Method for extracting plant sterol from plant oil asphalt

A technology of vegetable oil asphalt and phytosterols, which is applied in the field of extracting phytosterols, can solve the problems of low product cost, and achieve the effects of low cost, easy access to solvents, and broad prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

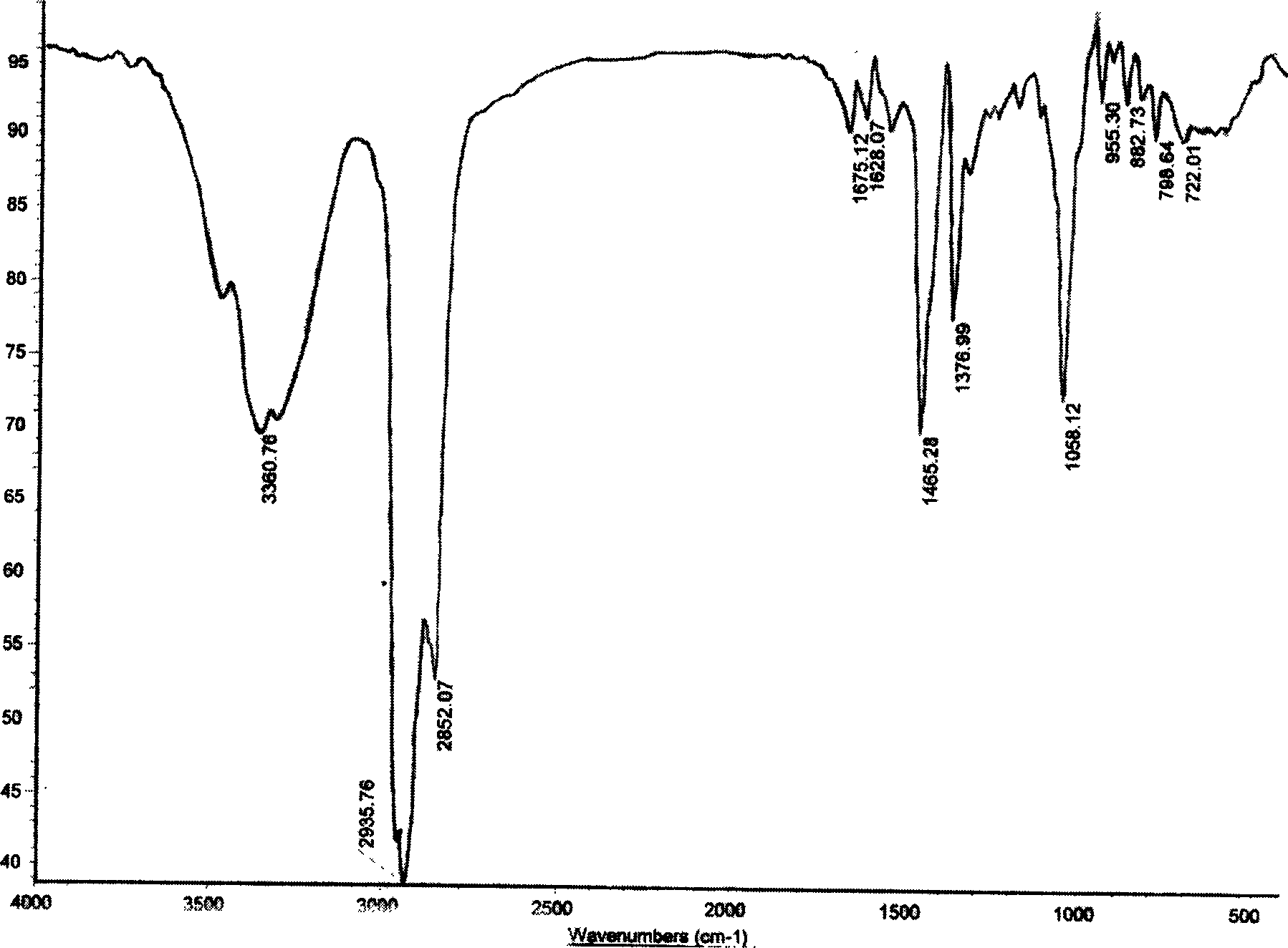

Image

Examples

Embodiment 1

[0020] Add 1kg of vegetable oil asphalt, 640ml of methanol and 50ml of concentrated sulfuric acid into a reaction kettle with a stirrer, reflux condenser and heating jacket, heat to 68°C under the conditions of stirring and reflux, and then heat for 3 hours, add 640ml of 80°C hot water, continue to heat the reflux reaction mixture for 10 minutes, stop the reaction, the reactant is cooled to room temperature, and the reactant is separated into layers. The water, sulfuric acid and methanol phase of the lower layer were discarded to obtain the upper oil layer, which contained most of the sterols and sterol esters and fatty acid esters esterified by methanol, so they were separated and collected.

[0021] Wash the oil layer with hot water at 90°C until neutral, pour the obtained neutral oil layer and 2.0L of methanol into the reaction kettle, extract in a conventional extraction system, add 150g of potassium hydroxide at 65°C, and continue the reflux reaction for 2.5 hours When co...

Embodiment 2

[0025] Add 1kg of vegetable oil asphalt, 450ml of methanol and 50ml of concentrated sulfuric acid into a reaction kettle with a stirrer, a reflux condenser and a heating mantle, heat to 68°C under stirring and reflux, and then heat the reaction for 3 hours, add 450ml of 80 ℃ hot water, continue to heat and reflux the reaction mixture for 10 minutes, stop the reaction, cool the reactant to room temperature, and the reactant is separated into layers. The water, sulfuric acid, and methanol phase of the lower floor were discarded to obtain the upper oil layer; all the other extraction steps were the same as in Example 1, resulting in 53.5g of crude sterols with a melting point of 138°C and an extraction rate of sterols of 5.35%.

Embodiment 3

[0027] Add 5.2kg of vegetable oil asphalt, 3.0L of methanol and 200ml of concentrated sulfuric acid into a reaction kettle with a stirrer, a reflux condenser and a heating mantle, heat to 70°C under the conditions of stirring and reflux, and then heat the reaction for 2 hours, add 3.0L of hot water at 100°C, continue to heat and reflux the reaction mixture for 10 minutes, stop the reaction, cool the reactant to room temperature, and the reactant is separated into layers. The water, sulfuric acid and methanol phase of the lower layer were discarded to obtain the upper oil layer, which contained most of the sterols and sterol esters and fatty acid esters esterified by methanol, so they were separated and collected.

[0028] Wash the oil layer with hot water at 90°C until neutral, pour the obtained oil layer and 7.8L of methanol into the reactor, extract in a conventional extraction system, add 780g of potassium hydroxide at 65°C, and continue the reflux reaction for 4.5 hours. W...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com