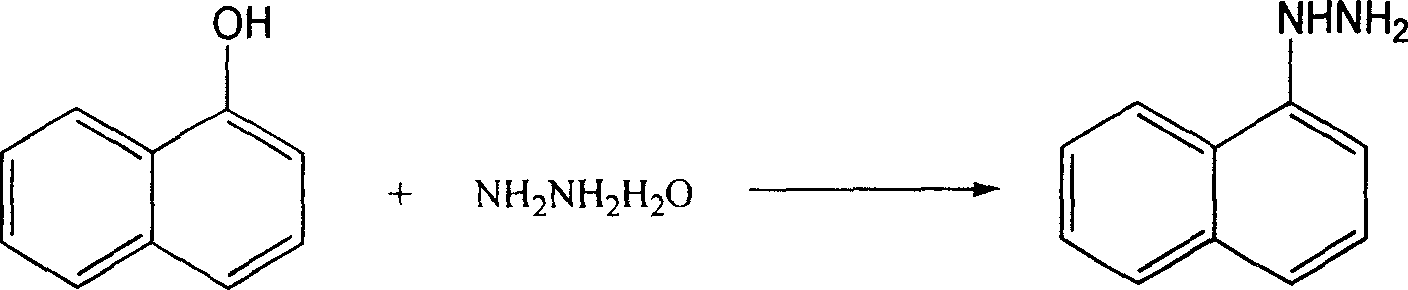

1-naphthylhydrazine preparation method

A technology of naphthalene hydrazine and naphthol, which is applied in the field of preparation of 1-naphthyl hydrazine, can solve the problems of difficulty in guaranteeing purity, low yield, pollution, etc., and achieve the effects of no environmental pollution, high yield, and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Add 25 grams of 1-naphthol (industrial product), 200 grams of hydrazine hydrate aqueous solution (weight concentration is 80%) and 20 grams of sodium bisulfite in a 500 milliliter three-necked flask with stirring and reflux condenser, heat under nitrogen protection React at 120-130° C. for 30 hours, then cool, filter, rinse with deionized water until the pH value is basically constant, and dry the filter cake to obtain 18 grams of white solid 1-naphthylhydrazine with a yield of 67%. Recrystallization from a solution of ethanol / water=2:1 can give crystal 1-naphthylhydrazine.

Embodiment 2

[0018] Add 50 grams of 1-naphthol (industrial product), 400 grams of hydrazine hydrate aqueous solution (50% by weight) and 20 grams of ammonium chloride in a 1000 milliliter three-necked flask with stirring and reflux condenser, and heat to React at 130-140°C for 40 hours, slowly add 200 ml of ice water while stirring, continue stirring for half an hour, filter, wash with water, and dry to obtain 32 g of white solid 1-naphthylhydrazine with a yield of 61%.

Embodiment 3

[0020] Add 50 grams of 1-naphthol (industrial product), 200 grams of hydrazine hydrate aqueous solution (weight concentration is 80%) and 1 gram of molecular sieves in the 1000 milliliters three-neck flasks with stirring and reflux condenser, be heated to 130- React at 140°C for 30 hours, filter molecular sieves, filter after cooling, rinse with deionized water until the pH value is basically constant, and dry the filter cake to obtain 47 grams of white solid 1-naphthylhydrazine with a yield of 87%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com