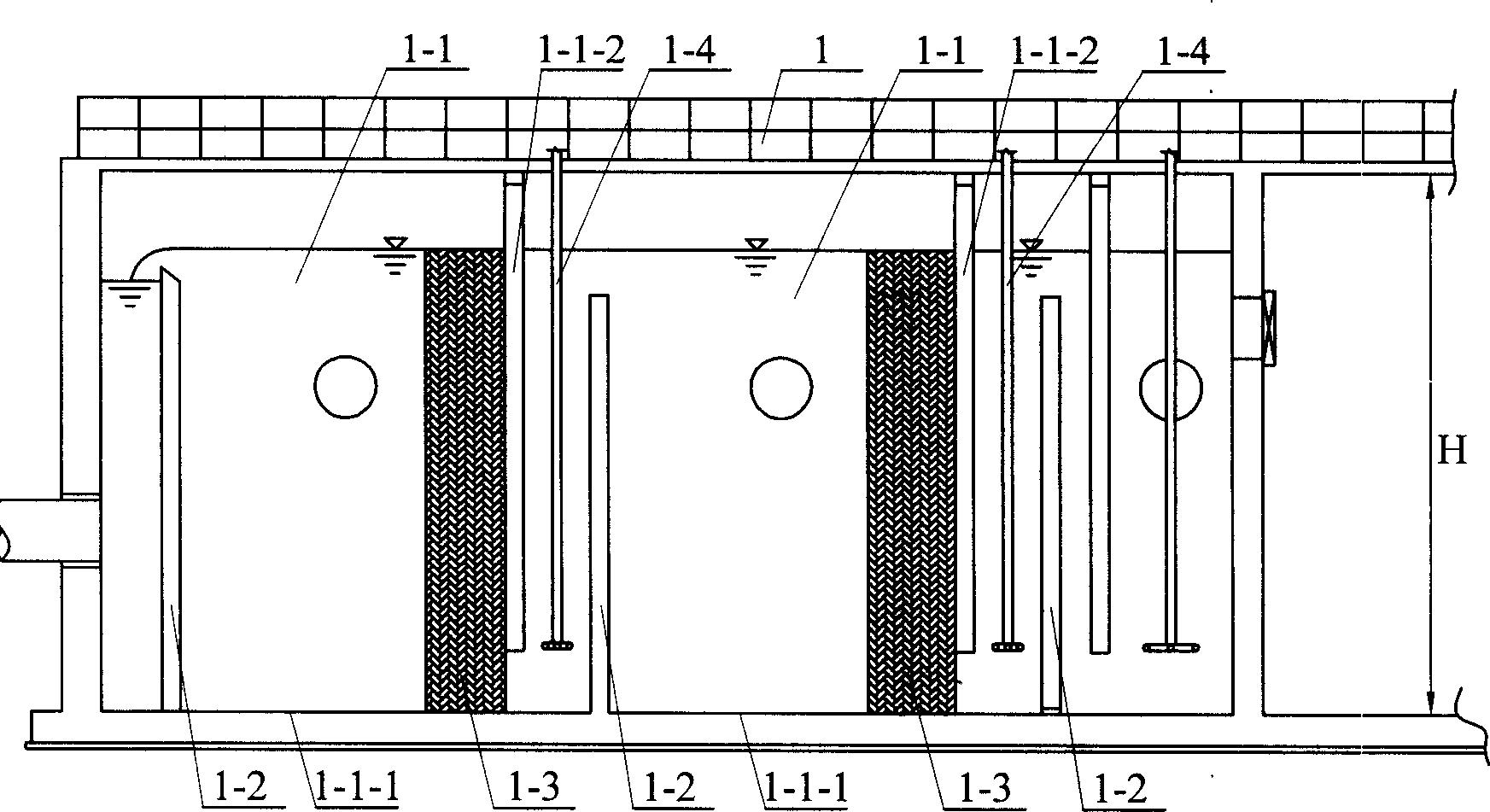

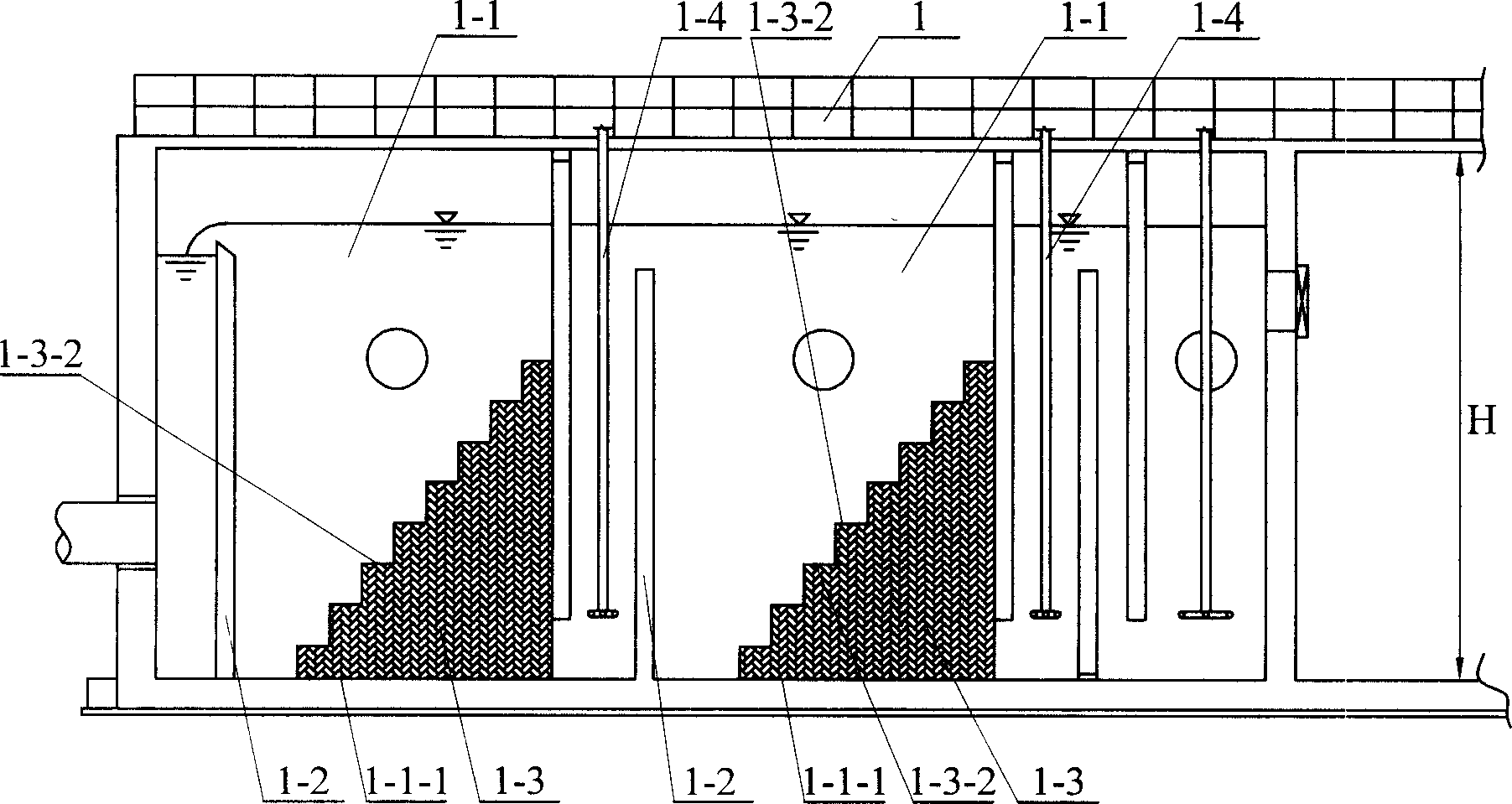

[0006] Specific implementation mode one: combine figure 1 , figure 2 , image 3 , Figure 4 Illustrate this embodiment, this embodiment is accomplished like this: first place porous medium filler 1-3 between two baffle plates 1-2 in each unit cell 1-1 in ozone contact oxidation tank 1, described The porous medium filler 1-3 is composed of porous medium and the surface of the porous medium is loaded with metal or metal oxide; then through the aeration pipe 1-4, it flows into the ozone contact oxidation tank 1 equipped with the porous medium filler 1-3 with bubble flow The oxidant is passed into the oxidant in a manner, and the diameter of the oxidant bubble is 20 μm to 5 mm; the oxidant is pure ozone or a mixed gas of ozone and oxygen or a mixed gas of ozone and air; the volume percentage of the ozone and oxygen is: ozone: 0.001-10%, oxygen: 90-99.999%; the volume percentage of ozone and air is: ozone: 0.001-10%, air: 90-99.999%, the concentration of ozone is 0.1-5.0mg / L, ...

specific Embodiment approach 2

[0007] Specific implementation mode two: combination figure 1 , figure 2 , image 3 , Figure 4 Describe this embodiment, the difference between this embodiment and specific embodiment 1 is: the diameter of the oxidant bubble in this embodiment is 3mm, the volume percentage of described ozone and oxygen is: ozone: 5%, oxygen: 95% The volume percent of described ozone and air is: ozone: 5%, air: 95%, and the concentration that ozone feeds is 3.0mg / L, and keeping water temperature is 25 ℃, and the flow velocity of water flow through porous medium filler 1-3 is 0.25m / s.

specific Embodiment approach 3

[0008] Specific implementation mode three: combination figure 1 Describe this embodiment, the difference between this embodiment and specific embodiment 1 is: in this embodiment, the porous medium filler 1-3 is placed on the bottom wall 1-1-3 of each unit cell 1-1. 1 on. Arranging the porous medium filler 1-3 on the bottom wall 1-1-1 in each unit pool 1-1 can change the flow line of the water flow and avoid the occurrence of short flow, thereby prolonging the ozone contact oxidation pool 1. Pollutants contact reaction time with ozone.

[0009] Specific implementation mode four: combination figure 2 Describe this embodiment, the difference between this embodiment and specific embodiment 1 is: in this embodiment, the porous media filler 1-3 is placed on the side wall 1-1-1 of each unit cell 1-1. 2 on. Arranging the porous media filler 1-3 on the side wall 1-1-2 in each unit pool 1-1 can change the flow line of the water flow and avoid the occurrence of short flow, thereby p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com