Patents

Literature

68 results about "1-Naphthalene" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

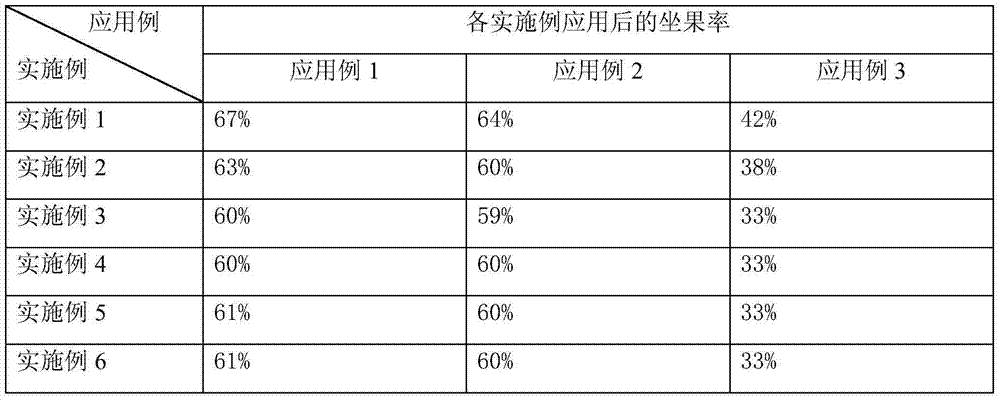

Growth regulator for improving fruit setting rate of peaches and regulating method

ActiveCN103918650AReduce economic costsMake up for the lack of endogenous hormonesPlant growth regulatorsBiocideFruit setPeach orchard

The invention relates to the technical field of fruit growing and in particular relates to a growth regulator for improving the fruit setting rate of peaches and a regulating method. The growth regulator comprises the following components of gibberellin and auxin, wherein the auxin may be one of 1-Naphthalene acetic acid, sodium alpha-naphthyl acetate, indoleacetic acid, phenylacetic acid, indolebutyric acid, indoleacetic acid and 2,4-dichlorphenoxyacetic acid, and the growth regulator is sprayed after the peaches bloom. The growth regulator provided by the invention is easy to obtain and prepare and low in economic cost, and can effectively remedy deficiency of endogenous hormone caused by poor fertilization of peaches; the method for applying the growth regulator provided by the invention is simple and convenient and easy to operate and control, effectively solves the problem that in the growing of peaches, the fruit setting rate is influenced by abnormal weather in a flowering phase, shriveled flower buds, overly rapid warming and the like, improves the fruit setting rate by more than 34 times, and is obvious in effect and applicable to popularization and application in the production of peaches in common peach orchards, green houses and other facilities.

Owner:CHANGLI INST OF POMOLOGY HEBEI ACADEMY OF AGRI & FORESTRY SCI

Root inducing agent and its preparation and use

InactiveCN1504088AImprove transplant survivalHigh activityBiocideAnimal repellantsAcetic acidGrowth plant

The invention relates to a root accelerant for accelerating the growth of new roots for plant seeds, root system or cottage organs, which comprises plant growth regulator, macronutrient and minute quantity nutriment elements, wherein said plant growth regulator includes DPC, 1-naphthalene acetic acid, indoxylic butanoic acid, 6-benzyl amino leucon and 2,4-Dichlorophenoxyacetic acid. The invention also relates to the process and usage of the root accelerant.

Owner:INST OF COTTON RES CHINESE ACAD OF AGRI SCI +1

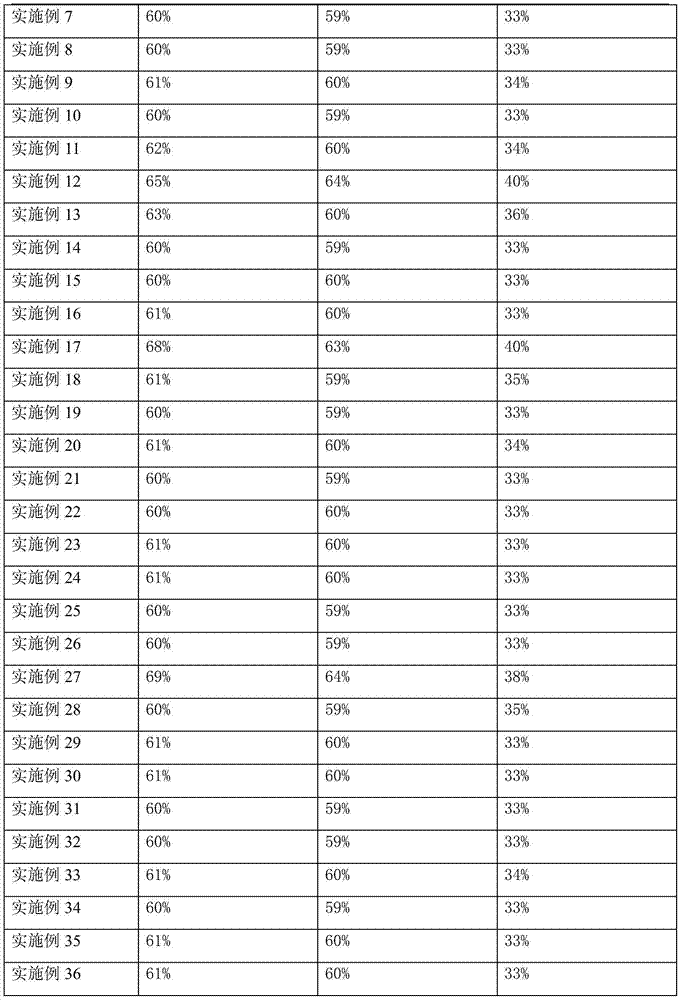

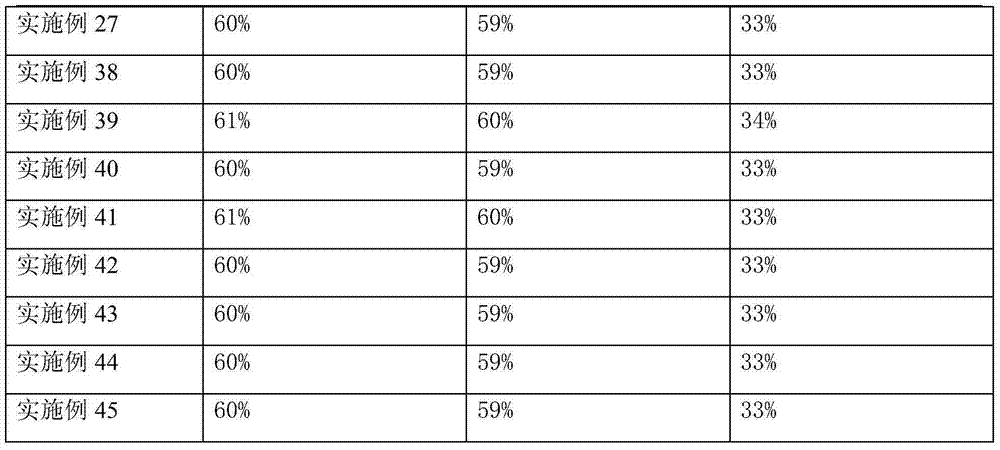

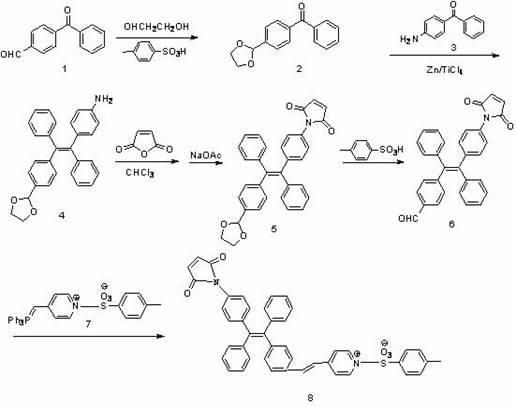

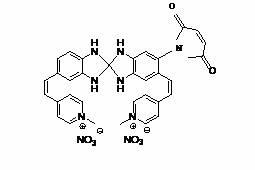

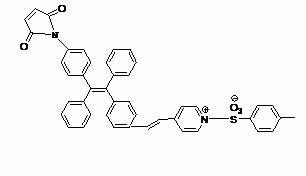

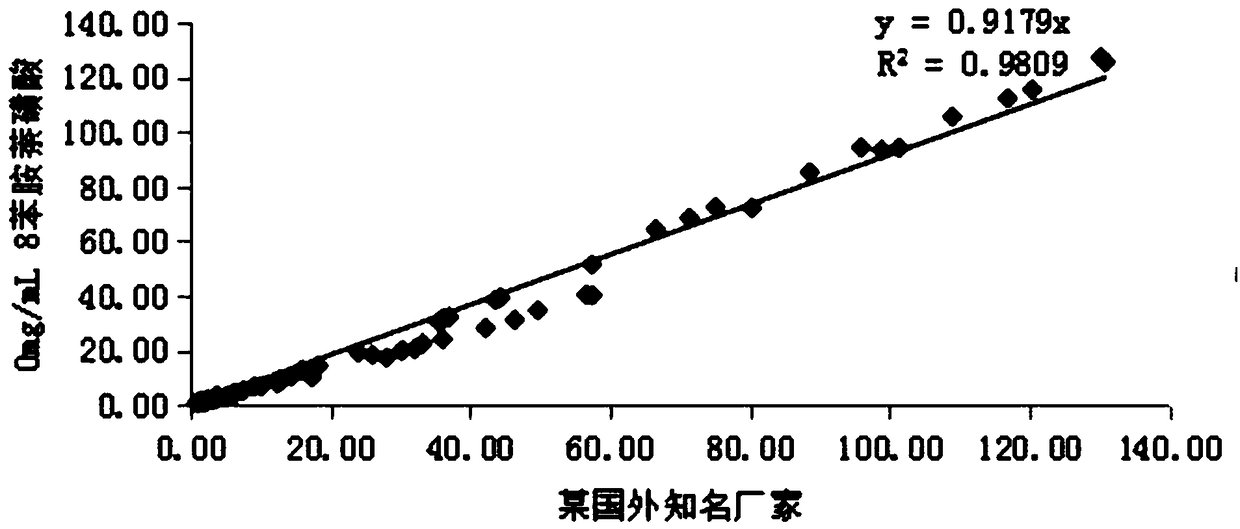

A method for monitoring the aggregation process of β-amyloid protein using aggregation-induced luminescence

InactiveCN102279270AHigh selectivityIncreased hydrophobicity of the environmentBiological testingAggregation-induced emissionCell Aggregations

The invention discloses a method for monitoring beta amyloid protein aggregation process by aggregation-induced emission, belonging to the technical field of biomedical research and clinical detection. With the method, the high affinity between sulfydryl on cysteine and maleimide is utilized to specially combine the beta amyloid protein on an aggregation-induced emission probe. The beta amyloid protein aggregation process is monitored on the basis of aggregation-induced emission enhancement phenomenon. The method has the advantages of high sensitivity, high selectivity, good stability, low manufacture cost and the like and is easy to control. The A beta42 and A beta40 contents can be monitored in a micromole, even a nano-mole level, the detection speed of the method is improved by 15 times if being compared with that of the detection method which utilizes probes, such as ANS (8-aniline-1-naphthalene sulfonic acid) and the like. The beta amyloid protein aggregation process can be qualitatively and quantitatively monitored, the method has a good application prospect if being applied to the pathologic diagnosis of latent patients suffering from senile dementia.

Owner:SHANGQIU NORMAL UNIVERSITY

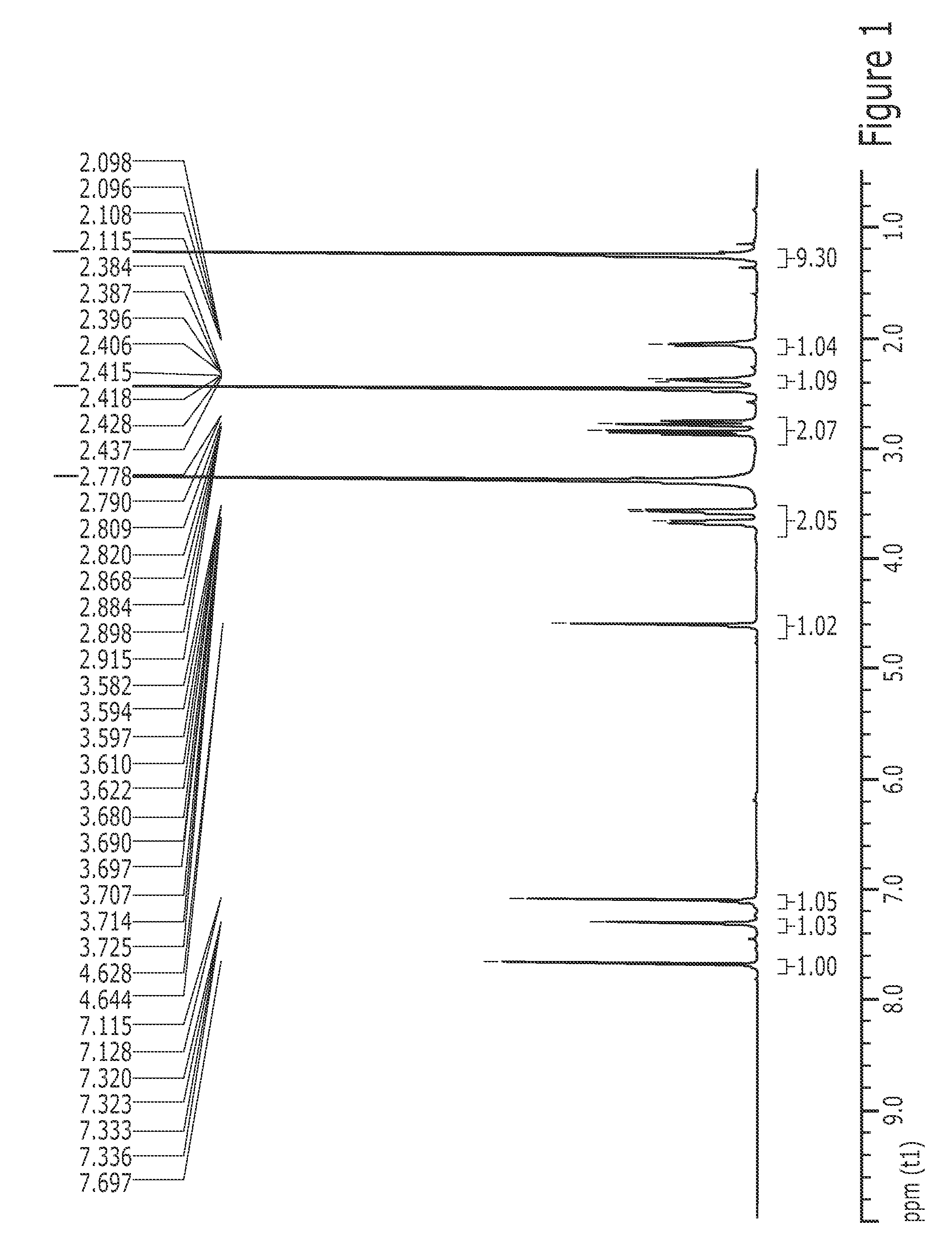

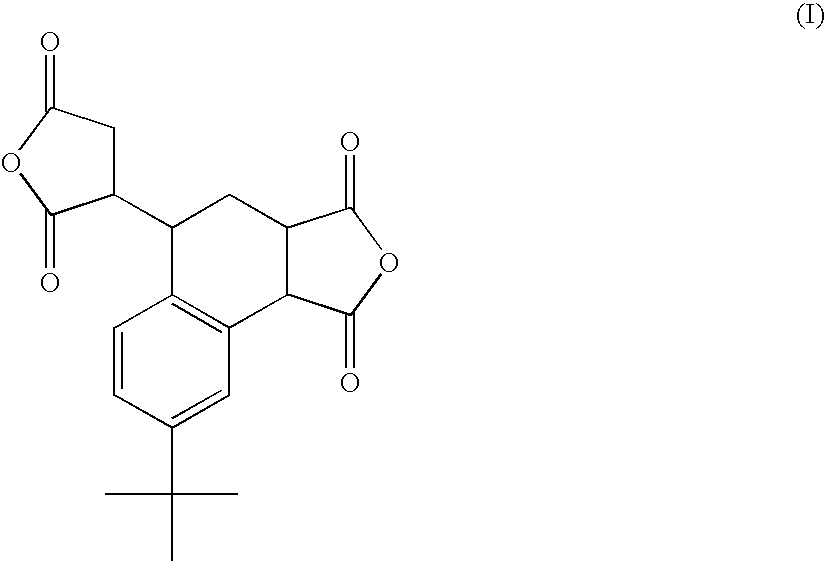

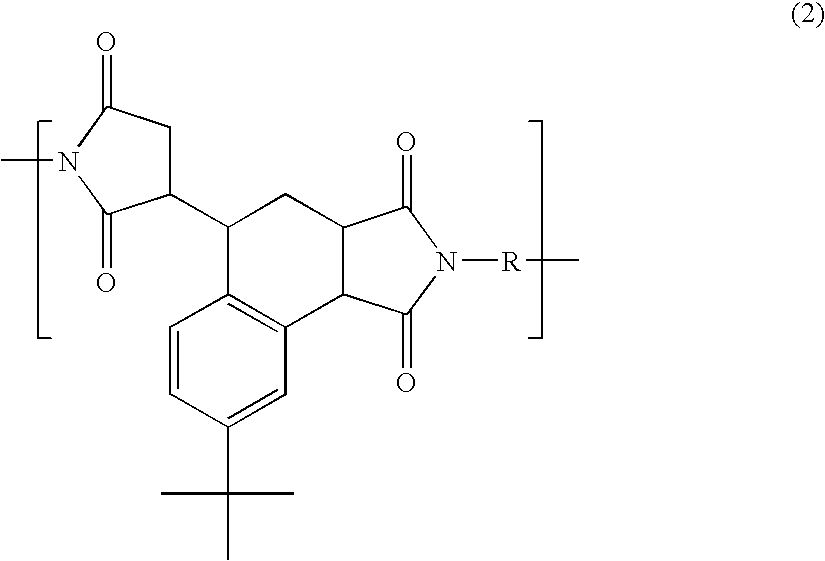

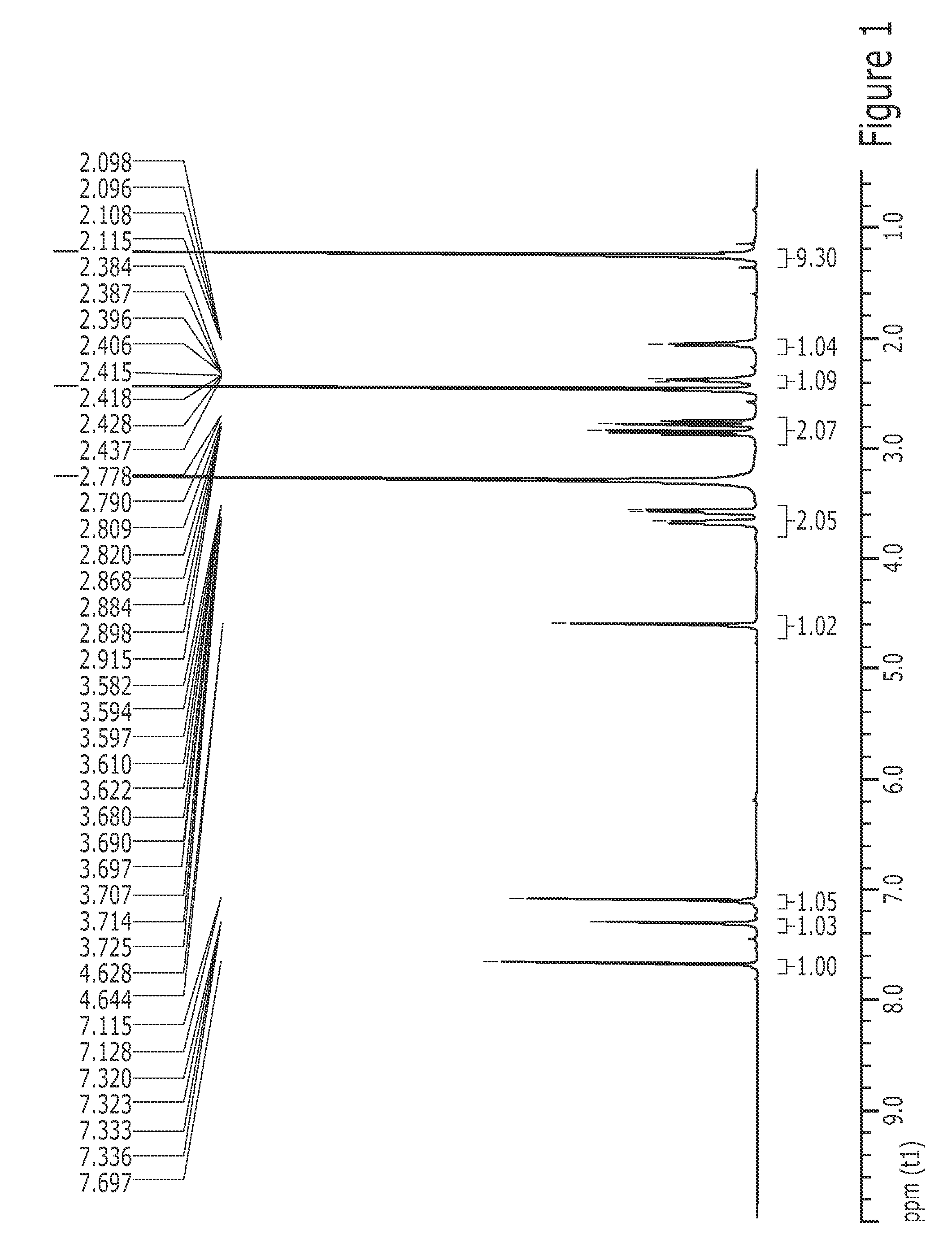

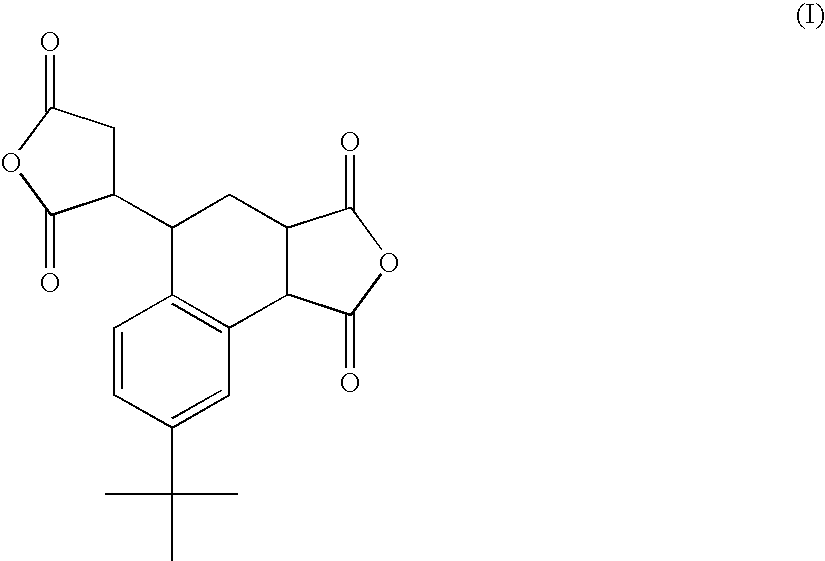

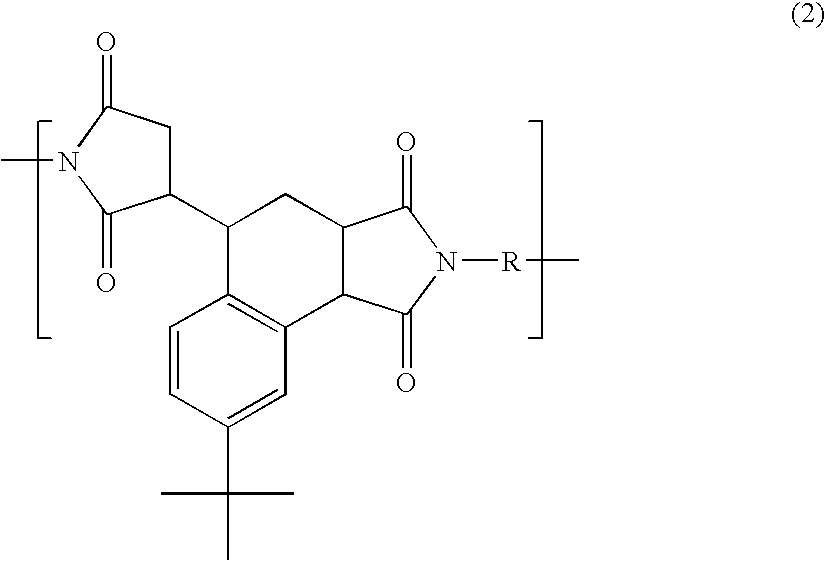

3,4-Dicarboxy-1,2,3,4-tetrahydro-6-t-butyl-1-naphthalene-succinic Dianhydride and Liquid Crystal Aligning Agent Comprising Polyimide Resin Prepared from the Dianhydride

InactiveUS20090299014A1Improve electrical performanceGood washing stabilityLiquid crystal compositionsOrganic chemistryCrystallographyHydrogen

3,4-Dicarboxy-1,2,3,4-tetrahydro-6-t-butyl-1-naphthalene-succinic dianhydride is provided. The tetracarboxylic dianhydride is represented by Formula 1, which is described in the specification. Further provided is a liquid crystal aligning agent comprising a polyimide prepared using the tetracarboxylic dianhydride and a solvent. Further provided is a liquid crystal alignment layer formed using the liquid crystal aligning agent. The liquid crystal alignment layer exhibits excellent electro-optical properties and good processability in terms of printability.

Owner:CHEIL IND INC

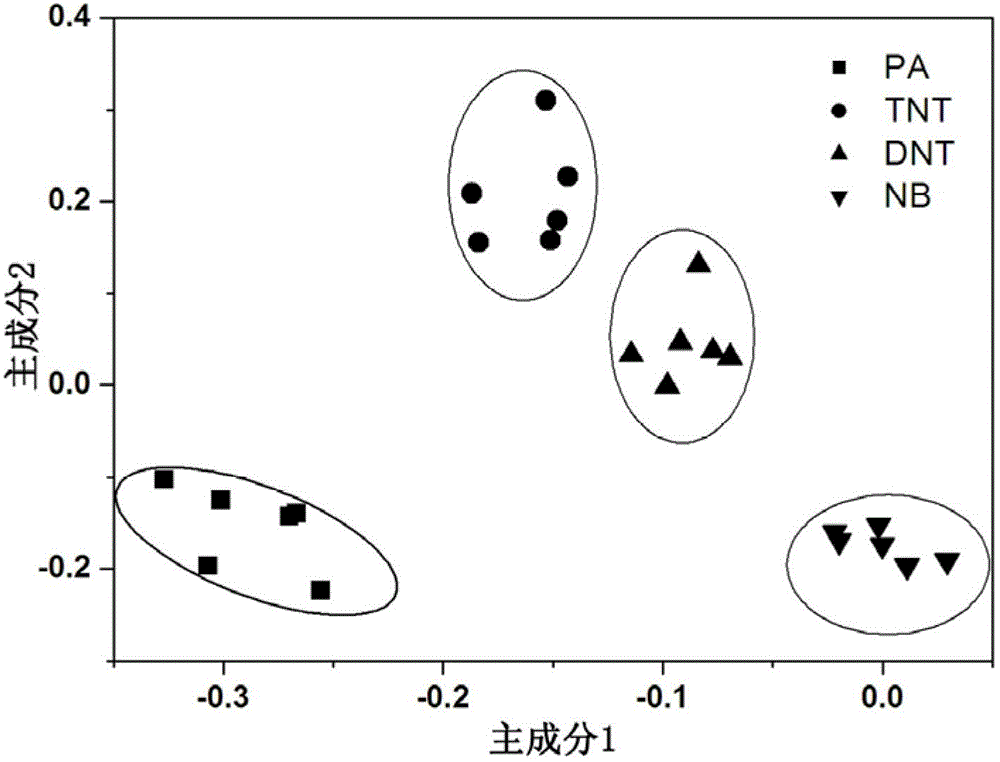

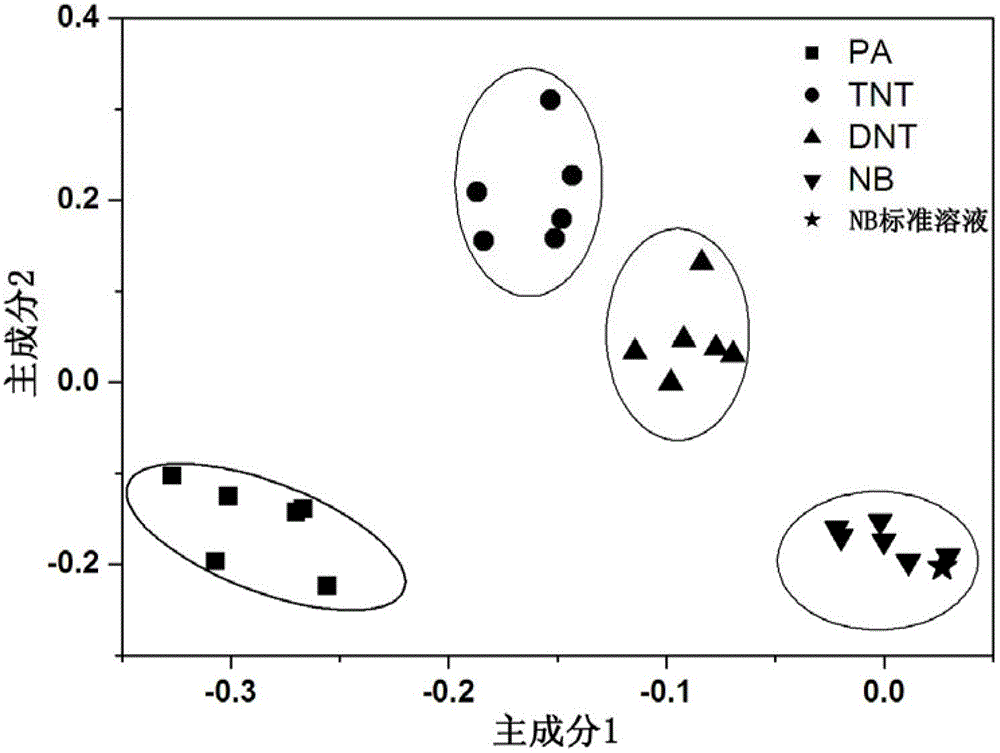

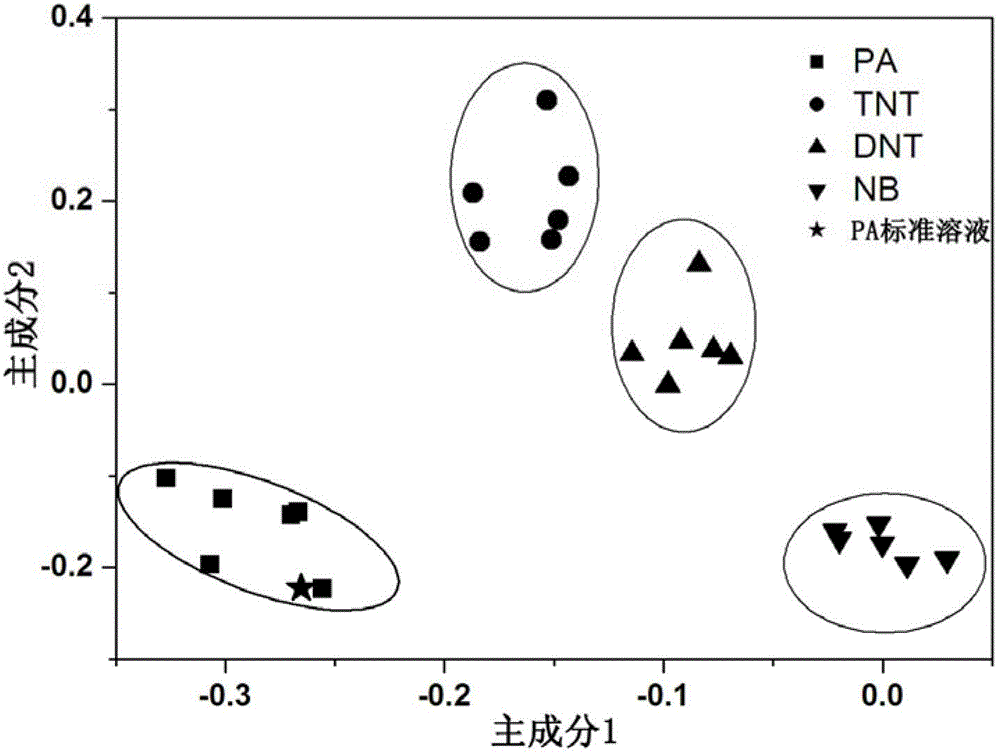

Identification detection method for nitro-aromatic explosives

The invention relates to an identification detection method for nitro-aromatic explosives. Sensing thin films of the same fluorescent unit connected through different connecting arms have different quenching responses to nitro-aromatic compounds, and six fluorescent sensing thin films modified by 5-dimethyl amino-1-naphthalene sulfonyl taking different diamines as connecting arms are used for further analyzing quenching response results by using a weighted principal component analysis method to learn about that four standard nitro-aromatic explosives 4,6-trinitrotoluene, 2,4,6-trinitrophenol, 2,4-dinitrotoluene and nitrobenzene are in different areas in coordinates to further fulfill the aim of identifying the four nitro-aromatic explosives in an explosive and make the identification detection of the four nitro-aromatic explosives in the explosive possible. According to the identification detection method, the nitro-aromatic compounds can be well responded and sensitively detected.

Owner:SHAANXI NORMAL UNIV

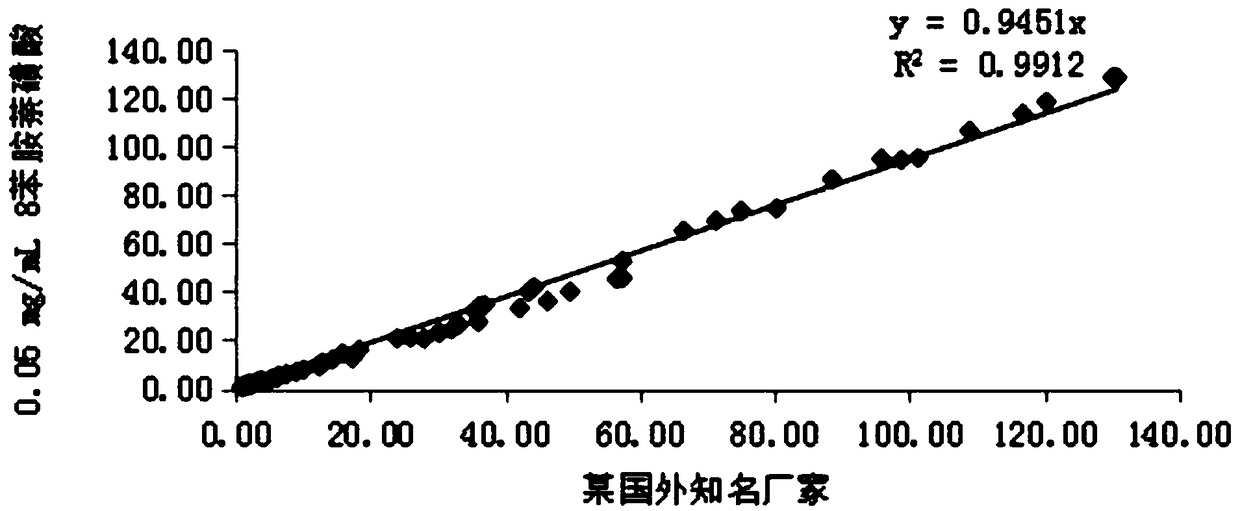

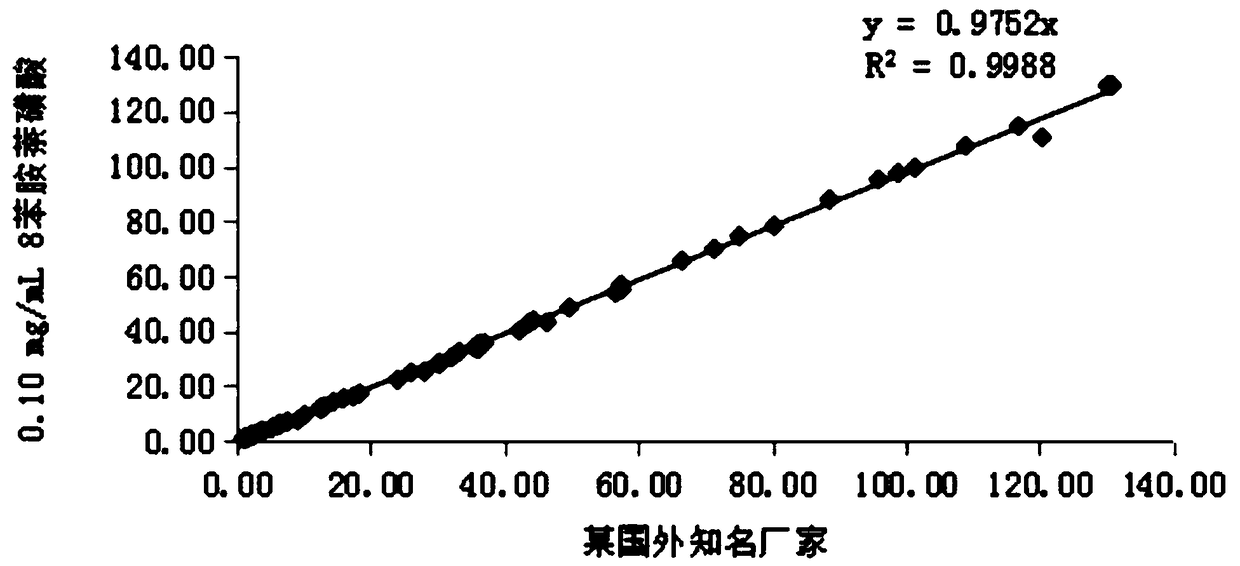

Glycocholic acid detection kit

PendingCN109444399ASimple preparation stepsLow costDisease diagnosisColor/spectral properties measurementsLatex particleAniline

The invention provides a glycocholic acid detection kit and a preparation method of a glycocholic acid-protein conjugate and glycocholic acid antibody coated rubber latex particles in the glycocholicacid detection kit. According to the glycocholic acid detection kit, glycocholic acid is detected by a competition method, 8-aniline-1-naphthalene sulfonic acid is added into the kit, so that the analysis sensitivity and precision of the kit are obviously improved, the linear range of detection is widened, preparation steps of specific substances in the kit are simple, and the kit is low in cost and more applicable to industrial production and clinic application.

Owner:ZYBIO INC

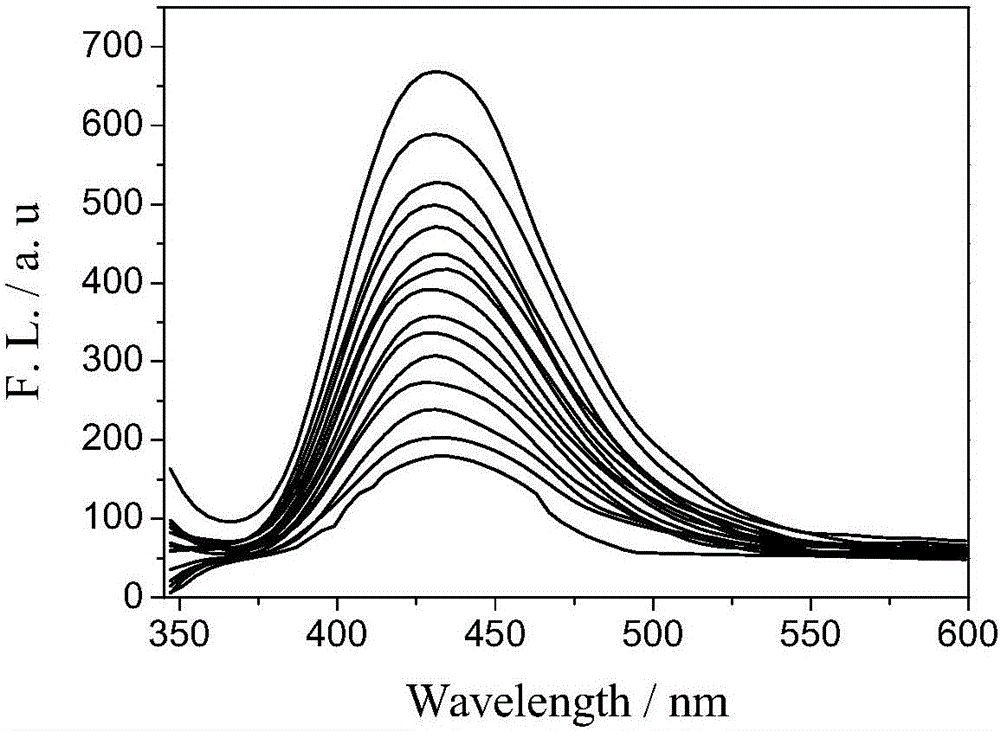

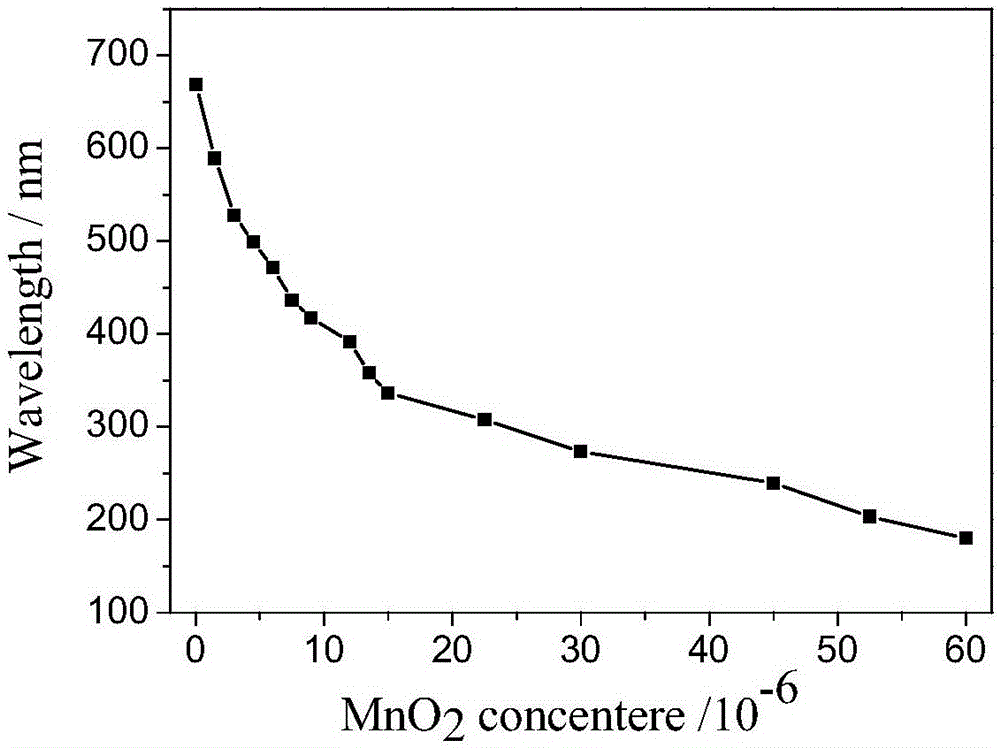

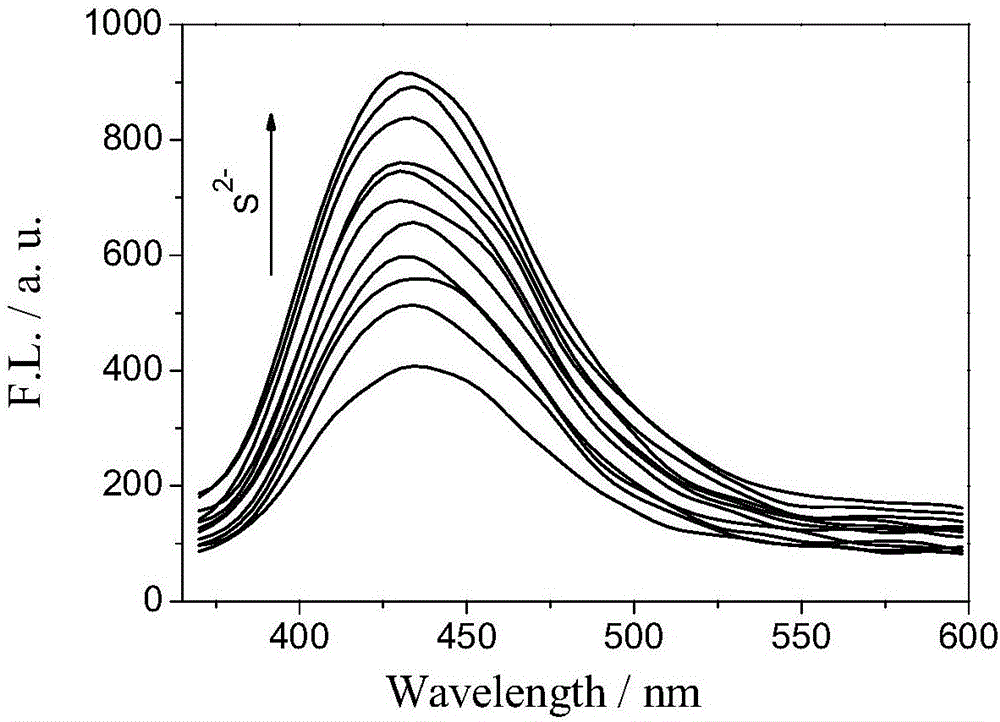

Fast sulfide ion test method

ActiveCN106442448ALarge specific surface areaRich structural diversityFluorescence/phosphorescenceSulfonateLinear relationship

The invention provides a fast sulfide ion test method. The method uses a property of ANS that the fluorescence of 4-Amino-1-Naphthalene sulfonate (ANS) can be effectively quenched by MnO2 nano-material to prepare the ANS / MnO2 composite system. When tiny portion of S<2-> is added in the system, because the oxidation-reduction reaction occurs between the S<2-> and MnO2 to generate divalent manganese ions in the solution, thus enhancing the fluorescence intensity of the ANS, and the increase of the fluorescence intensity is in a linear relationship with the S<2-> ions concentration, thus achieving the test of S<2-> ion. Compared with prior art the method has the advantages of being simple in operation and being able to test the S<2-> ion in a fast and real time mode.

Owner:广西弘远环境监测有限公司

Non-solvated crystals as well as preparation method and application thereof

The invention relates to non-solvated crystals A, B and C of N-(2-aminophenyl)-6-(7-methoxyquinoline-4-oxo)-1-naphthalene amide and a preparation method of non-solvated crystals A, B and C, also relates to pharmaceutical composition containing the crystals and an application of the crystals in preparation of a drug for treating diseases related to abnormal activities of protein kinase or abnormalactivities of histone deacetylase.

Owner:SHENZHEN CHIPSCREEN BIOSCIENCES CO LTD

3,4-dicarboxy-1,2,3,4-tetrahydro-6-t-butyl-1-naphthalene-succinic dianhydride and liquid crystal aligning agent comprising polyimide resin prepared from the dianhydride

InactiveUS7901745B2Maintain good propertiesImprove solubilityLiquid crystal compositionsOrganic chemistryCrystallographyOptical property

3,4-Dicarboxy-1,2,3,4-tetrahydro-6-t-butyl-1-naphthalene-succinic dianhydride is provided. The tetracarboxylic dianhydride is represented by Formula 1, which is described in the specification. Further provided is a liquid crystal aligning agent comprising a polyimide prepared using the tetracarboxylic dianhydride and a solvent. Further provided is a liquid crystal alignment layer formed using the liquid crystal aligning agent. The liquid crystal alignment layer exhibits excellent electro-optical properties and good processability in terms of printability.

Owner:CHEIL IND INC

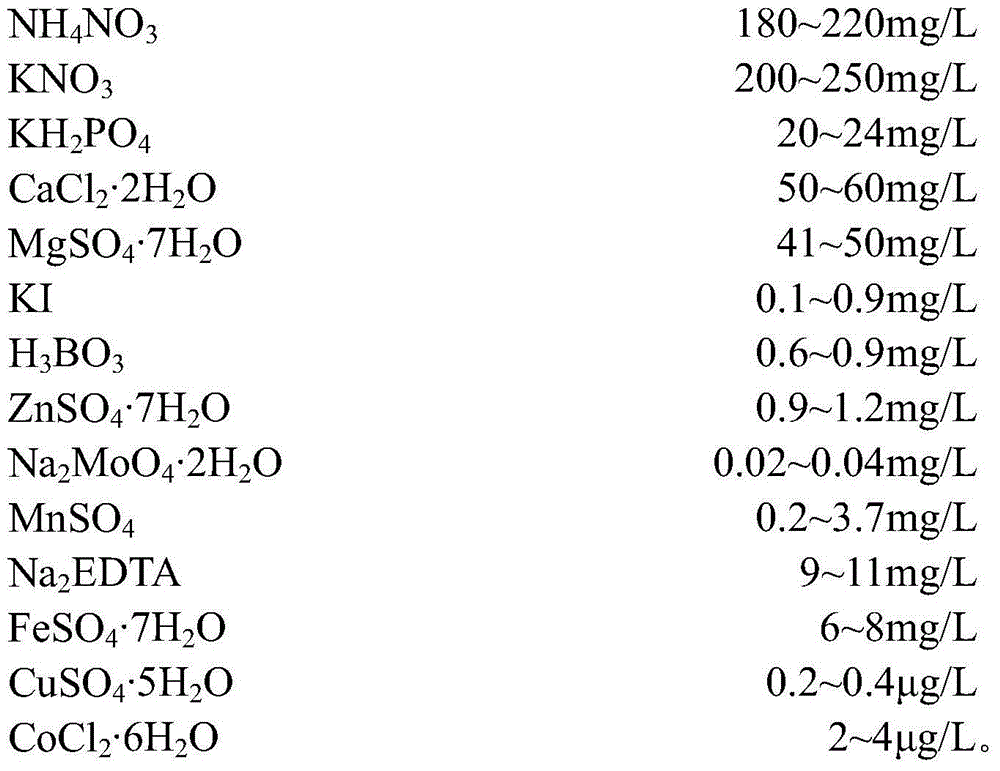

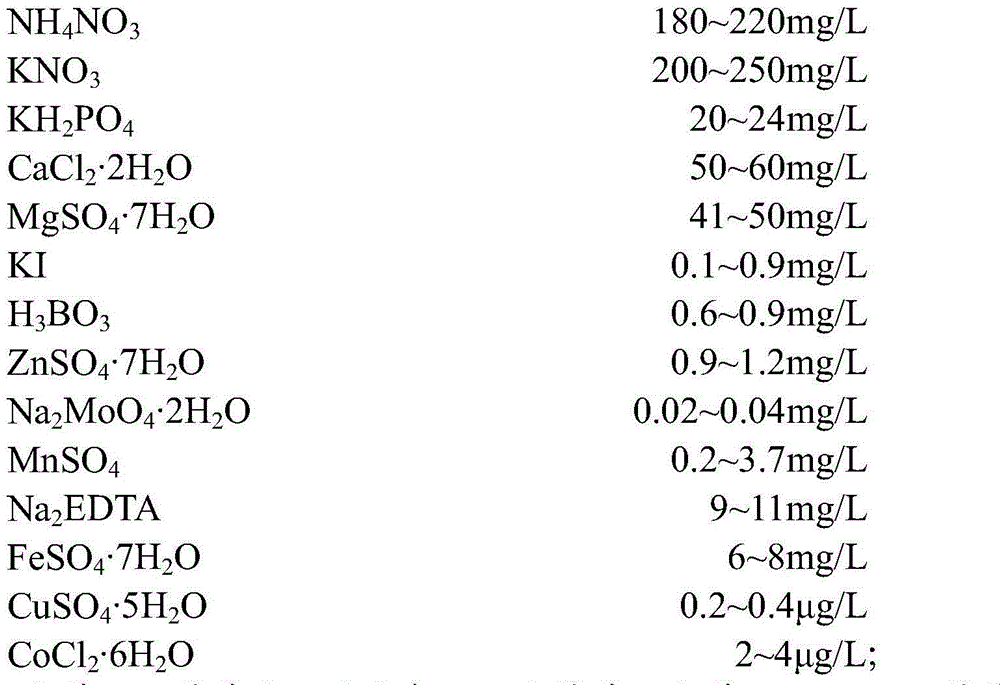

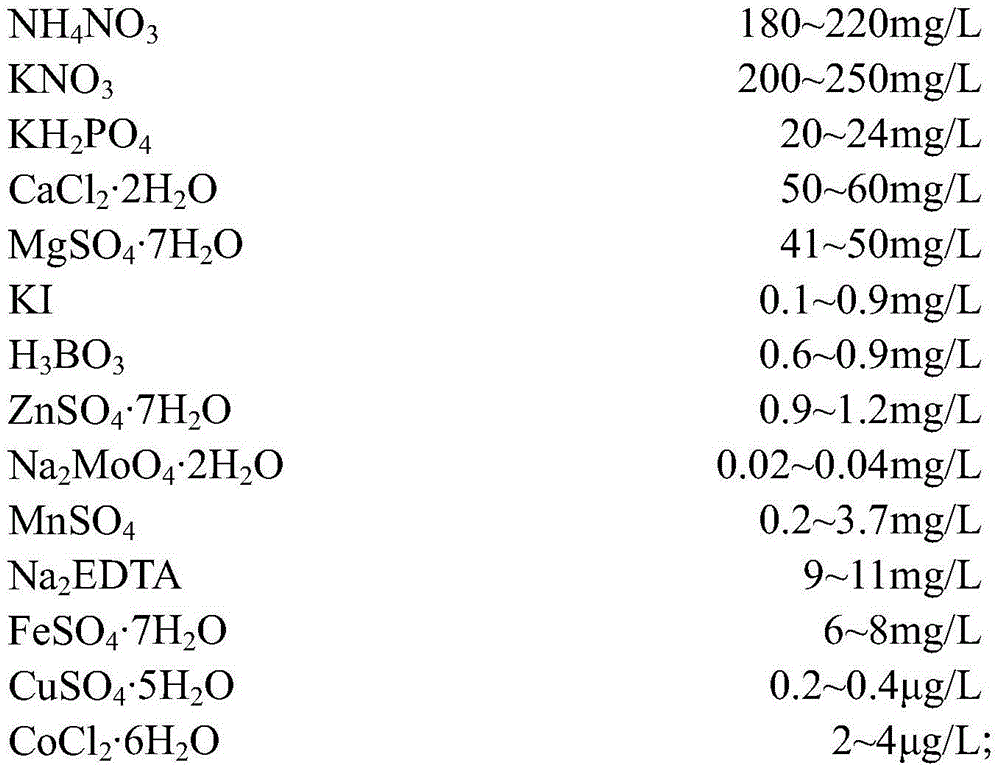

Culture medium for dendrobium tissue cultivation

InactiveCN104206282APromote growthComponents are easy to obtainHorticulture methodsPlant tissue cultureAcetic acidSugar

The invention discloses a culture medium for dendrobium tissue cultivation. MS (Murashige and Skoog) culture medium is served as a basal culture medium and added components comprise 1-naphthalene acetic acid, 6-benzylaminopurine, proline, sugar, bananas and agar. According to the culture medium, the MS culture medium is served as the basal culture medium, other components are added, utilized components are easy to obtain, costs are low, the dendrobium grows well, the yield and the quality are greatly improved, and the culture medium can be applied to dendrobium research, development and fields in production and is particularly applicable to large scale industrialized production.

Owner:江苏神草生物科技有限公司

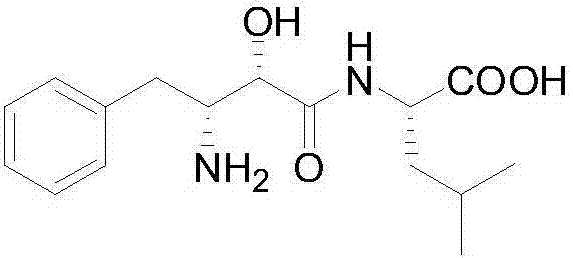

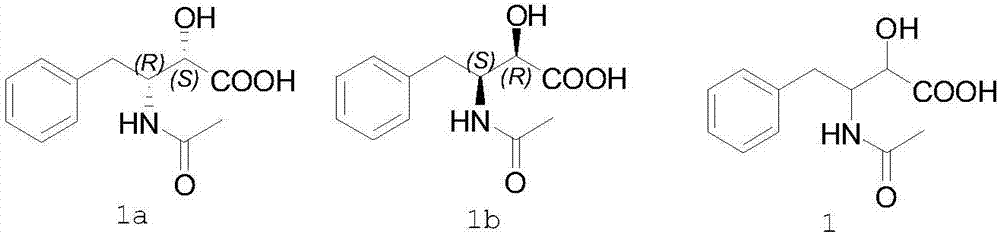

Preparation method of ubenimex intermediate (2S,3R)-3-acetamido-2-hydroxyl-4-phenylbutyric acid

InactiveCN107098827AHigh purityIncrease production capacityCarboxylic acid amides optical isomer preparationPhenylbutyrateEthylamine

The present invention provides a method for preparing an ubenimex intermediate (2S,3R)-3-acetamido-2-hydroxyl-4-phenylbutyric acid by using an organic alkali as a resolving agent, wherein the organic alkali is selected from S-1-naphthalene ethylamine, (S)-1-(2-naphthyl)ethylamine, L-phenylglycinol, and L-phenylalaninol. According to the present invention, the preparation method has advantages of good ubenimex intermediate purity, high yield, simple operation and good reproducibility, and is suitable for industrial production.

Owner:CHANGZHOU AINUOXINRUI PHARMA LTD

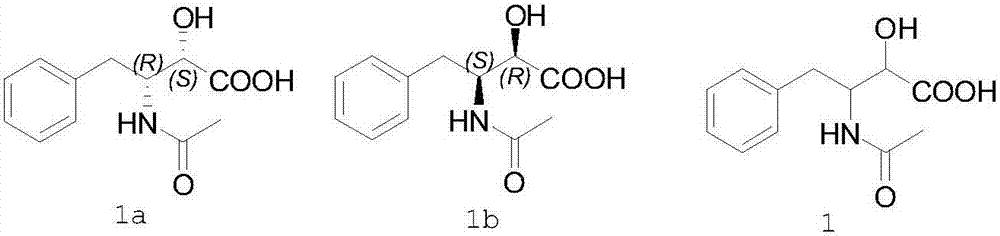

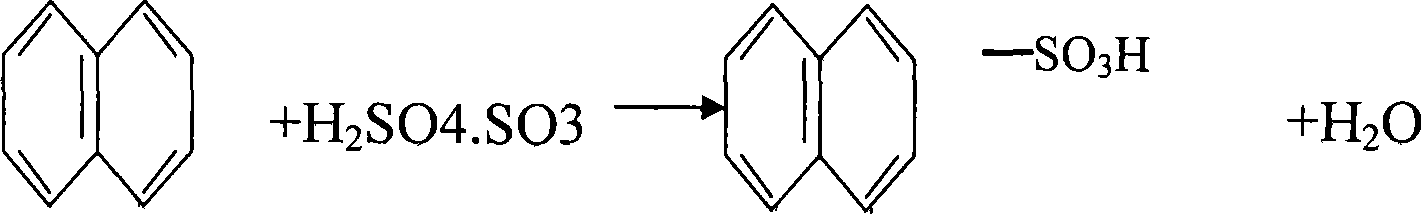

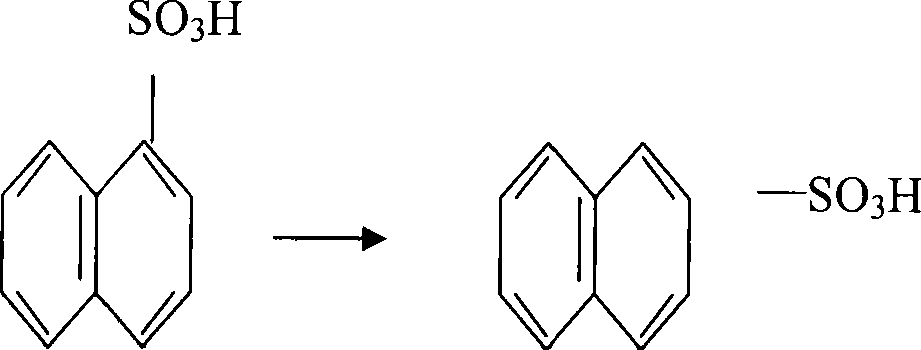

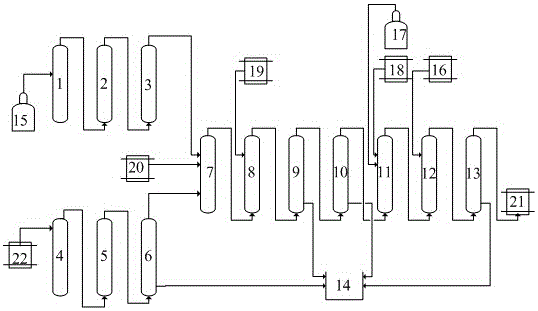

Naphthalene sulfonating method for coproducing 1-naphthol and 2-naphthol

InactiveCN108530271AIncrease productionHigh purityOrganic compound preparationSulfonic acids salts preparationDistillationSulfite salt

The invention discloses a naphthalene sulfonating method for coproducing 1-naphthol and 2-naphthol. The naphthalene sulfonating method comprises the following steps: directly neutralizing after carrying out sulfonating reaction: adding a sodium sulfite solution of which the concentration is 12 percent into a neutralizing kettle, then adding a naphthalene sulfonic acid molten material, reacting byregulating PH (Potential of Hydrogen) to be 1 to 2, heating the solution to be 105 DEG C, keeping warm for 15 minutes, and regulating the PH of the neutralizing kettle to be 7 to 8 after completing reaction; after neutralizing, sequentially carrying out naphthalene blowing, cooling crystallization, filtering, alkaline fusion, diluting, acidifying, boiling and stratifying, dewatering and drying and distillation separation, thus generating 1-naphthol and 2-naphthol. According to the naphthalene sulfonating method disclosed by the invention, a 1-naphthalene sulfonic acid isomer in a sulfonatingproduct does not need to be removed, 1-naphthol and 2-naphthol are simultaneously obtained through co-production, and the yield and the purity of 1-naphthol and 2-naphthol are effectively increased through specific production steps; a hydrolysis step is omitted, generation of wastewater during production is reduced, a production technology is simplified, and the production cost is reduced.

Owner:山西豪仑科化工有限公司

Modified zeolite functional material for fixing benzene degrading bacteria and preparation method thereof

InactiveCN106701733AHigh mechanical strengthEnhanced mass transferWater contaminantsOn/in inorganic carrierNitroureaPyran

The invention discloses a modified zeolite functional material for fixing benzene degrading bacteria. Zeolite is modified by a mixed solution prepared from ammonium dihydrogen phosphate, tetrahydro-4H-pyran-4-one, 5-bromothiophen-2-formaldehyde, 2,5-dichloro-3-bromopyridine, tetrabromothiophene and 2-acetylene thiophene to obtain a substance B; the substance B is modified by a mixed solution prepared from 3-chloropyridazine, acetaldehyde phenylhydrazone, acetone oxime, guanidine nitrate and indole-6-carboxaldehyde to obtain a substance C; the substance C is modified by a mixed solution prepared from 3-formylthiophene, di-tert-amylbenzoquinone and 4-amino-3-hydroxy-1-naphthalene sulfonic acid to obtain a substance D; and the substance D is modified by a mixed solution prepared from propyl sulfate, 2-aminoanthraquinone and nitrourea to obtain a substance, namely the modified zeolite functional material for fixing the benzene degrading bacteria.

Owner:光合强化(北京)生物科技有限公司

105% acid sulfonation manufacturing technique of 2-naphthalenol

The present invention relates to a 105 percent acidic sulfonation production process of 2-naphthol, and belongs to the technical field of chemical production. In the process, molten refined naphthalene is added into a reaction still and is heated to be at the temperature between 135 DEG C and 140 DEG C, sulfuric acid of 105 percent is added within 30 minutes according to a mass ratio of 1.28 to 1, the temperature in the reaction still is raised to be 160 DEG C and maintained for 135 minutes, the sulphonation product with an acidity of 24 to 27 percent is prepared, and the next procedure is performed. The present invention solves the problems in the traditional process with sulphonation of sulphuric acid of 100 percent that water is generated in the process of substituting hydrogen on a double benzene nucleus with sulfonic group and has dilution effects on sulphuric acid, the substitution reaction is impeded, water becomes water vapor at the temperature of 160 DEG C which has hydrolysis effects on 1-naphthalene sulfonic acid and 2-naphthalene sulfonic acid, and the total yield rate of the sulfonation reaction is not high. And the present invention has the advantages that sulfuric acid of 105 percent is added, the sulfonation conversion and the product yield rate are improved, the generated naphthalene compounds and other byproducts are reduced, and the yield rate is improved by 1.1 percent.

Owner:湖北鑫慧化工有限公司

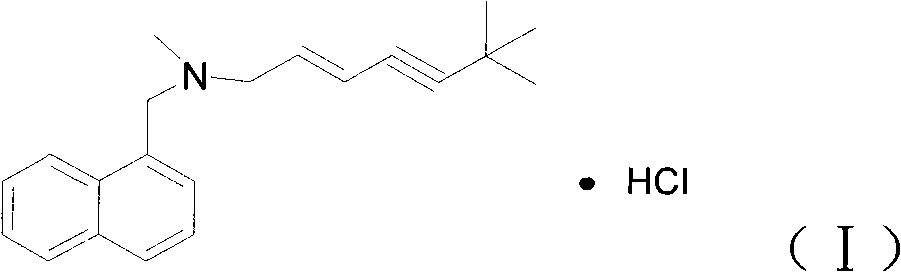

Preparation method of Terbinafine hydrochloride

InactiveCN101870655ARaw materials are cheap and easy to getThorough responseAntimycoticsPhysical/chemical process catalystsSodium iodideAlkyne

The invention relates to a preparation method of Terbinafine hydrochloride, which comprises the following steps: dissolving a certain amount of catalyst, i.e. sodium iodide (or potassium iodide) in an organic solvent, adding 1-chloro-6,6-dimethyl-2-heptylene-4-alkyne, sequentially adding alkali and N-methyl-1-naphthalene methylamine hydrochloride, carrying out condensation at 10-40 DEG C, salifying the obtained product in an alcohol system with hydrogen chloride to obtain the Terbinafine hydrochloride, and carrying out recrystallization in an alcohol / water mixed solution to obtain the qualified product. In the method, the raw materials are cheap and easily-acquired, the reaction is complete, and the reaction time is greatly shortened. Therefore, the method is completely suitable for industrialized mass production.

Owner:YANGTZE RIVER PHARMA GRP BEIJING HAIYAN PHARMA +1

Plant growth regulator for raising seedlings of eucalyptus dunnii maiden by cutting and method for raising seedlings of eucalyptus dunnii maiden by cutting

InactiveCN104082299AHigh rooting rateQuality improvementBiocidePlant growth regulatorsAcetic acidGrowth plant

The invention belongs to the field of plant propagation and discloses a plant growth regulator for raising seedlings of eucalyptus dunnii maiden by cutting and a method for raising the seedlings of eucalyptus dunnii maiden by cutting. The plant growth regulator for raising the seedlings of eucalyptus dunnii maiden by cutting provided by the invention comprises a first plant growth regulator and a second plant growth regulator, wherein the first plant growth regulator comprises 3-indolebutyric acid and 1-Naphthalene acetic acid, with the concentration of 1g / L-1.6g / L; the second plant growth regulator comprises 3-indolebutyric acid and 1-Naphthalene acetic acid, with the concentration of 0.83mg / L-2mg / L. After the first plant growth regulator provided by the invention is dipped with eucalyptus dunnii maiden cutting slips, the second plant growth regulator is used for pouring to preserve moisture; the plant growth regulator is used for continuously stimulating eucalyptus dunnii maiden to root so that the rooting rate of eucalyptus dunnii maiden cutting seedlings is obviously improved; root systems of the eucalyptus dunnii maiden cutting seedlings are developed and the quality is good; the plant growth regulator is suitable for industrialized production of the eucalyptus dunnii maiden cutting seedlings and is beneficial to propagation of eucalyptus dunnii maiden.

Owner:湖南省森林植物园

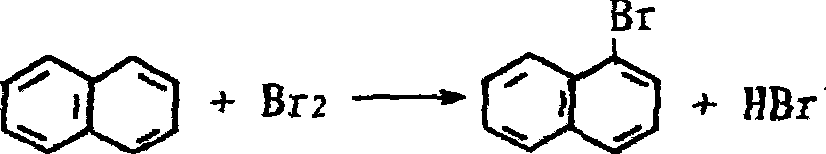

Preparation of 1-naphthalene bromide

ActiveCN101434513AImprove protectionReduce manufacturing costHalogenated hydrocarbon preparationFractionationEthane Dichloride

A preparing method of 1-naphthalene bromide adopts refined naphthalene and the mixed solvent of 1, 2-dutch liquid and 1, 1-dutch liquid. After being stirred, the mixture is heated up and dissolved; bromine is added, and the temperature is kept between 75 and 95 DEG C; refluence reaction is kept for 4 to 6 hours, and then the mixture is distilled; solvent is recycled; sodium hydroxide is added for neutralizing hydrogen bromide in the reaction solution; after a lye layer is separated, a crude product can be obtained; and after decompression and fractionation, a chemically pure 1-naphthalene bromide product can be obtained from the crude product. The method is beneficial for environmental protection and reduces the producing cost, and the quality of the product complies with the national chemically pure standard.

Owner:上海三爱思试剂有限公司

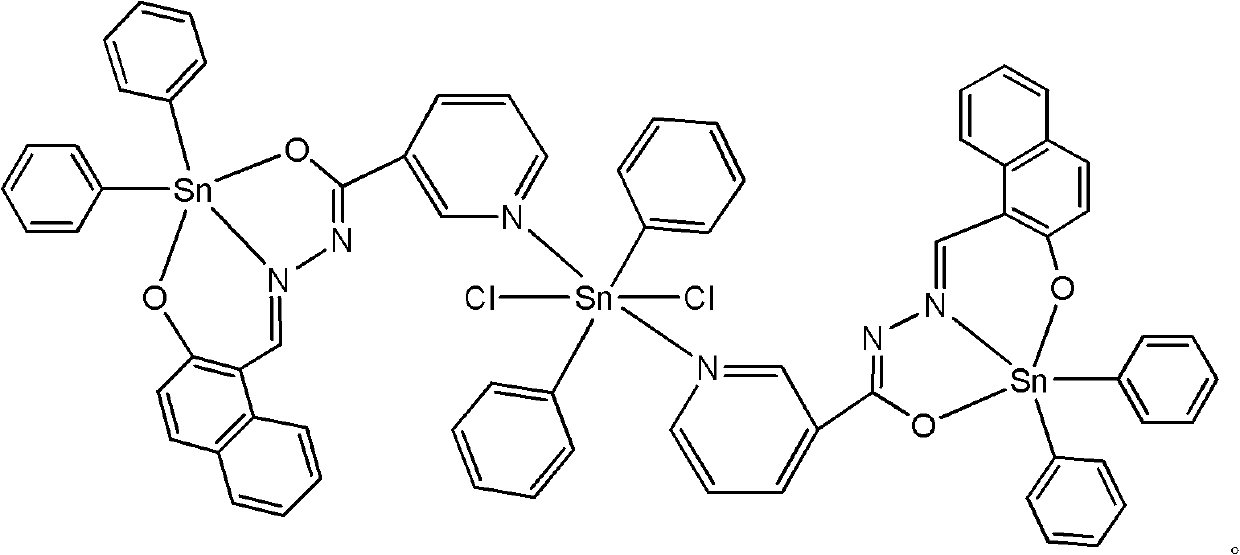

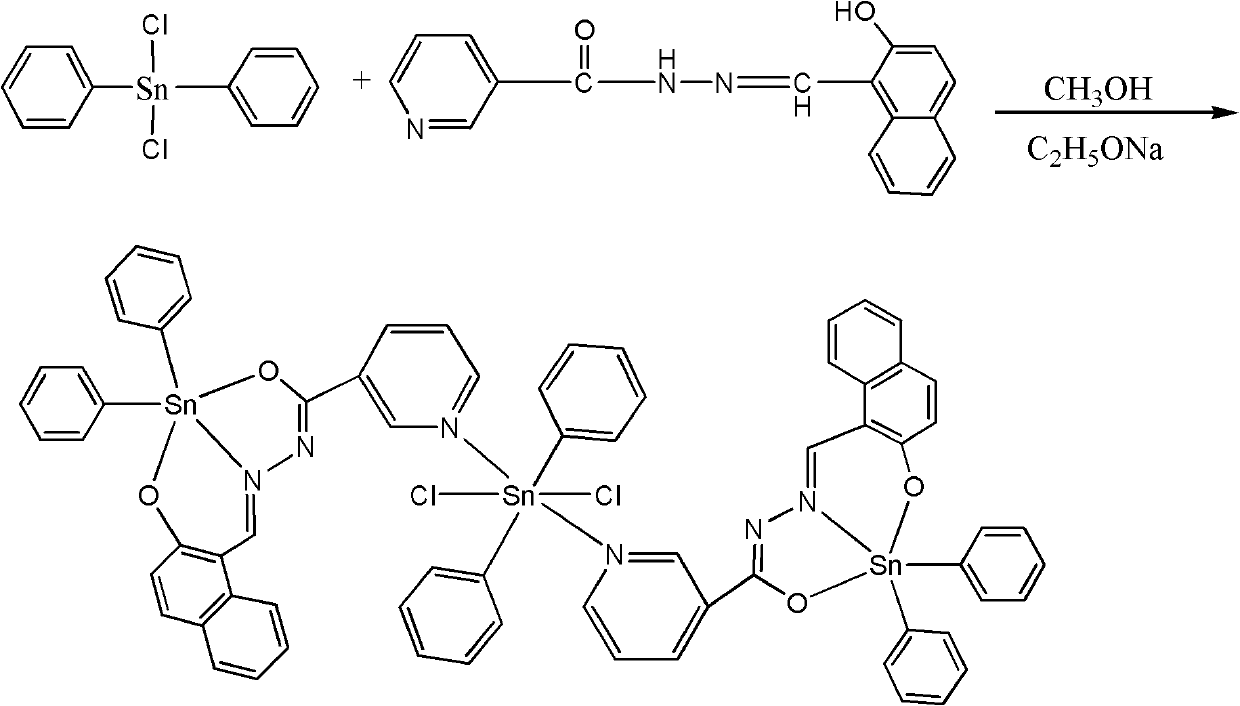

Dichlorodiphenyl-stannane complex and preparation method and application thereof

InactiveCN102127106AImprove herbicidal activityIncrease fat solubilityBiocideTin organic compoundsSolubilityEvaporation

The invention discloses a dichlorodiphenyl-stannane complex of which structural formula is shown as below. The preparation method comprises the following steps: adding 1mmol of 2-hydroxyl-1-naphthalene-3-pyridinecarboxamide, 1-1.5mmol of sodium ethoxide, 1-1.5mmol of dichlorodiphenyl-stannane and 20-30ml of methanol in a flask, stirring and refluxing at 60-70 DEG C for 6-7h, cooling to the room temperature, performing rotary evaporation to obtain yellow solid; and using dichloromethane-ethanol to recrystallize and obtain yellow transparent crystals, namely the dichlorodiphenyl-stannane complex. The organotin complex of the invention has higher herbicidal activity, can be used to prepare a herbicide for killing Echinochloa crusgalli, Digitaria sanguinalis, radish and rape. Compared with the common herbicide, the organotin complex of the invention is characterized by high herbicidal activity, good liposolubility, high water solubility, low cost, simple preparation method and the like, thus a new way is provided for the development of the herbicide.

Owner:LIAOCHENG UNIV

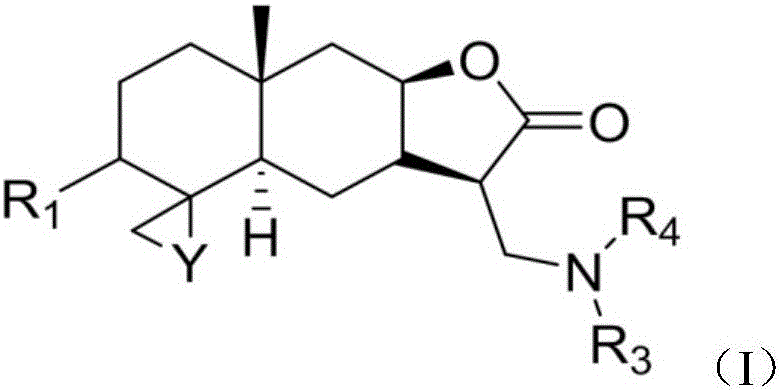

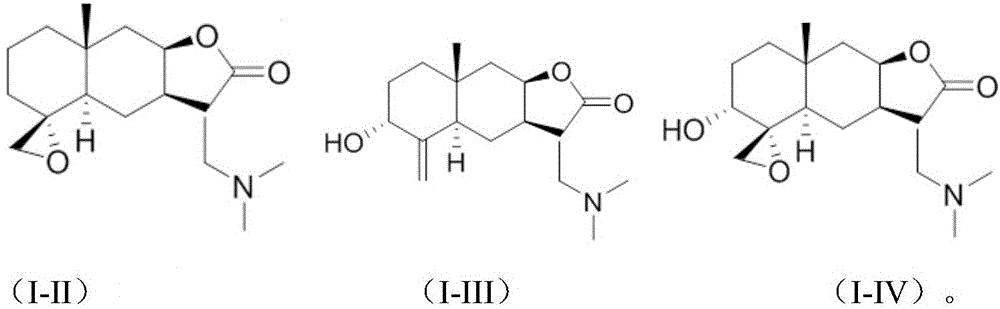

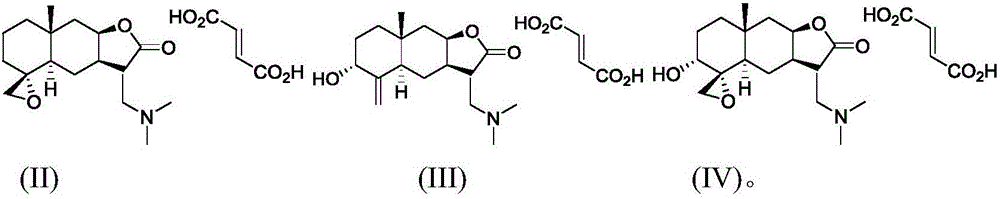

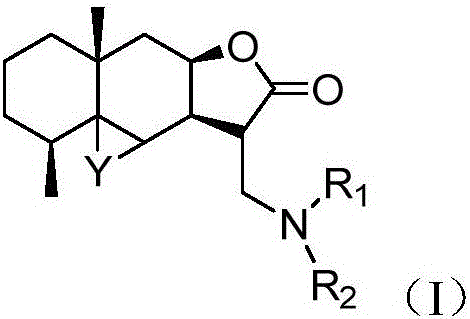

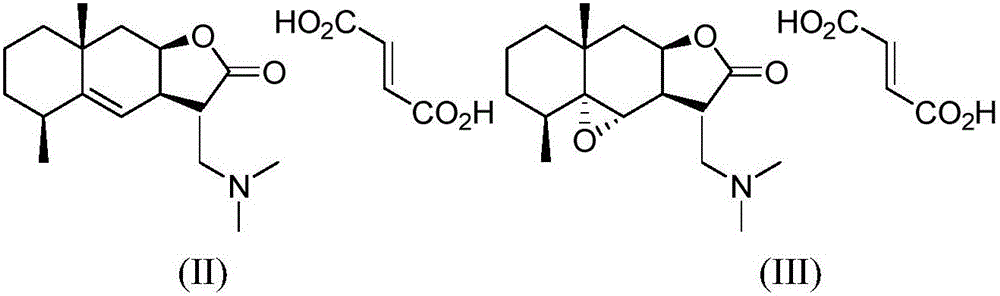

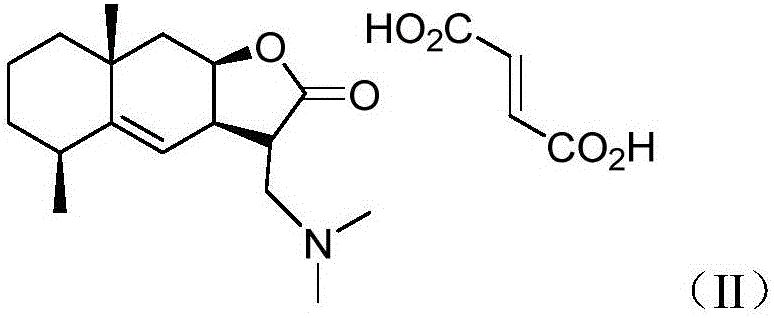

Isoalantolactone derivatives and their application in preparation of drugs for treating inflammatory bowel diseases

InactiveCN106474109AGood treatment effectOrganic active ingredientsOrganic chemistryBenzoic acidPhosphomolybdic acid

Isoalantolactone derivatives and their application in preparation of drugs for treating inflammatory bowel diseases are provided, and an isoalantolactone derivative shown as in formula (I) is provided; a salt-forming acid is an inorganic acid or organic acid, the inorganic acid is selected from hydrofluoric acid, hydrochloric acid, hydrobromic acid, hydroiodic acid, sulfuric acid, nitric acid, phosphoric acid, carbonic acid, bromic acid, seleninic acid, phosphomolybdic acid, phosphorus acid and sulfurous acid, and the organic acid is selected from citric acid, maleic acid, D-malic acid, L-malic acid, DL-malic acid, L-lactic acid, D-lactic acid, DL-acid, oxalic acid, methylsulfonic acid, pentanoic acid, oleic acid, lauric acid, p-methylbenzene sulfonic acid, 1-naphthalene sulfonic acid, 2-naphthalene sulfonic acid, phthalic acid, tartaric acid, malonic acid, succinic acid, fumaric acid, glycolic acid, mercapturic acid, glycine, creatine, sulfonic acid, nicotinic acid, picolimic acid, isonicotinic acid, and benzoic acid or substituted benzoic acid.

Owner:天承南运(天津)科技有限公司

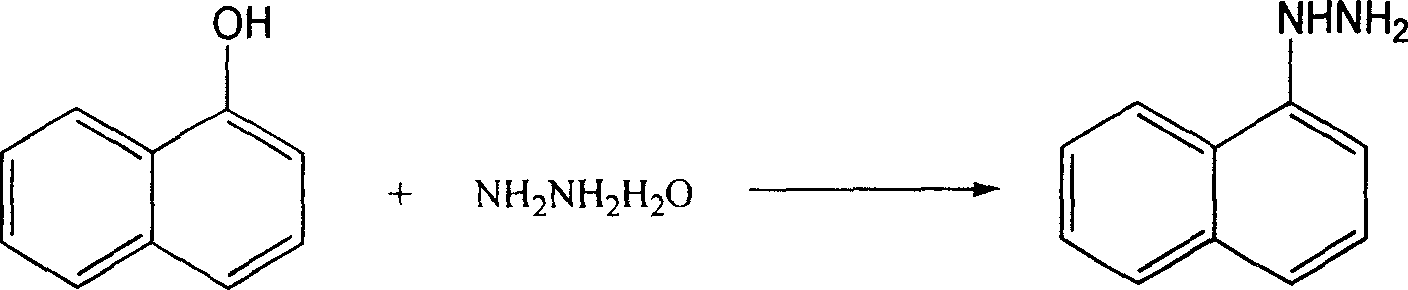

1-naphthylhydrazine preparation method

InactiveCN1800151ANo pollution in the processRaw materials are easy to getHydrazine preparationOrganic synthesisHydrazine compound

The invention relates to a method for synthesizing 1-naphthalene hydrazine in the field of organic synthesizing technology. The method uses 1-naphthalene hydrazine and hydrazine hydrate as raw material and the inactive gas to protect it to heat stir at normal pressure or pressured condition to obtain the 1-naphthalene hydrazine.

Owner:FUDAN UNIV

Substrate for PVC root growth promoting container seedling raising of Liquidambar styraciflua and preparation method thereof

InactiveCN107473800AHigh speedQuality improvementBio-organic fraction processingBioloigcal waste fertilisersAcetic acidRoot growth

The invention discloses a substrate for PVC root growth promoting container seedling raising of Liquidambar styraciflua and a preparation method thereof. A base substrate is prepared by composite fermentation of mixed barks, moss, straw, charred rice husk, sawdust, rotted leaves, 1-naphthalene acetic acid, domestic fungus dregs, Chinese medicine residues, a nitrogen-phosphorus-potassium compound fertilizer, microbial floras, and the like; high temperature disinfection and chemical disinfection treatment are carried out before usage. Compared with traditional cutting propagation and tissue culture technology, rooting speed and rooting quality of cutting of Liquidambar styraciflua are effectively promoted, and the problems of few roots, rooting difficulty, and low survival rate due to unbalanced nutrition of traditional cutting substrate of Liquidambar styraciflua are overcome; compared with common substrates for PVC root growth promoting container seedling raising, comprehensive substrate nutrition is provided, seedling raising quality is promoted and water controlling capability is improved, and outstanding development is obtained for introduction of colored species Liquidambar styraciflua and promotion of PVC root growth promoting container seedling raising.

Owner:JURONG MAOSHAN JUFU GARDEN

Alantolactone derivative and salts thereof

ActiveCN106496169AHigh in vitro anticancer activityImprove tumor inhibition rateOrganic active ingredientsOrganic chemistryPhosphorous acidPhosphomolybdic acid

The invention provides an alantolactone derivative shown as formula (I). The acid for salt forming is inorganic acid or organic acid, the inorganic acid is selected from hydrofluoric acid, hydrochloric acid, hydrobromic acid, hydriodic acid, sulfuric acid, nitric acid, phosphoric acid, carbonic acid, boric acid, seleninic acid, phosphomolybdic acid, phosphorous acid and sulfurous acid, and the organic acid is selected from citric acid, maleic acid, D-malic acid, L-malic acid, DL-malic acid, L-lactic acid, D-lactic acid, DL-acid, oxalic acid, methanesulfonic acid, pentanoic acid, oleic acid, lauric acid, p-toluene sulfonic acid, 1-naphthalene sulfonic acid, 2-naphthalene sulfonic acid, phthalic acid, tartaric acid, malonic acid, succinic acid, fumaric acid, glycollic acid, mercaptan acid, glycine, sarcosine, sulfonic acid, nicotinic acid, methylpyridine acid, isonicotinic acid, benzoic acid or substituted benzoic acid.

Owner:NANKAI UNIV

Method for preparing naphthyl alkoxy silane monomers

ActiveCN106188125AReduce consumptionReduce distillation costsGroup 4/14 element organic compoundsTetraethyl orthosilicate1-Naphthalene

The invention relates to a method for preparing naphthyl alkoxy silane monomers. The method comprises the following step: mixing alkoxy silane, sodium and 1-naphthalene halide to be reacted to obtain naphthyl alkoxy silane in an organic solvent, wherein the alkoxy silane is selected any one of tetramethoxysilane, methyltrimethoxysilane, tetraethoxysilane and methyl triethoxysilane. The method is easy to operate.

Owner:JIUJIANG UNIVERSITY

Method for preparing 2-amino-1-naphthalene sulfonic acid

InactiveCN105017094AReduce production energy consumptionIncrease productionSulfonic acid preparation2-NaphtholHydrogen chloride

The invention discloses a method for preparing 2-amino-1-naphthalene sulfonic acid. According to the method, by using dried hydrogen chloride gas, m-xylene and 2-naphthol as raw materials, the obtained purity is high in purity which is over 96.3%. The product is white to light pink powder, wherein the total amine value (based on dry product) is over 98.5%, the content of 2-naphthylamine is less than 0.01%, the content of water is lower than 1.0% and the content of isomers is less than 1%. The method is high in reaction efficiency and short in production period and has a good market prospect.

Owner:广州威杰生物科技股份有限公司

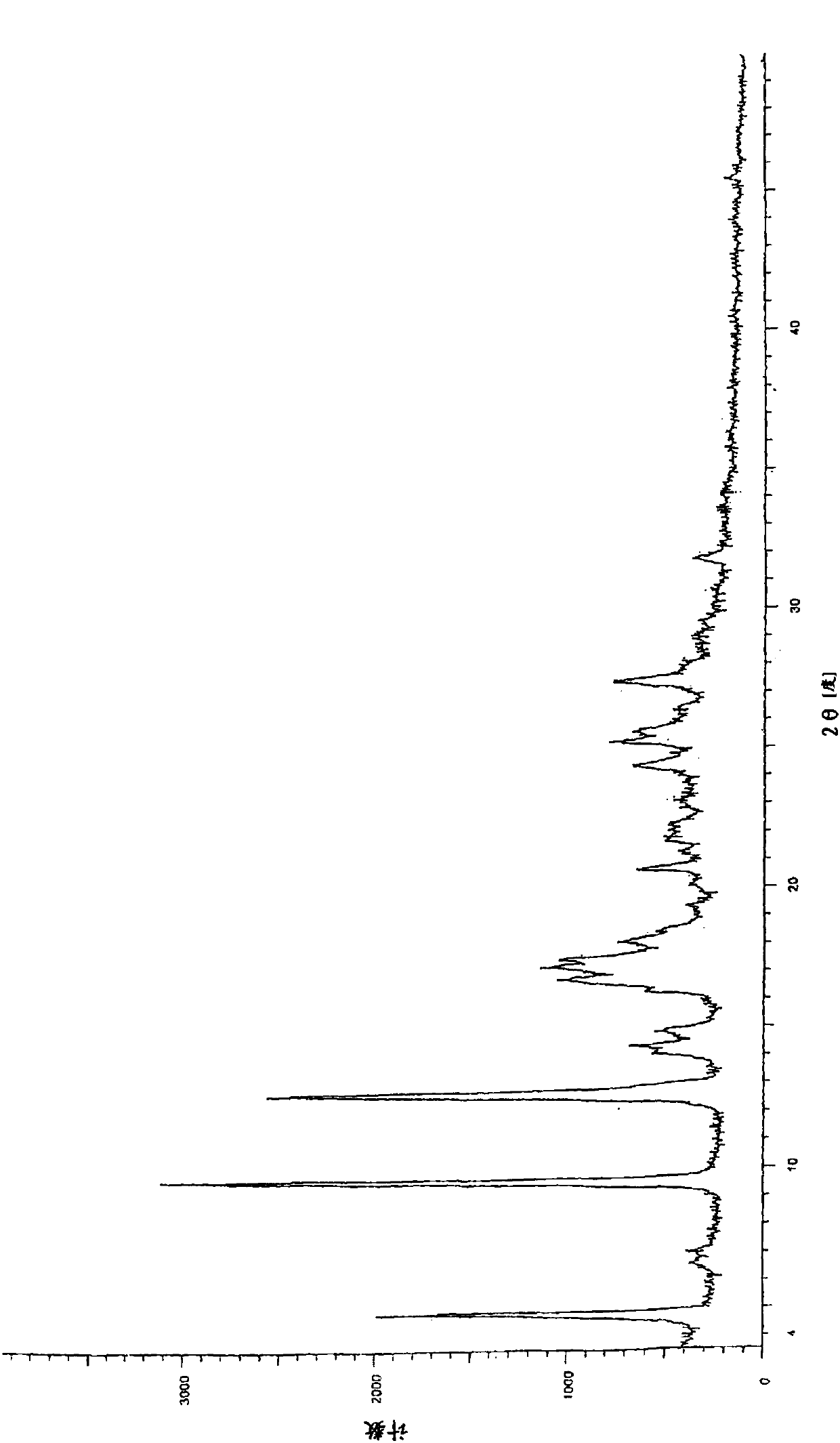

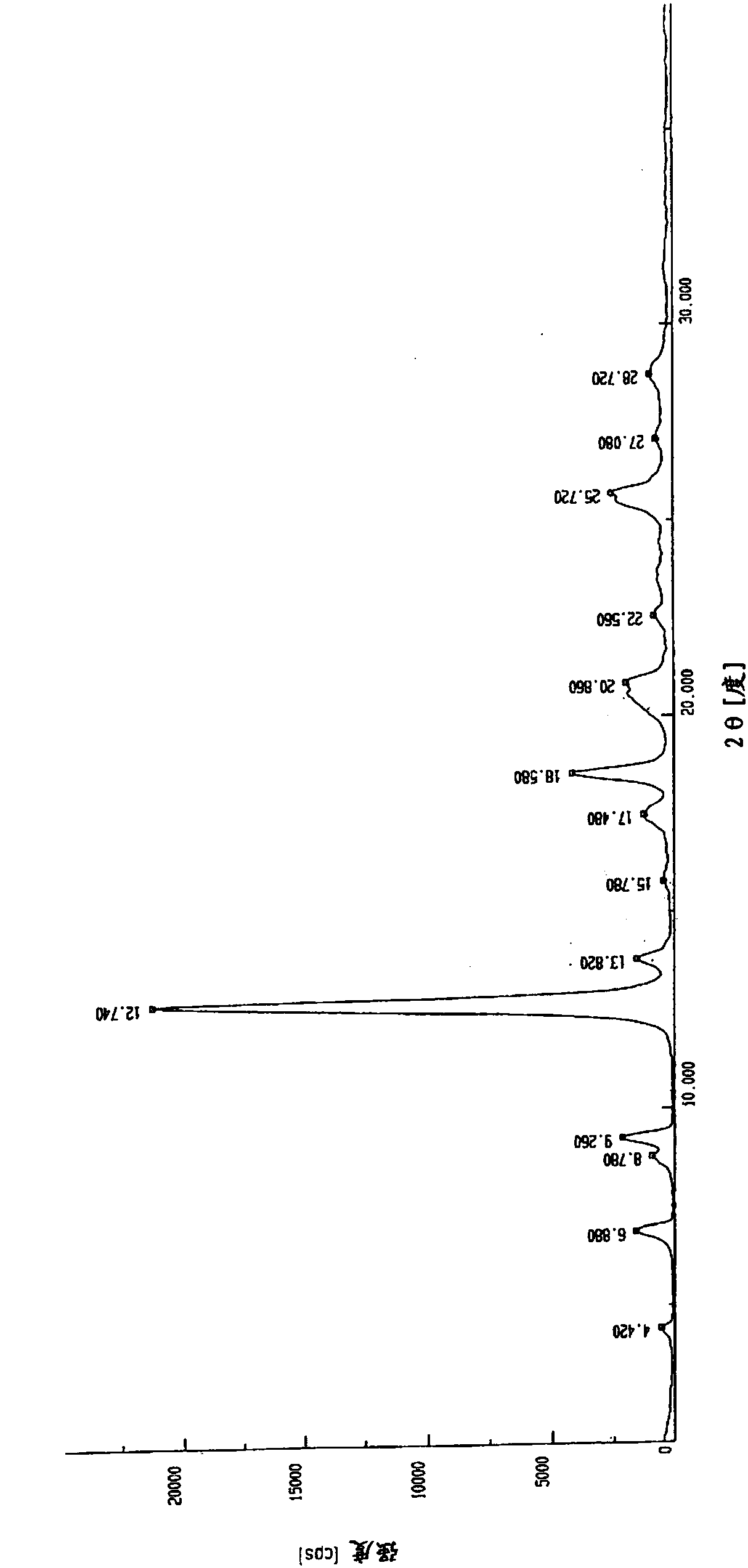

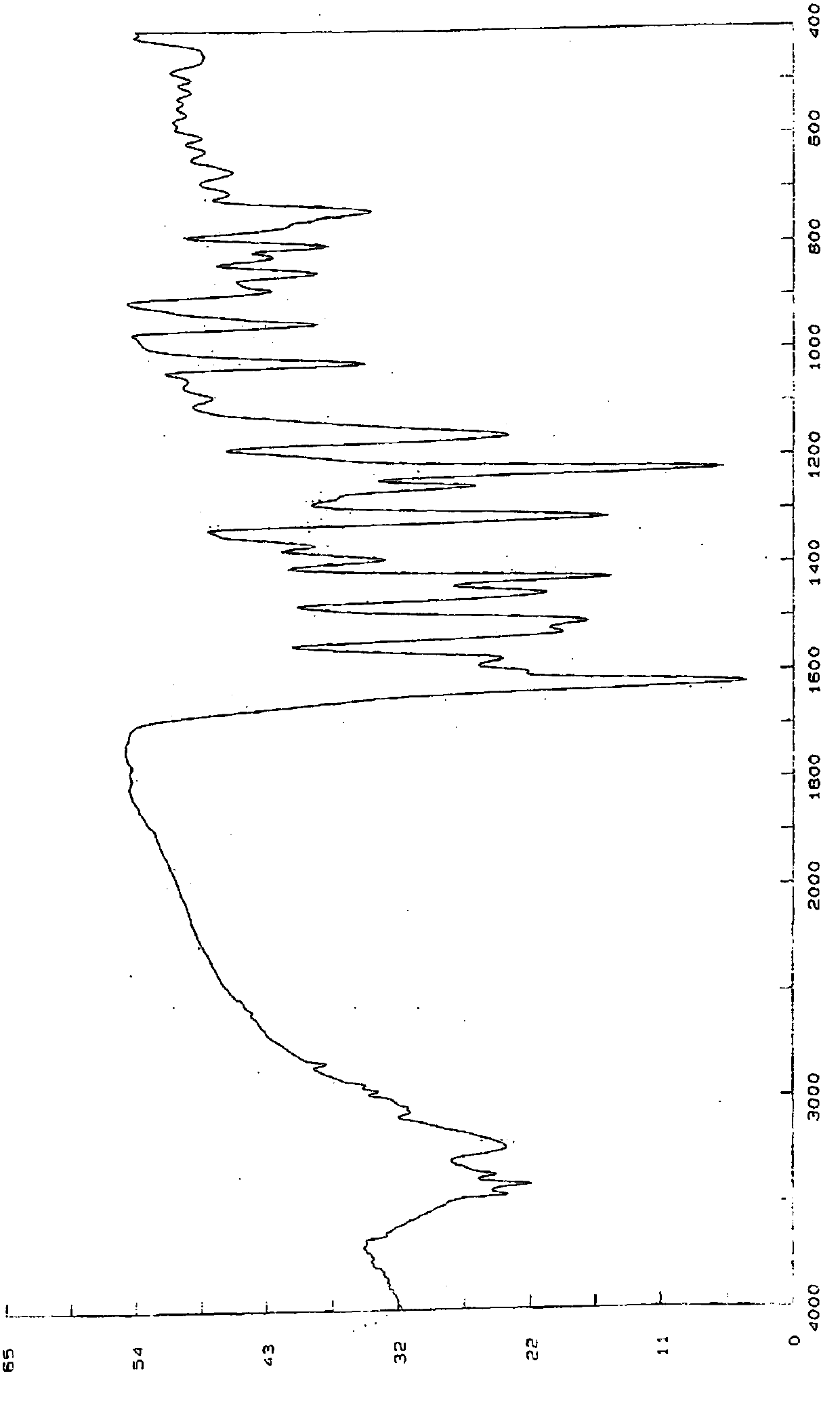

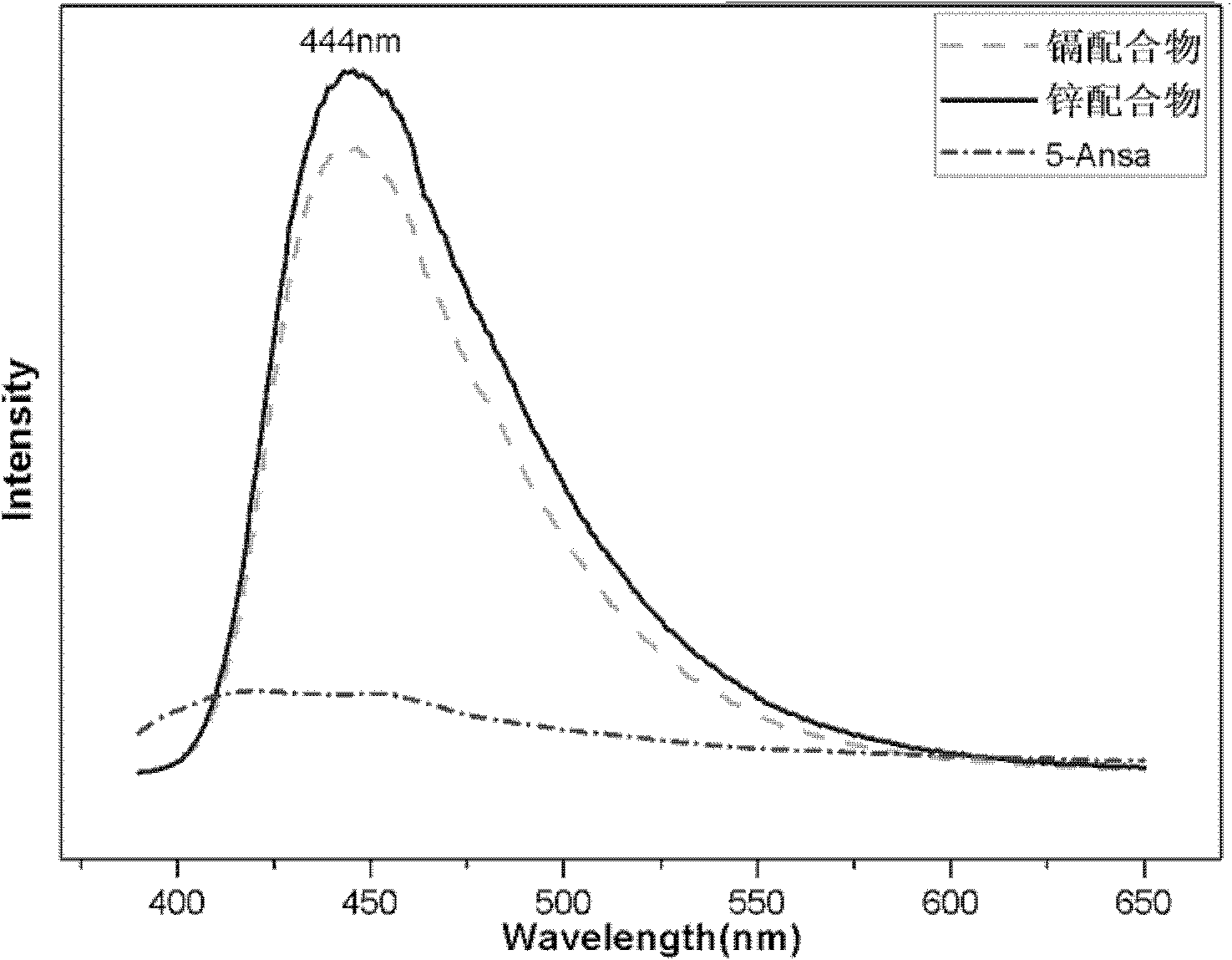

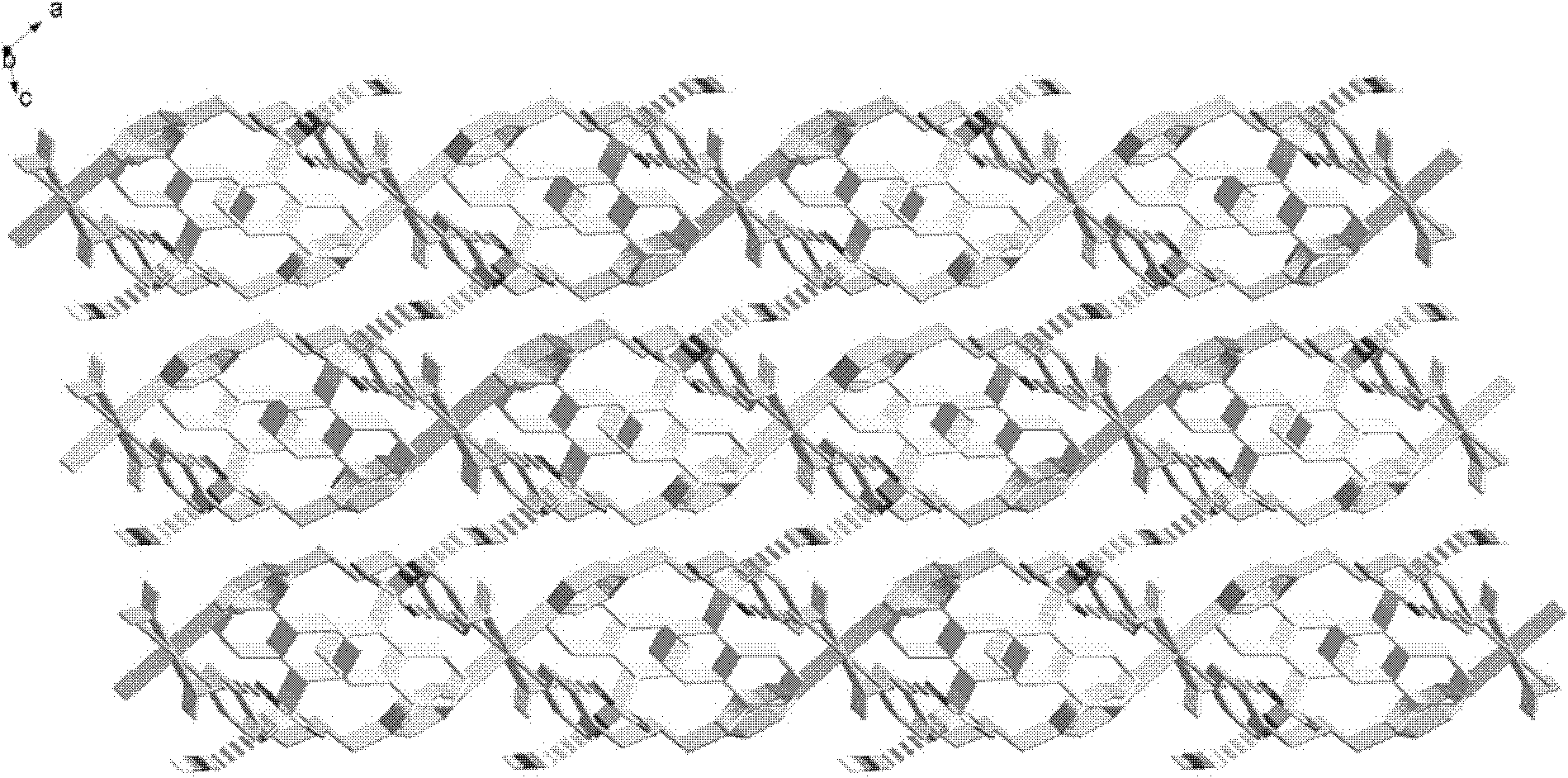

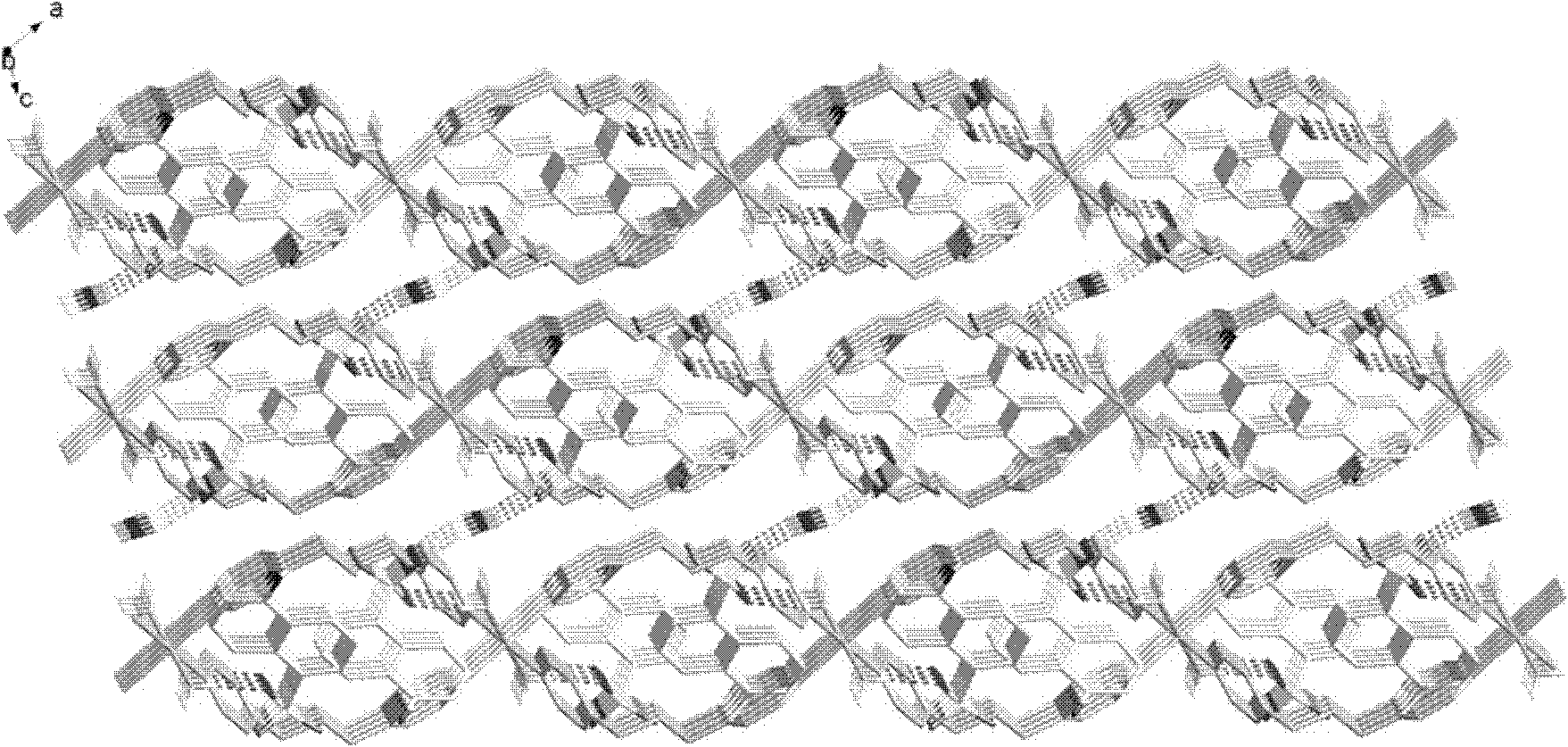

Fluorescent materials containing 5-amino-1-naphthalene-sulfonic acid and synthesis method thereof

InactiveCN103012448AImprove thermal stabilityLuminescent property regulationSolid-state devicesSemiconductor/solid-state device manufacturingQuantum yieldSynthesis methods

The invention provides fluorescent materials containing 5-amino-1-naphthalene-sulfonic acid and a synthesis method thereof and relates to the field of fluorescent materials. The fluorescent materials are two metal organic complexes containing 5-amino-1-naphthalene-sulfonic acid. The two metal organic complexes respectively have molecular formulas of {[Cd(4,4'-bpp)2(H2O)2].2(5-Ansa-).2H2O}n and {[Zn(4,4'-bpp)2(H2O)2].2(5-Ansa-).H2O}n, respectively are a light brown crystal and a reddish brown crystal, are synthesized by a solution method, and have high purity. According to the invention, at room temperature, the two metal organic complexes both can emit bright blue fluorescence under ultraviolet irradiation, have quantum yields of 10.5% and 13.0% respectively, and have strength obviously higher than strength of dissociative fluorescent molecules and a main metal organic frame. The synthesis method has the advantages of novel technology, simple processes, low equipment requirements, and low cost. Because the sample is in the state of crystals and has high purity, good heat stability, and good controllability of a structure and fluorescence, the fluorescent materials can be used as novel fluorescent materials and can be used for manufacture of fluorescent luminescent devices.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

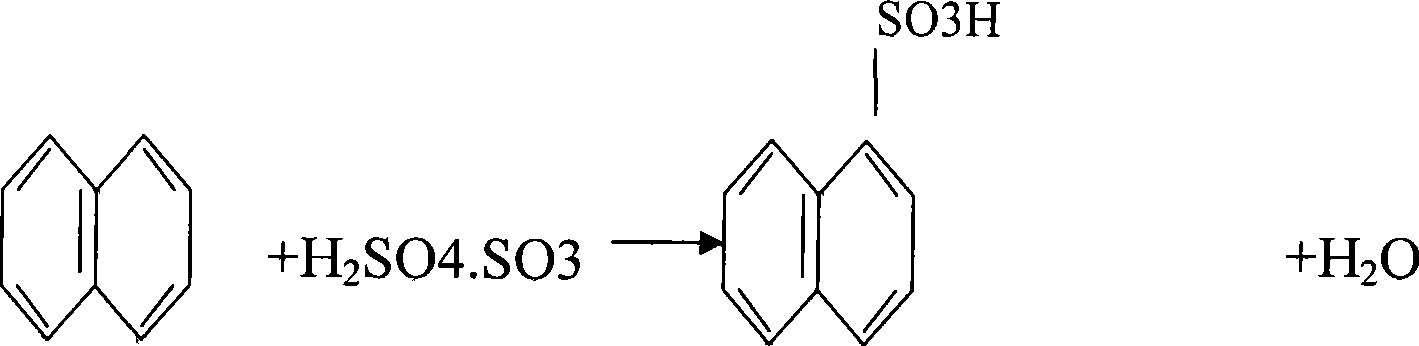

Process for the preparation of (6S)-(-)-5,6,7,8-tetrahydro-6-[propyl-(2-thienyl)ethyl]amino-1-naphthol (rotigotine)

ActiveUS20110306776A1Avoid reactionEasy to useOrganic active ingredientsOrganic chemistryAcetic acidAcetylation

The present invention describes a novel process for the preparation of (6S)-(−)-5,6,7,8-tetrahydro-6-[propyl-(2-thienyl)ethyl]amino-1-naphthol (Rotigotine) comprising: (a) acetylating (S)-(−)-5-hydroxy-N-n-propyl-2-aminotetraline to afford the acetate; (b) reacting this acetate, (−)-5-acetoxy-N-n-propyl-2-aminotetraline, with 2-(2-thienyl)ethanol 2-nitrobenzenesul-fonate; (d) hydrolyzing (6S)-(−)-1-acetoxy-5,6,7,8-tetrahydro-6-[propyl-(2-thienyl)ethyl]amino-1-naphthalene to afford (6S)-(−)-5,6,7,8-tetrahydro-6-[propyl-(2-thienypethyl]amino-1-naphthol (Rotigotine) and (d) purifying rotigotine either by the acetylation reaction and subsequent hydrolysis of the formed acetate or by salification of rotigotine through hydrochloride or hydrobromide formation and subsequent base release. Rotigotine is a dopamine agonist and is indicated for the treatment of Parkinson's disease.

Owner:INTERQUIM SA

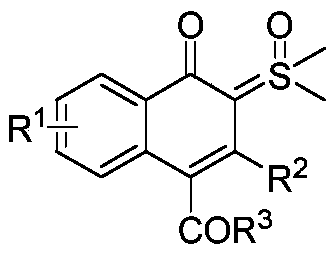

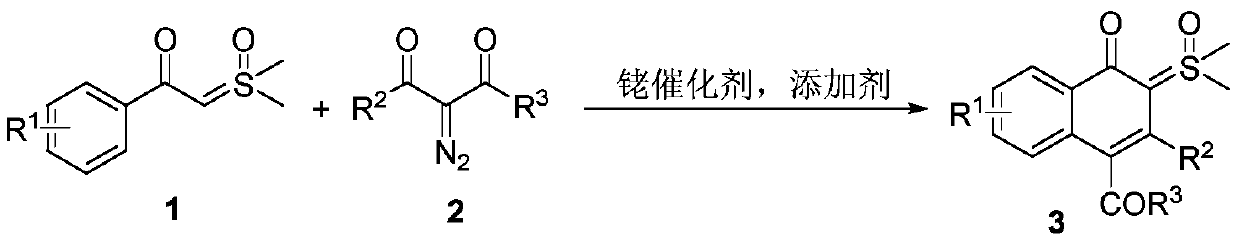

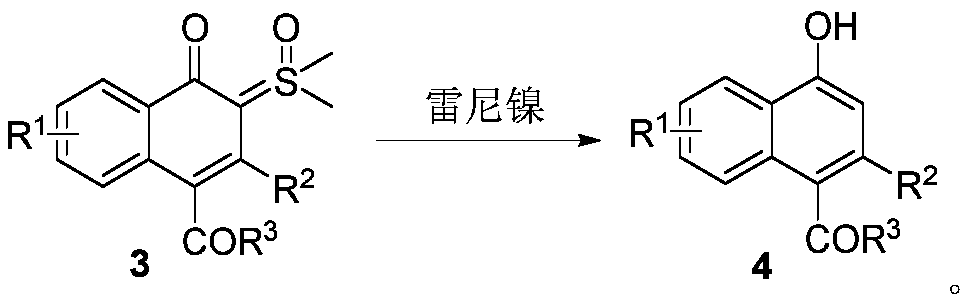

Synthesis and application of naphthalenone-sulfoxide ylide hybrid

ActiveCN109734642AEasy to operateAtom economy is highOrganic compound preparationCarboxylic acid esters preparationLithium chlorideP-Toluenesulfonic acid

The invention discloses a synthesis and an application of a naphthalenone-sulfoxide ylide hybrid and belongs to the technical field of organic chemistry. Firstly, the naphthalenone-sulfoxide ylide hybrid is synthesized through the cascade reaction between aryl formyl sulfoxide ylide and Alpha-diazo carbonyl compound. The hybrid is capable of efficiently generating 4-hydroxy-1- naphthalene carbonylderivative under the action of raney nickel, generating 3-hydroxy-4-oxo-1- naphthalene carbonyl derivative under the action of p-toluenesulfonic acid, efficiently synthesizing 4-hydroxy-3-sulfinyl-1-naphthalene carbonyl derivative under the action of lithium chloride and methanesulfonic acid and synthesizing 3,4-dioxo-1-naphthalene carbonyl derivative under the action of lithium chloride and sulfuric acid. Thus, the naphthalenone-sulfoxide ylide hybrid has deriving diversity and has an excellent application prospect.

Owner:HENAN NORMAL UNIV

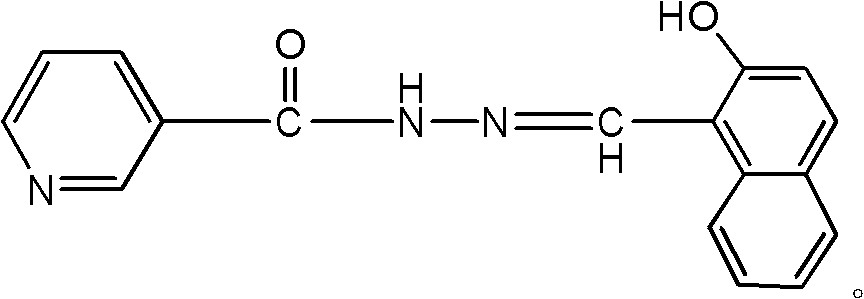

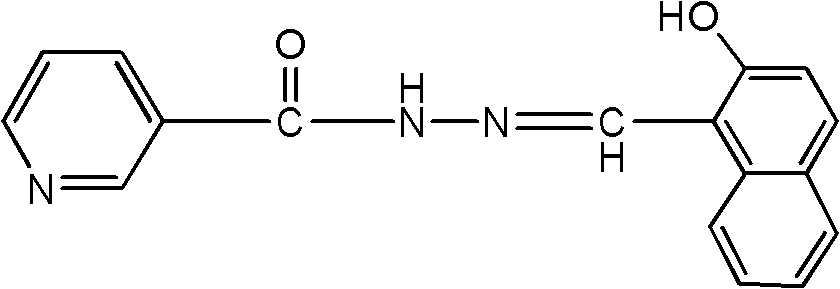

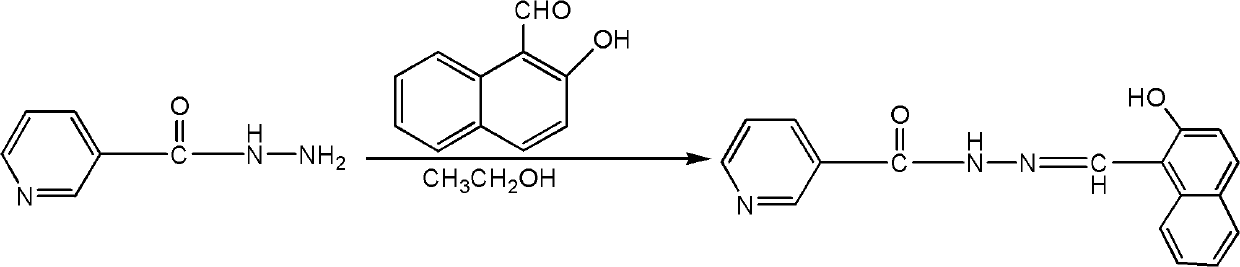

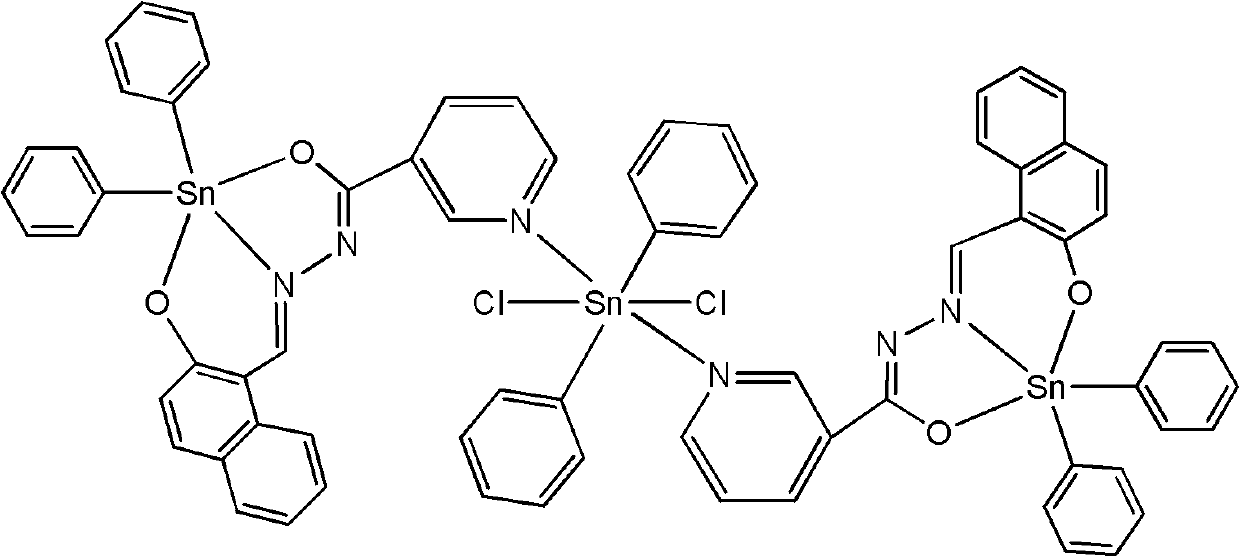

2-hydroxyl-1-naphthalene-3-pyridinecarbonylhydrazone and preparation method and applications thereof

InactiveCN102127013AImprove herbicidal activityIncrease fat solubilityBiocideOrganic chemistrySolubilityN dimethylformamide

The invention discloses 2-hydroxyl-1-naphthalene-3-pyridinecarbonylhydrazone of which structural formula is shown as below. The preparation method comprises the following steps: adding 10mmol of 3-picolinyl hydrazide and 20-30ml of methanol in a flask, refluxing and stirring to ensure that the hydrazide is completely dissolved, then adding 10mmol of 2-hydroxyl-1-naphthoic aldehyde to generate yellow precipitate instantly, reacting for 2-3 hours, cooling to the room temperature, performing suction filtering to obtain a hydrazone crude product; and then using the mixed solvent of absolute alcohol of which volume is 1:1 and N, N-dimethylformamide to recrystalliza and obtain yellow crystals; then washing with ethanol, and drying to obtain the pure product. The 2-hydroxyl-1-naphthalene-3-pyridinecarbonylhydrazone has higher herbicidal activity and can be used to prepare a herbicide for killing Echinochloa crusgalli, Digitaria sanguinalis, radish and rape. The product of the invention is characterized by high herbicidal activity, good liposolubility, high water solubility, low cost, simple preparation method and the like and a new way is provided for the development of the herbicide.

Owner:LIAOCHENG UNIV

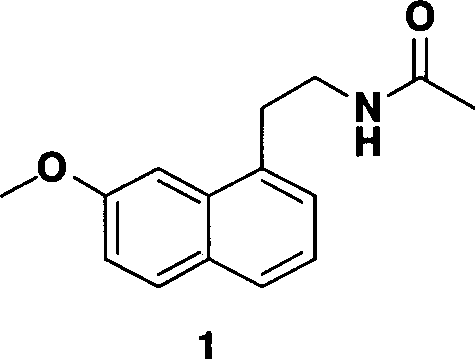

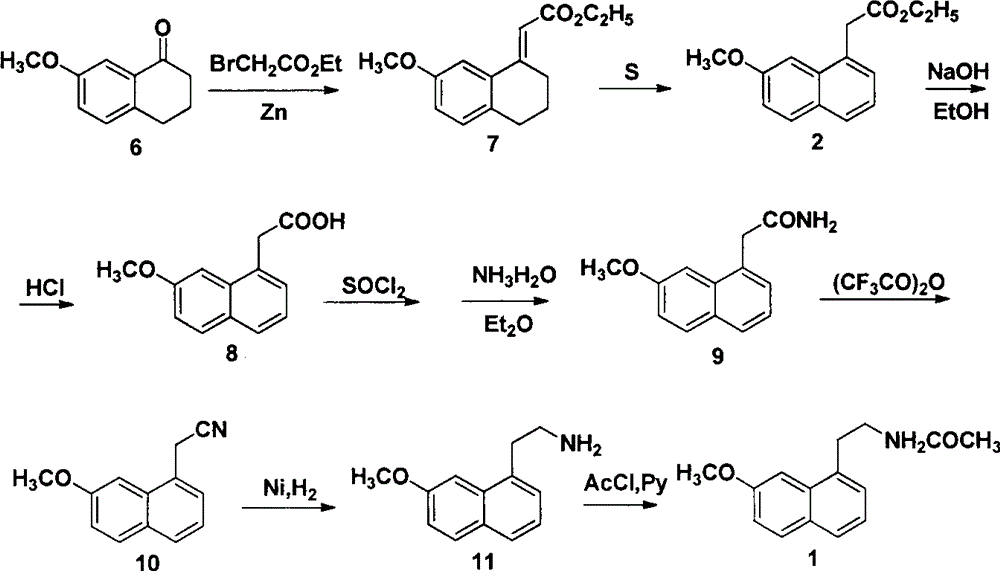

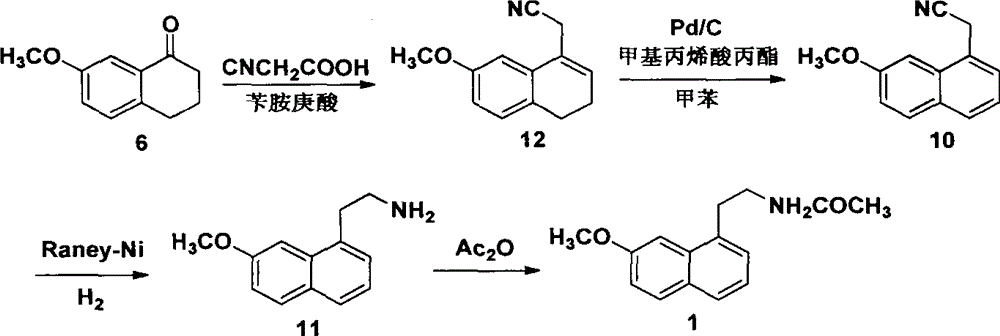

A new method for synthesizing agomelatine

ActiveCN102993040BEasy to buyEasy to separate and purifyOrganic compound preparationCarboxylic acid amides preparationSodium azideEthyl acetate

The invention relates to a novel method for synthesizing agomelatine, comprising the steps of: based on 7-methoxy-1-naphthalene ethyl acetate (formula 2) as an initial raw material, obtaining 7-methoxy-1-naphthalene ethanol (formula3) through reduction, obtaining 7-methoxy-1-naphthalene ethyl methane sulfonate (formula 4) through methylsulfonylation reaction, reacting 7-methoxy-1-naphthalene ethyl methane sulfonate (formula 4) with sodium azide to obtain 1-(2-azide ethyl)-7-methoxynaphthalene (formula 5) and finally directly acetylizing 1-(2-azide ethyl)-7-methoxynaphthalene (formula 5) to obtain the end product: agomelatine. The method has the advantages of easiness in raw material obtaining, short synthetic route, few reaction steps, mild reaction conditions and easiness in separation and purification of each intermediate and is suitable for industrial production.

Owner:CHINA PHARM UNIV

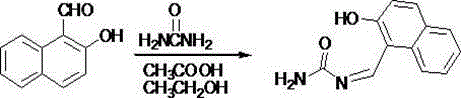

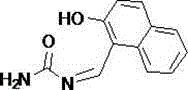

Method for rapid detection of metal Al<3+>

InactiveCN105092505AQuick checkEasy to operateChemical analysis using titrationColor/spectral properties measurementsAnhydrous ethanol1-Naphthalene

The invention discloses a method for rapid detection of metal Al<3+>, and relates to the ion detection technical field. A synthetic method comprises the steps: including 2-hydroxyl-1-naphthalene formaldehyde urea and anhydrous ethanol, during preparation, weighing 2-hydroxyl-1-naphthalene formaldehyde urea, dissolving with anhydrous ethanol to prepare a 0.01 M mother liquid, and then diluting to 2.5*10<-6> M with anhydrous ethanol. The method is prone to realization of rapid detection and easy and fast to operate, the preparation method is simple, the time is saved, and the measurement data are accurate.

Owner:YANCHENG TEACHERS UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Process for the preparation of (6S)-(-)-5,6,7,8-tetrahydro-6-[propyl-(2-thienyl)ethyl]amino-1-naphthol (rotigotine) Process for the preparation of (6S)-(-)-5,6,7,8-tetrahydro-6-[propyl-(2-thienyl)ethyl]amino-1-naphthol (rotigotine)](https://images-eureka.patsnap.com/patent_img/cb5f4fd9-e258-4d61-84da-2cec7c2fc7e9/US20110306776A1-20111215-C00001.png)

![Process for the preparation of (6S)-(-)-5,6,7,8-tetrahydro-6-[propyl-(2-thienyl)ethyl]amino-1-naphthol (rotigotine) Process for the preparation of (6S)-(-)-5,6,7,8-tetrahydro-6-[propyl-(2-thienyl)ethyl]amino-1-naphthol (rotigotine)](https://images-eureka.patsnap.com/patent_img/cb5f4fd9-e258-4d61-84da-2cec7c2fc7e9/US20110306776A1-20111215-C00002.png)

![Process for the preparation of (6S)-(-)-5,6,7,8-tetrahydro-6-[propyl-(2-thienyl)ethyl]amino-1-naphthol (rotigotine) Process for the preparation of (6S)-(-)-5,6,7,8-tetrahydro-6-[propyl-(2-thienyl)ethyl]amino-1-naphthol (rotigotine)](https://images-eureka.patsnap.com/patent_img/cb5f4fd9-e258-4d61-84da-2cec7c2fc7e9/US20110306776A1-20111215-C00003.png)